Nanometer refining method of Al-Si system aluminum alloy structure

An aluminum alloy, al-si technology, which is applied in the field of aluminum alloy material preparation, can solve the problems of serious inhalation tendency, coarse nucleation particles, and short refining time, and achieves improved strength and toughness, good thermal stability, and refinement. The effect of alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

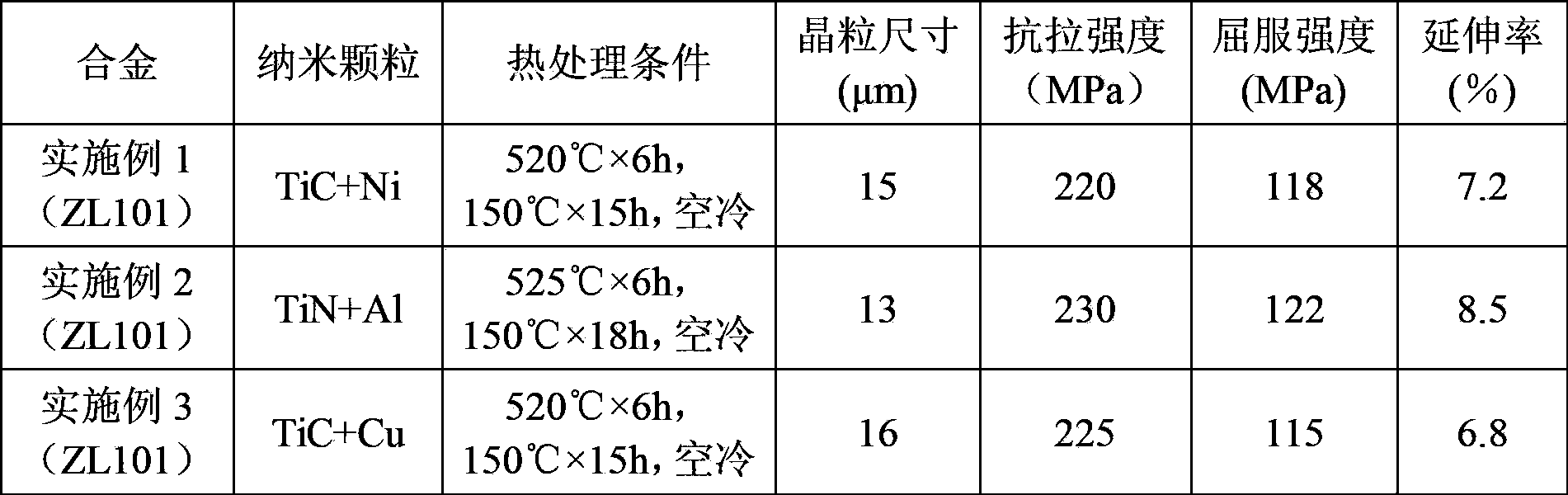

Embodiment 1

[0023] (a) Nanoparticle identification. Through performance and cost comparative analysis and chemical compatibility analysis, select TiC nanoparticles with high strength, good thermal stability, and moderate material cost, with an average particle size of 60nm;

[0024] (b) Pretreatment of nanoparticles. Use chemical methods to carry out metal coating treatment on selected nanoparticles, and the surface coating metal is Ni to obtain pretreated nanoparticles, see figure 1 ;

[0025] (c) Melt the ZL101 aluminum alloy, raise the temperature to 730°C, pass in Ar gas for 10 minutes, and then keep it for 10 minutes;

[0026] (d) adding the nanoparticles treated in step (b) into the aluminum alloy melt, and mechanically stirring for 3 minutes, raising the temperature to 730°C, and keeping the temperature for 20 minutes;

[0027] (e) adopting metal mold casting to obtain aluminum alloy ingots;

[0028] (f) placing the aluminum alloy ingot prepared in (e) in a heat treatment furna...

Embodiment 2

[0032] (a) Nanoparticle identification. Through performance and cost comparative analysis and chemical compatibility analysis, select TiN nanoparticles with high strength, good thermal stability, and moderate material cost, with an average particle size of about 60nm;

[0033] (b) Pretreatment of nanoparticles. Carry out metal coating treatment on the selected nanoparticles, and the surface coating metal is Al to obtain pretreated nanoparticles;

[0034] (c) Melt the aluminum alloy, heat up to 740 ° C, pass through Ar gas for 5 minutes, and then keep it for 15 minutes;

[0035] (d) adding the nanoparticles treated in step (b) into the aluminum alloy melt, and mechanically stirring for 3 minutes, raising the temperature to 740° C., and keeping the temperature for 15 minutes;

[0036] (e) Casting to obtain alloy ingots;

[0037] (f) placing the alloy ingot prepared in (e) in a heat treatment furnace, the treatment temperature is 525°C, the holding time is 6 hours, and cooled ...

Embodiment 3

[0040] (a) Nanoparticle identification. Through performance and cost comparative analysis and chemical compatibility analysis, select TiC nanoparticles with high strength, good thermal stability, and moderate material cost, with an average particle size of about 60nm;

[0041] (b) Pretreatment of nanoparticles. Carrying out metal coating treatment on the selected nanoparticles, the surface coating metal is Cu, to obtain pretreated nanoparticles;

[0042] (c) Melt the ZL101 aluminum alloy, raise the temperature to 735°C, pass in Ar gas for 8 minutes, and then keep it for 12 minutes;

[0043] (d) adding the nanoparticles treated in step (b) into the aluminum alloy melt, and mechanically stirring for 3 minutes, raising the temperature to 750° C., and keeping the temperature for 10 minutes;

[0044] (e) Casting to obtain alloy ingots;

[0045] (f) placing the alloy ingot prepared in (e) in a heat treatment furnace, the treatment temperature is 530°C, the holding time is 6 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com