Double-component silicone structural sealant for heat mirror hollow glass and preparation method thereof

A two-component, sealant technology, used in the field of sealants, can solve the problem that the hardness, modulus, flame retardancy and thixotropy of the sealant cannot be met, and the adhesive force and curing time of the hot mirror film cannot be met. Wetness, mutual penetration force and weak bonding ability, etc., to achieve the effect of excellent heat insulation effect, high hardness and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

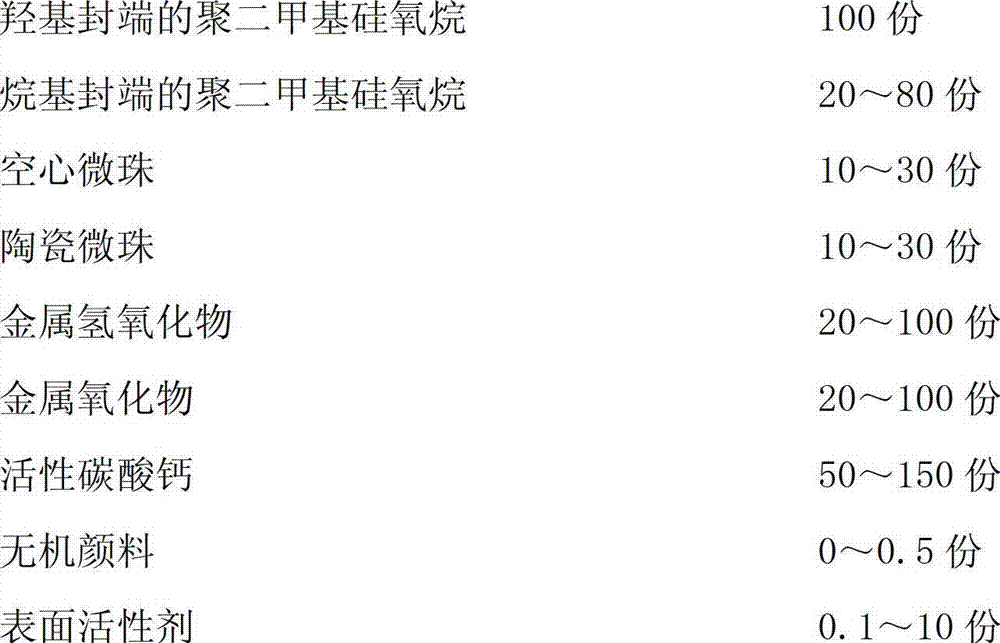

[0034] The white two-component silicone structural sealant for heat mirror insulating glass in this embodiment includes component A and component B, and the components and quality of component A are:

[0035]

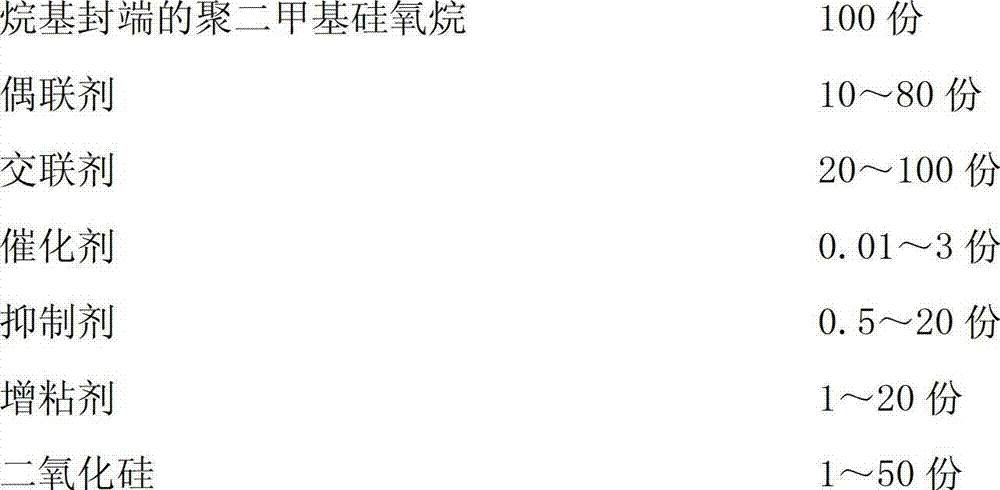

[0036] Each component and mass parts in the B component are:

[0037]

[0038]

[0039] The mass ratio of component A to component B is 8:1.

[0040] The tackifier is a silicone oligomer containing acyloxy groups with a degree of polymerization of 2. The preparation method is to add allyl acrylate to a mixed solution of low-hydrogen silicone oil and Pt catalyst for hydrosilylation reaction. The reaction temperature is The temperature is 60°C, the reaction time is 5h, and the solvent is removed after the reaction.

[0041] The preparation method of the two-component silicone structural sealant comprises the following steps:

[0042] 1) Weigh hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000cp, alkyl-terminated polydimethylsiloxane with a viscos...

Embodiment 2

[0046] The yellow two-component silicone structural sealant for heat mirror insulating glass of this embodiment includes component A and component B, and the components and quality of component A are:

[0047]

[0048]

[0049] Each component and mass parts in the B component are:

[0050]

[0051] The mass ratio of A component to B component is 14:1.

[0052] The tackifier is a silicone oligomer containing an epoxy group with a degree of polymerization of 4. The preparation method is to add allyl glycidyl ether to a mixed solution of low hydrogen-containing silicone oil and a Pt catalyst for hydrosilylation. The reaction temperature is 20°C, the reaction time is 9 hours, and the solvent is removed after the reaction.

[0053] The preparation method of the two-component silicone structural sealant comprises the following steps:

[0054] 1) Weigh hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000cp, alkyl-terminated polydimethylsiloxane with a viscosi...

Embodiment 3

[0058] The red two-component silicone structural sealant for hot mirror insulating glass in this embodiment includes component A and component B, and the components and quality of component A are:

[0059]

[0060]

[0061] Each component and mass parts in the B component are:

[0062]

[0063] The mass ratio of A component to B component is 20:1.

[0064] The tackifier is an alkoxy-containing silicone oligomer with a polymerization degree of 6. The preparation method is to add vinyltrimethoxysilane to a mixed solution of low hydrogen-containing silicone oil and Pt catalyst for hydrosilylation reaction. The reaction temperature is 120°C, the reaction time is 7 hours, and the solvent is removed after the reaction.

[0065] The preparation method of the two-component silicone structural sealant comprises the following steps:

[0066] 1) Weigh hydroxyl-terminated polydimethylsiloxane with a viscosity of 150,000 cp, alkyl-terminated polydimethylsiloxane with a viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com