Gas transmission pipelines and semiconductor equipment

A transmission tube and semiconductor technology, applied in gas/liquid distribution and storage, semiconductor/solid-state device manufacturing, mechanical equipment, etc., can solve problems such as increasing costs, avoid temperature reduction, improve product yield, and eliminate formation defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

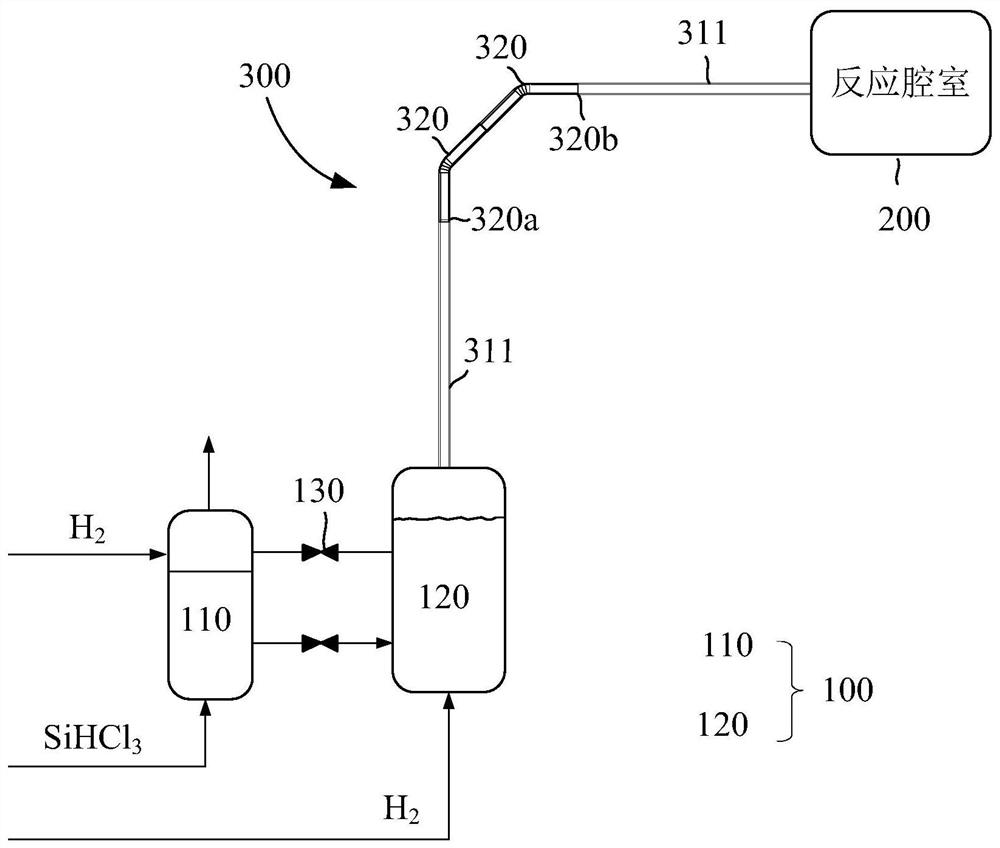

[0056] The inventors found that trichlorosilane is also called silicon chloroform, the trichloride of monosilane, Trichlorosilane, chemical formula SiHCl 3 , Melting point -126.5°C, boiling point 33°C. At room temperature, it is a colorless liquid that flows easily and has a density of 1.34g / cm 3 . Since the epitaxial process is a gas phase separation reaction, the liquid trichlorosilane at room temperature needs to use hydrogen as the carrier gas, and it is brought into the reaction chamber along with the gas delivery pipeline through the bubbling vaporizer.

[0057] For the liquid phase, a certain temperature corresponds to a certain gas phase partial pressure of the components. For the pure component trichlorosilane, the solubility of hydrogen in trichlorosilane is very small, and it can be considered as an inert gas approximately. Therefore, the partial pressure of trichlorosilane is just equal to the saturated vapor pressure of trichlorosilane of pure component, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com