Offshore no-killing electric pump lifting process pipe string

A technology of process pipe string and electric pump, which is applied in cable terminals, wellbore/well components, wellbore/well valve devices, etc. Technology promotion, operation schedule impact and other issues, to achieve the effect of improving development effect, significant technical effect and economic benefit, and increasing oil recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

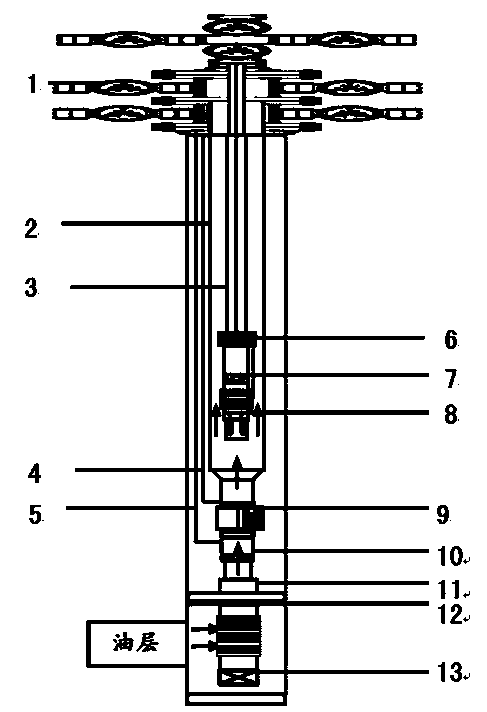

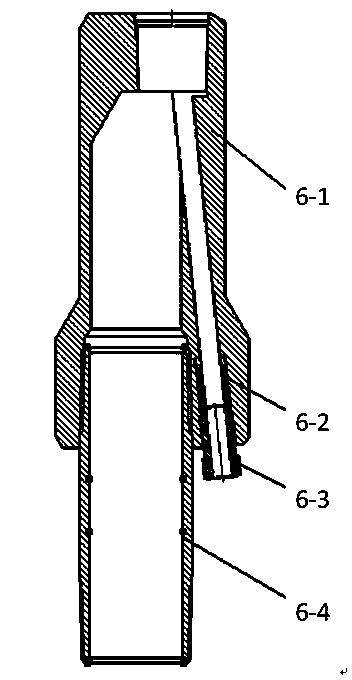

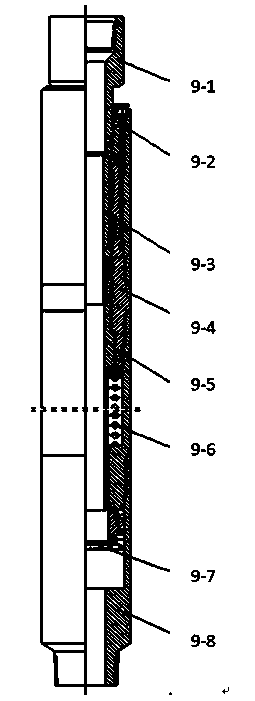

[0019] according to figure 1 As shown, an offshore snubbing electric pump lifting process string is composed of a production string and a control string that cooperate with each other. The control string includes a sand control and filter pipe 13 connected together from bottom to top, a filling seal Spacer 12, close-fitting device 11, pressure measuring and pressure transmitting cylinder 10, pressure transmitting capillary 5, downhole safety valve 9, hydraulic control pipeline 4, jointless collar casing 2, double-stage large cross 1, the pressure measuring The pressure transmission cylinder 10 is set at the lower end of the downhole safety valve 9, the close-fitting device 11 is set at the upper end of the packing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com