System and method for rapid preparation of ammonia water

A preparation system and ammonia water technology, applied in the field of chemical production, can solve the problems of non-circulation in the configuration process, ineffective water seal, complex process and equipment, etc., to achieve convenient disassembly and cleaning, prevent escape, and simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

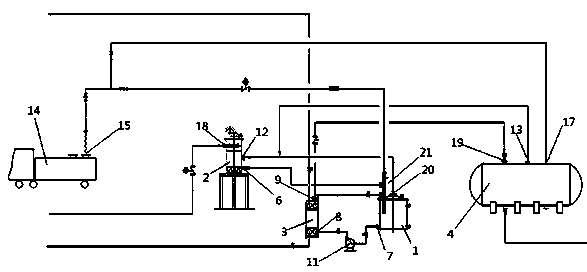

[0039] see figure 1 and figure 2 , the ammonia water rapid preparation system ammonia water preparation tank 1, ammonia absorption tower 2, cooling heat exchanger 3, ammonia water storage tank 4;

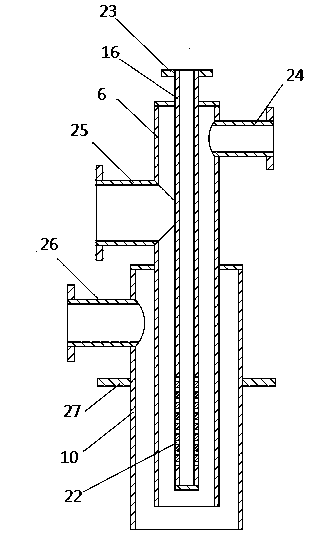

[0040] The ammonia water preparation tank 1 is provided with a diluter 21 extending into the ammonia water preparation tank 1 inside, and the diluter 21 includes a liquid ammonia delivery pipe 16, a new water pipe 6, and a circulating ammonia water pipe 10, and they are arranged on a coaxial center line. The new water pipe 6 and the circulating ammonia water pipe 10 are sequentially socketed outside the liquid ammonia delivery pipe 16, and they are arranged on the coaxial center line; the lower port of the liquid ammonia delivery pipe 16 is closed, and there is a discharge hole 22 at the lower end of the pipe wall; the new water pipe 6 and the lower end of the circulating ammonia water pipe 10 are internally connected with the ammonia water preparation tank 1, and the lower end ou...

Embodiment 2

[0047] A method for preparing ammonia based on the preparation system described in Example 1, comprising the steps of:

[0048] (1) Connect the circulating cooling water system to the cooling heat exchanger and turn on the circulating water cooling system;

[0049] (2) Open the new water intake regulating valve and keep the predetermined water supply at 25-30t / h;

[0050] (3) When the liquid level in the ammonia water preparation tank reaches 550-650mm, start the circulation pump;

[0051] (4) Open the liquid ammonia regulating valve, first slowly increase the opening of the liquid ammonia inlet regulating valve within 10% of its total opening, and control the mass percentage concentration of ammonia water in the ammonia water preparation tank to 1-10%; when the liquid ammonia After the ammonia flow rate is stabilized at 3-5t / h, continue to slowly increase the opening of the liquid ammonia feed regulating valve, and control the mass percentage concentration of ammonia water i...

Embodiment 3

[0056] The engineering example that preparation system described in embodiment 1 prepares ammoniacal liquor is as follows:

[0057] Step is as described in embodiment 2, and concrete parameter is:

[0058] New water supply (controlled by fresh water regulating valve, flow meter display value) is 30t / h, liquid ammonia supply (controlled by liquid ammonia regulating valve, inverse calculation value) is 3.28t / h, ammonia water output is 33.28t / h, and the final configuration Ammonia concentration 11% (measured value, mass percentage). The inlet temperature of the ammonia water in the cooling heat exchanger is 33°C, and the outlet temperature of the ammonia water is 27°C (the temperature difference is 6°C). Ammonia water distribution system Ammonia circulation volume ~65m 3 / h, the circulating water volume of the circulating water cooling system is 100m 3 / h. The pressure of the liquid ammonia tanker is 0.5~0.6MPa (gauge pressure), and the pressure of the configured tank reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com