Under-balanced drilling qi-stagnation slurry

An underbalanced drilling and slurry technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large drilling fluids, hidden dangers, weighted materials, etc., and achieve the effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

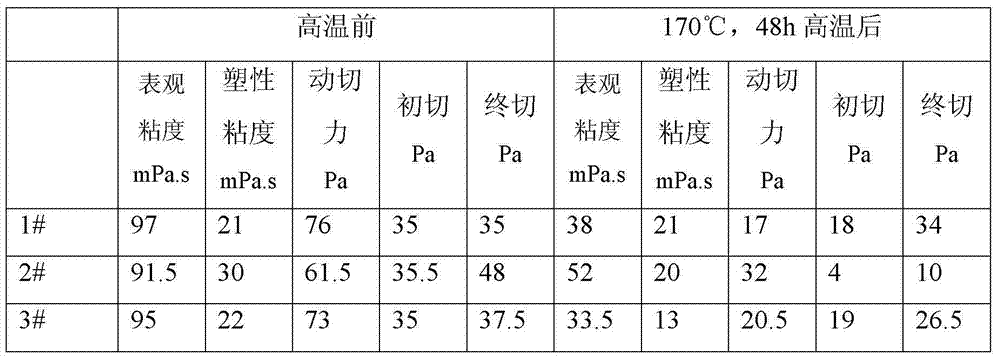

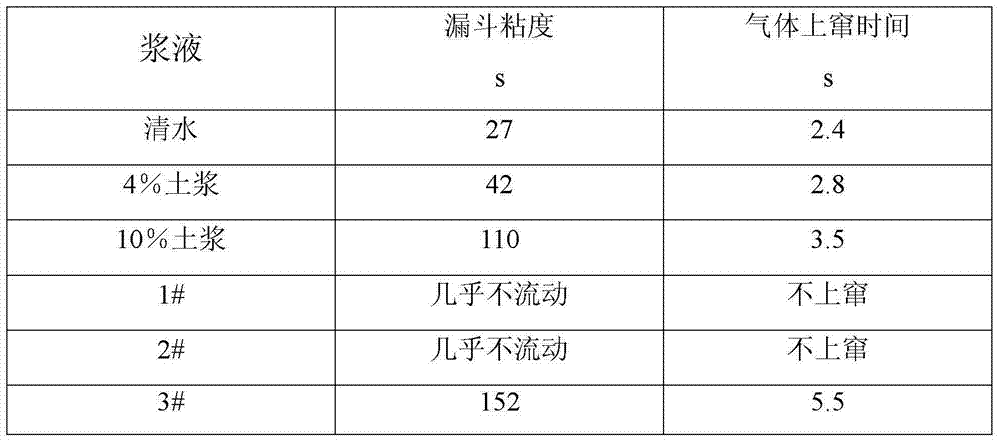

[0025] The preparation method of the air-slugging slurry for underbalanced drilling of the present invention will be described below in conjunction with specific examples.

[0026] In the following examples, the soil powder used is commercially available bentonite powder, and the soda ash (Na 2 CO 3 ) are commercially available. Other components adopted are also commercially available, and the trade marks of each component are as follows:

[0027] Potassium polyacrylate (tackifier): KPAM;

[0028] High viscosity xanthan gum (tackifier): XC-HV;

[0029] Positive gel dry powder (flow regulator): MMH

[0030] Low-viscosity xanthan gum (flow regulator): XC-LV;

[0031] Sulfonated phenolic resin (viscosifying fluid loss reducer): SMP-1;

[0032] For the convenience of description, in the following examples, the names of the components are replaced by the grades.

[0033] First, weigh each component by volume percentage:

[0034] 1#: water+0.6%XC-HV+0.4%XC-LV+1%SMP-1+8%soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com