Method and device for producing reduced iron through synthetic gas prepared from high-nitrogen content retort gas

A technology for dry distillation of gas and high nitrogen content, which is applied in the direction of catalytic treatment of combustible gas, gas dust removal, combustible gas purification, etc. The effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

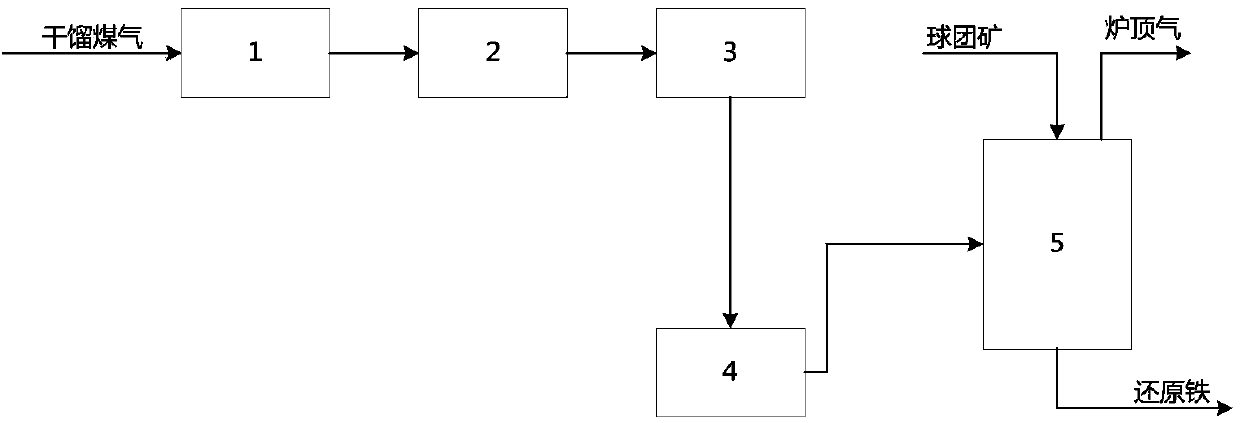

[0058] See figure 1 As shown, in this embodiment, a device for producing reduced iron by using carbonized coal gas with high nitrogen content to produce syngas is provided. The device mainly includes a dry distillation gas purifier 1, a first desulfurization tower 2, The first heat exchanger 3, the reforming converter (reforming conversion reactor) 4 and the gas-based shaft furnace 5, wherein:

[0059] The retort gas purifier 1 is provided with a retort gas inlet and a purified gas outlet; the retort gas purifier is used to purify the retort gas to remove dust and remove heavy hydrocarbons to obtain purified gas;

[0060] The first desulfurization tower 2 is provided with a purified gas inlet and a desulfurized gas outlet, and the purified gas inlet is connected to the purified gas outlet of the dry distillation gas purifier; Sulfur content below 10ppm;

[0061] The first heat exchanger 3 is provided with a desulfurization gas inlet and a heating gas outlet, and the desulfur...

Embodiment 2

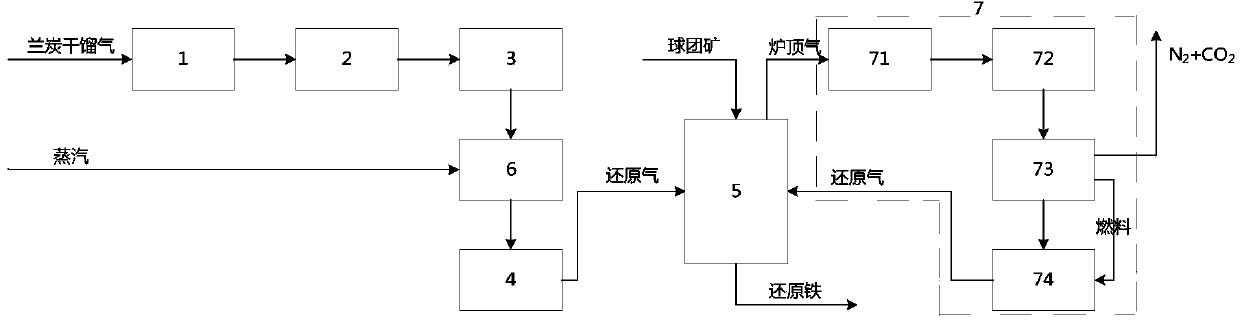

[0070] See figure 2 shown, with figure 1 Compared with the shown device, the device of the present invention for producing reduced iron by utilizing carbonized coal gas with high nitrogen content to produce reduced iron can further include a top gas purification system 7 of a gas-based shaft furnace (see figure 2 The part indicated by the dotted line in the middle), the top gas purification system 7 includes a scrubber 71, a second desulfurization tower 72, and a pressure swing adsorption tower 73 connected in series through pipelines; wherein:

[0071] The scrubber 71 is provided with a top gas inlet and a washed tail gas outlet, and the top gas inlet is connected with the top gas outlet of the gas-based shaft furnace 5; the scrubber is used to clean the top gas from the gas-based shaft furnace Perform washing (mainly dust removal) to obtain exhaust gas after washing;

[0072] The second desulfurization tower 72 is provided with a tail gas inlet after washing and an outle...

Embodiment 3

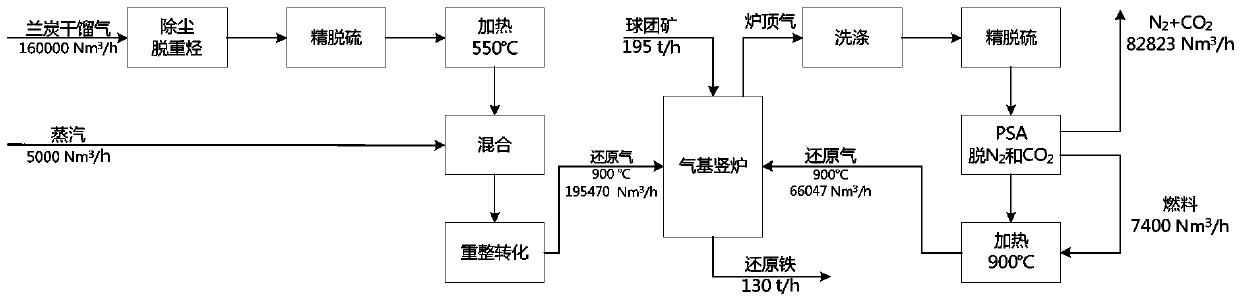

[0078] This embodiment provides a kind of nitrogen-containing about 39% semi-coke dry distillation gas supplemented with steam catalytic conversion combined with reduction tail gas pressure swing adsorption separation N 2 and CO 2 The method of producing DRI reduced iron, the reference of the equipment used figure 2 Shown, the process flow see image 3 shown.

[0079] Raw material blue carbon dry distillation gas 160000Nm 3 / h, of which hydrogen is about 31%, methane is about 8%, carbon monoxide is 10%, carbon dioxide is about 10%, nitrogen is about 39%, and a small amount of C 2 +, oxygen and saturated water components. The total sulfur content is less than 50mg / Nm 3 ; After the raw material is dedusted and de-heavy hydrocarbons, 70 tons of iron oxide at room temperature (produced by Shandong Dongying Kerte New Material Co., Ltd.) is used for desulfurization and purification, and the total sulfur content is reduced to about 1ppm. The gas is heated up to 550°C by heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com