Method for producing protein peptide and plasmin through fermentation of oreochromis niloticus skins and scales

The technology of tilapia and protein peptide is applied in the biological field, which can solve the problems of expensive addition and high production cost, and achieve the effects of low cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

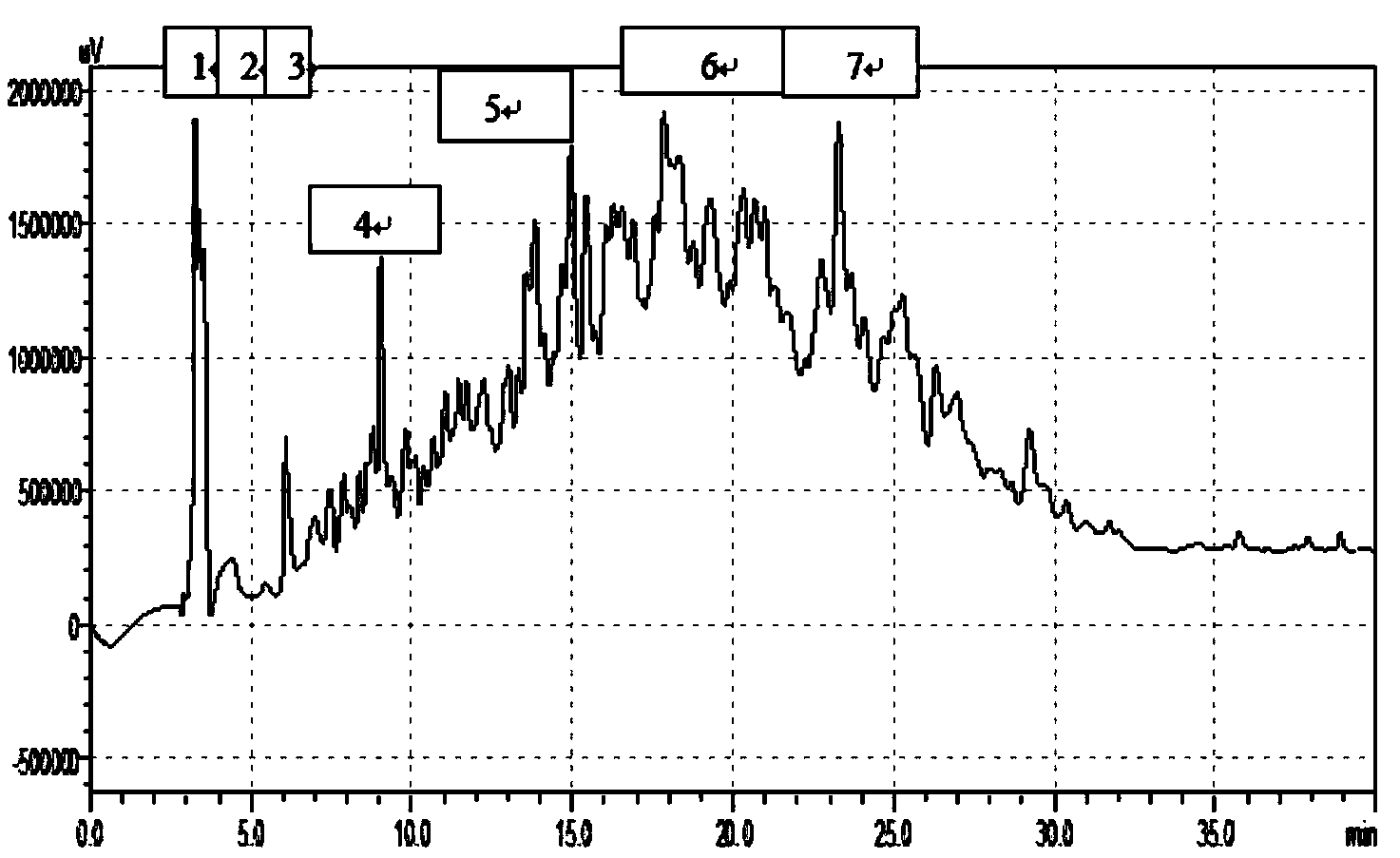

Image

Examples

Embodiment 1

[0029] Weigh 5kg of tilapia skin, wash and drain, add 40L of 0.2mol / L sodium hydroxide, soak for 30min to degrease, wash with water until neutral, crush and dry for use. Add fish skin and water to the fermenter at a solid-liquid mass ratio of 8:100, sterilize at 121°C for 30 minutes. Bacillus subtilis was inoculated with 2% of the inoculum, and the fermentation temperature was 35°C for 24 hours. At the end of the fermentation, the fermentation broth is filtered by plate frame to remove bacteria and impurities, and the filtrate is collected. The filtrate was ultrafiltered with a 5000 dalton ultrafiltration membrane, the filtrate was protein peptide, and the retentate was plasmin. The filtrate was concentrated in vacuo and spray-dried to obtain protein peptide powder. Plasmin was freeze-dried to obtain active enzyme powder.

Embodiment 2

[0031] Weigh 5kg of the mixture of tilapia skin and fish scales, wash and drain, add 60L of hydrochloric acid solution with a concentration of 0.4mol / L, soak for 30min to decalcify, wash with water until neutral and drain; then add 0.4mol / L sodium hydroxide 60 liters, soaked for 40 minutes to degrease, washed with water until neutral, crushed and dried for later use. Add the mixture of fish skin and fish scales and water to the fermentation tank at a ratio of solid-liquid mass ratio of 12:100, sterilize at 121° C. for 30 minutes. Bacillus subtilis was inoculated at an inoculum of 4%, and the fermentation temperature was 35°C for 36 hours. At the end of the fermentation, the fermentation broth is filtered by plate frame to remove bacteria and impurities, and the filtrate is collected. The filtrate was ultrafiltered with a 5000 dalton ultrafiltration membrane, the filtrate was protein peptide, and the retentate was plasmin. The filtrate was concentrated in vacuo and spray-drie...

Embodiment 3

[0033] Weigh 5kg of the mixture of tilapia skin and fish scales, wash and drain, add 60L of hydrochloric acid solution with a concentration of 0.6mol / L, soak for 30min to decalcify, wash with water until neutral and drain; add 80L of 0.6mol / L sodium hydroxide, Degreased for 60 minutes, washed with water until neutral, crushed and dried for later use. Add fish skin and water to the fermenter at a ratio of 10:100 solid to liquid, sterilize at 121°C for 30 minutes. 6% of the inoculum was inoculated with Bacillus subtilis, and the fermentation temperature was 35°C for 48 hours. At the end of the fermentation, the fermentation broth is filtered by plate frame to remove bacteria and impurities, and the filtrate is collected. The filtrate was ultrafiltered with a 5000 dalton ultrafiltration membrane, the filtrate was protein peptide, and the retentate was plasmin. The filtrate was concentrated in vacuo and spray-dried to obtain protein peptide powder. Plasmin was freeze-dried to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com