Solid oxide fuel cell with symmetrical electrodes, and preparation method and application thereof

A solid oxide and fuel cell technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of low catalytic activity and long preparation period of impregnated electrodes, and achieve improved catalytic activity, short preparation period, The effect of eliminating carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] a) Preparation of porous electrolyte|dense electrolyte|porous electrolyte skeleton structure

[0050] to La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3 (LSGM) In the electrolyte powder 30g, add solvent absolute ethanol, butanone each 4g, dispersant triethanolamine 5g and acrylic acid copolymer 1g successively, binder epoxy resin 5g and plasticizer polyethylene glycol 4g; After mixing Obtain a uniform and stable slurry by ball milling, vacuum defoam the slurry, remove the air in the slurry, and tape cast to obtain a dense electrolyte layer green body;

[0051] To 30g of LSGM electrolyte powder, add solvent absolute ethanol, butanone 4g each, dispersant triethanolamine 5g and acrylic acid copolymer 1g, binder epoxy resin 5g, pore-forming agent ammonium oxalate 20g and plasticizer polyethylene 4 g of diol; after mixing, a uniform and stable slurry is obtained by ball milling, the slurry is vacuum defoamed, the air in the slurry is removed, and the porous electrolyte layer green body...

Embodiment 2

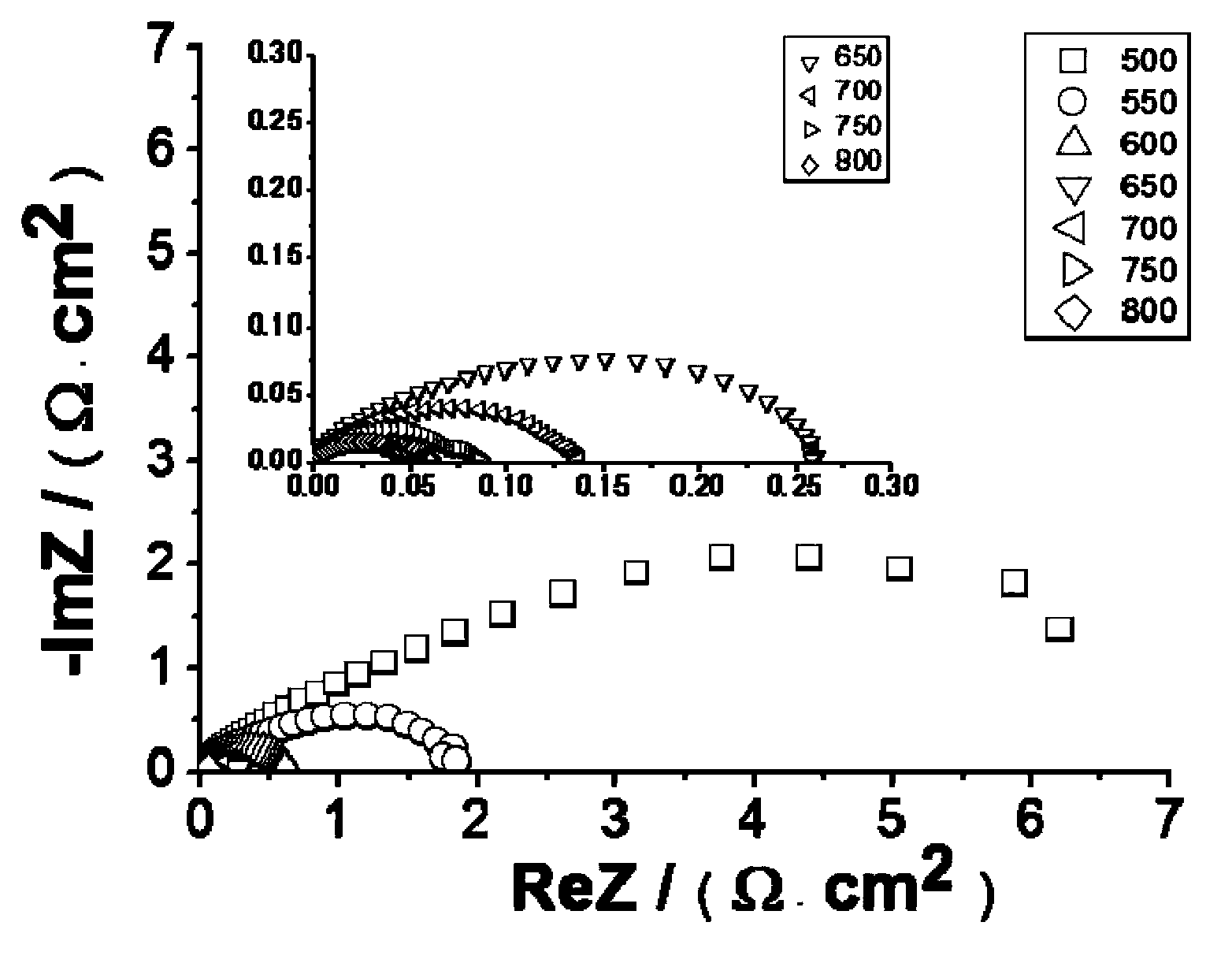

[0066] The preparation process is the same as in Example 1, except that the electrolyte material is replaced by YSZ (doped with 8wt% Y 2 o 3 ZrO 2 ). The porosity of the porous YSZ layer is about 55%, and the thickness of the dense YSZ layer is about 30 μm. The impregnated SFMO accounts for about 25% of the pore volume fraction of the porous layer.

[0067] The test conditions are the same as in Example 1. When hydrogen is used as fuel, the open circuit voltage of the single cell is between 1.021V and 1.07V in the range of 600-800°C, and the maximum output power at 600, 650, 700, 750, and 800°C are respectively 78, 130, 193, 250, 313mW·cm -2 between. When propane is used as fuel, the open circuit voltage of a single cell is between 0.9V and 0.88V in the range of 750-800°C, and the maximum output power at 750°C and 800°C is 74 and 155mW·cm respectively -2 between.

Embodiment 3

[0069] The preparation process is the same as in Example 1, except that the electrolyte material is replaced by ScSZ (doped with 10wt%Sc 2 o 3 ZrO 2 ), the electrocatalytic thin film electrode material was replaced by LaSr 2 Fe 2 CrO 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com