Preparation method of smearing type processed cheese and prepared smearing type processed cheese

A processed cheese, spread-type technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of high nutritional value of chicken liver, aggravated fishy smell, deepened color and so on, and achieve easy swallowing, fine texture, and shelf life. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

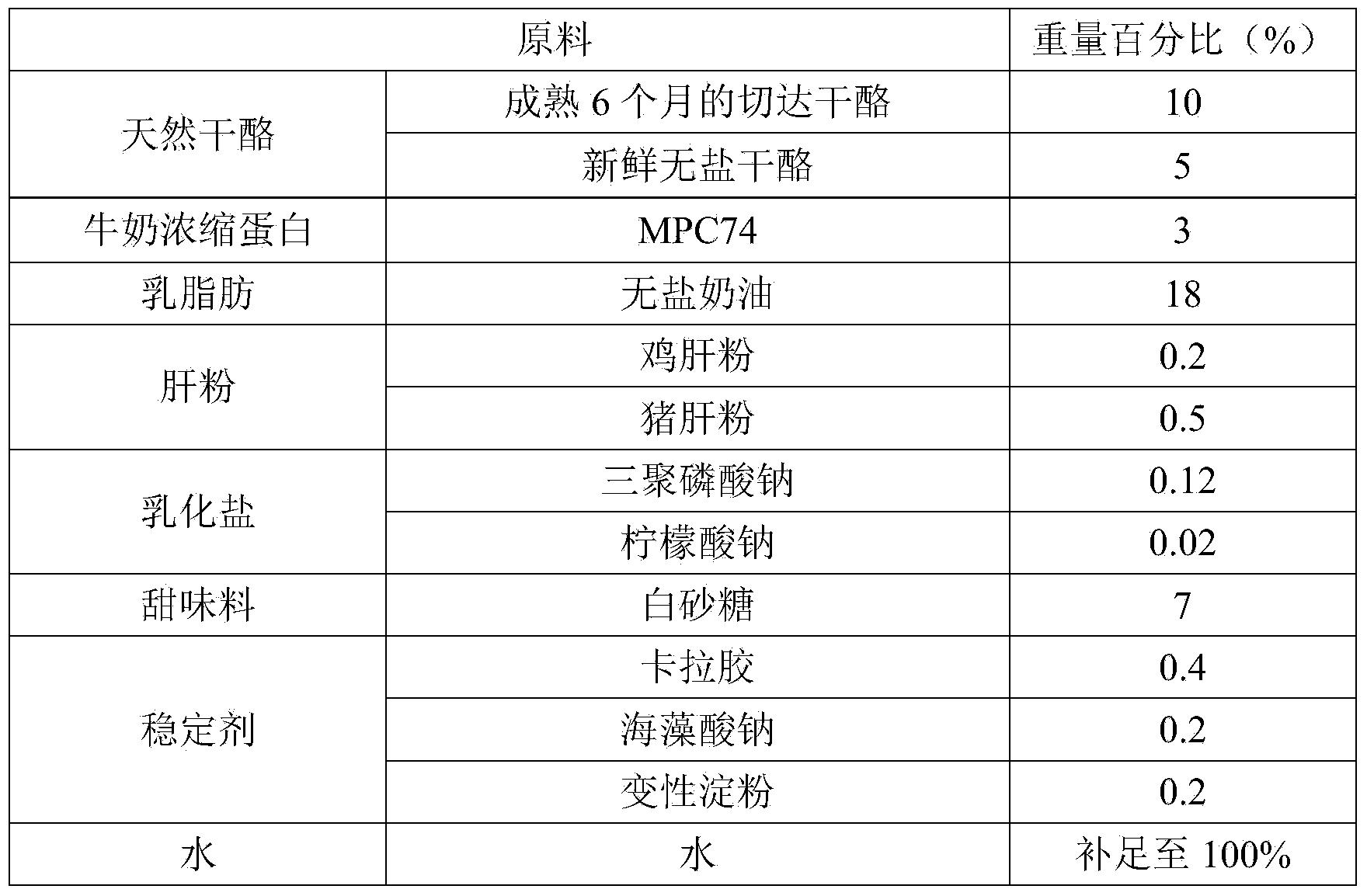

[0047] The raw material formula of the spreadable processed cheese of this embodiment is shown in Table 1.

[0048] The raw material formula of the spread type processed cheese of table 1 embodiment 1

[0049]

[0050] The preparation process of the spreadable processed cheese of the present embodiment is as follows:

[0051] (1) Cut the natural cheese into 1cm×1cm×8cm filaments, subdivide the unsalted butter, place them at room temperature for 15 minutes to soften them, and add emulsifying salt, Concentrate milk protein, liver powder and stabilizer, stir for 15 minutes, extrude the materials into thick noodles with a diameter of 1 cm and a length of 12 cm;

[0052] (2) Mix material A with white sugar and water, heat and melt; direct steam injection heating, heat up to 80°C within 3 minutes and completely melt (steam pressure 2.2bar); shear speed 3000rpm; degassing, vacuum degree 750mbar , time 30s;

[0053] (3) Ultra-pasteurize the melt (125°C, 10s);

[0054] (4) Cool ...

Embodiment 2

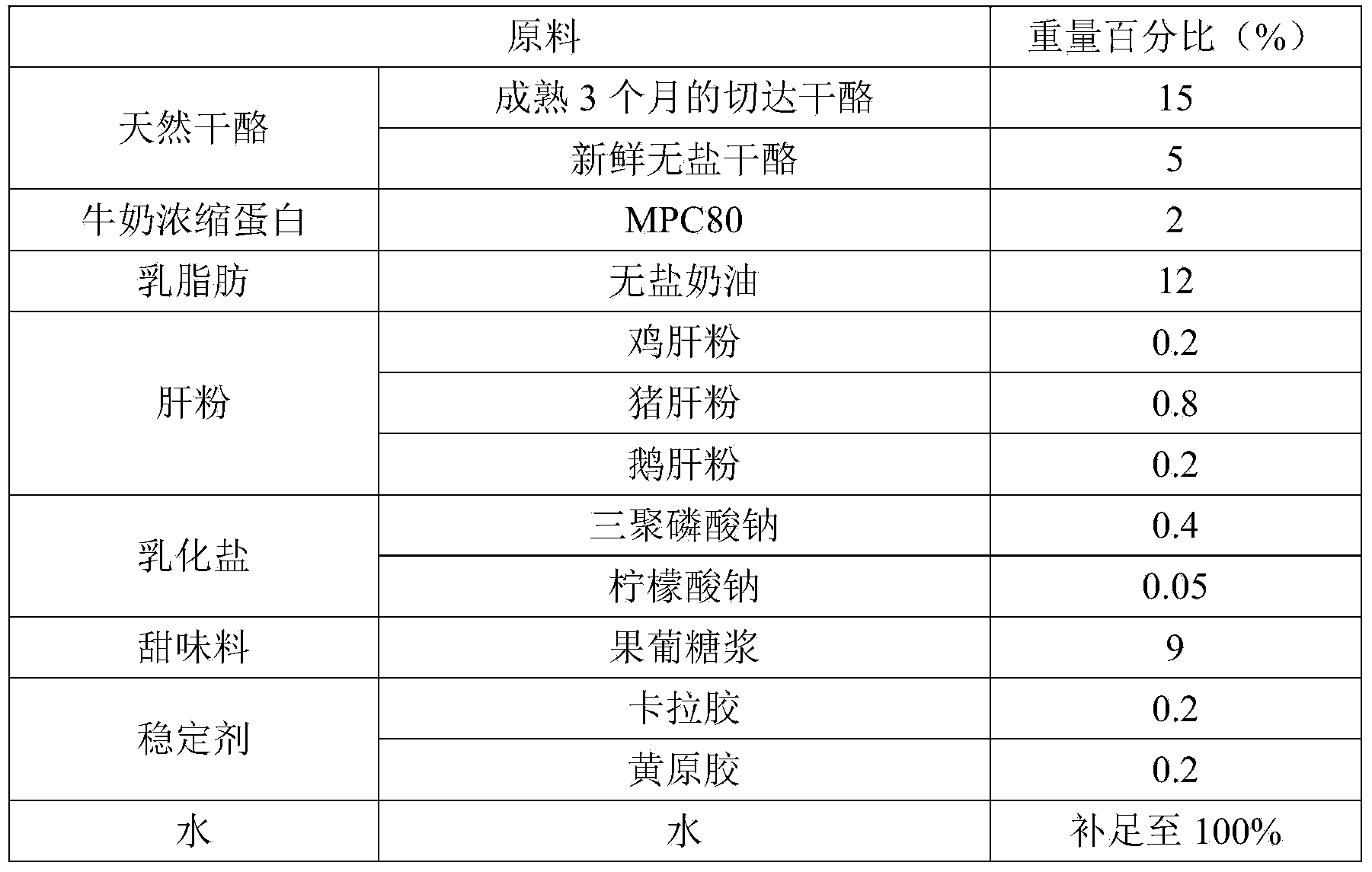

[0058] The raw material formula of the spreadable processed cheese of this embodiment is shown in Table 2.

[0059] The raw material formula of the spread type processed cheese of table 2 embodiment 2

[0060]

[0061] The preparation process of the spreadable processed cheese of the present embodiment is as follows:

[0062] (1) Cut the natural cheese into 1.5cm×1.5cm×6cm filaments, subdivide the unsalted butter and place them at room temperature for 20 minutes to soften them, and add emulsification while stirring the cheese constantly Salt, milk protein concentrate, liver powder and stabilizer, stir for 13 minutes, and extrude the materials into thick noodles with a diameter of 1 cm and a length of 10 cm;

[0063] (2) Mix material A with fructose syrup and water, heat and melt; heat up to 75°C within 3 minutes and melt completely (steam pressure 2.2bar); shear speed 3200rpm; degas, vacuum degree 850mbar, 15s;

[0064] (3) Ultra-pasteurize the melt (120°C, 5s);

[0065]...

Embodiment 3

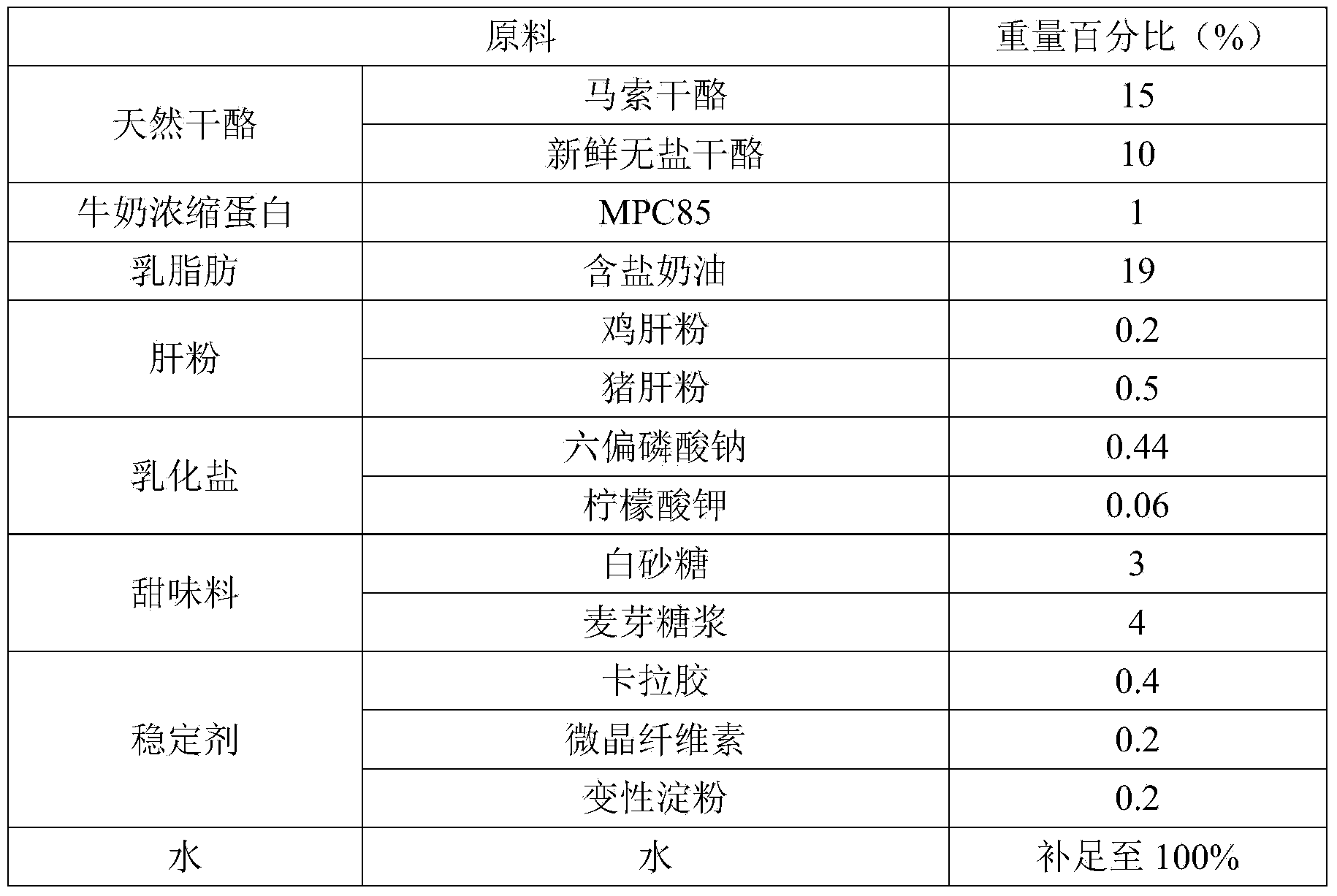

[0069] The raw material formula of the spreadable processed cheese of this embodiment is shown in Table 3.

[0070] The raw material formula of the spread type processed cheese of table 3 embodiment 3

[0071]

[0072] The preparation process of the spreadable processed cheese of the present embodiment is as follows:

[0073] (1) Cut the natural cheese into 1cm×1cm×5cm filaments, subdivide the salted butter, place it at room temperature for 20 minutes to soften it, and add emulsifying salt and milk concentrate while stirring the cheese constantly Egg white, liver powder and stabilizer, stirring for 15 minutes, extruding the materials into thick noodles with a diameter of 1 cm and a length of 10 cm;

[0074] (2) Mix material A with white sugar, malt syrup, and water, heat and melt, and heat up to 75°C within 3 minutes to melt completely; shear speed 3500rpm; degassing, vacuum degree 850mbar, 15s;

[0075] (3) Ultra-pasteurize the melt (124°C, 6s);

[0076] (4) Cool down t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com