Nano glass ceramic up-conversion luminescent material and preparation method thereof

A technology of luminescent materials and nano glass, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low chemical stability, uncontrollable crystal grains, poor mechanical strength, etc., achieve high mechanical strength, reduce interaction and crossover Excellent effect of relaxation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

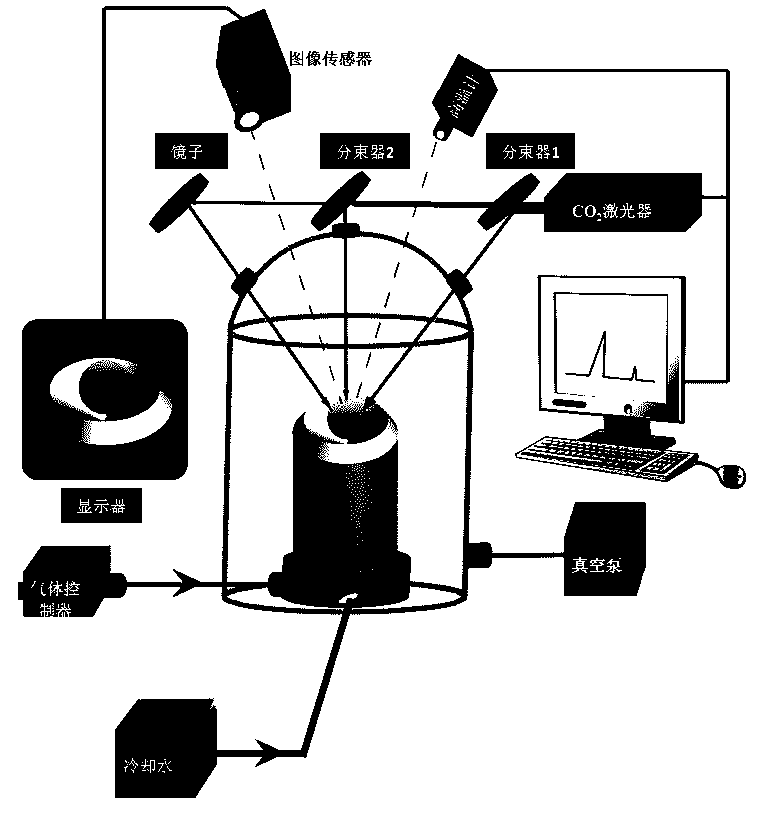

[0036] The preparation method of the nano-glass ceramic up-conversion luminescent material of the present invention includes: mixing the oxide powders constituting the up-conversion luminescent material, finely grinding, pre-sintering, granulating with polyvinyl alcohol solution, and then pressing into tablets, two First sintering, and then put into an air-suspension laser heating furnace for containerless melting to obtain an ellipsoidal or spherical precursor oxide glass; perform precise and controllable heat treatment on the precursor oxide glass to obtain a nano-glass ceramic up-conversion luminescent material. More specifically, as an example, the following steps may be used.

[0037] (1) Containerless solidification of precursor glass:

[0038] a) powder mixing: take by weighing each component oxide according to the weight ratio of nanometer glass-ceramic material, wherein matrix composition can be La 2 o 3 、TiO 2 , ZrO 2 , the doped luminescent component can be Nd ...

Embodiment 1

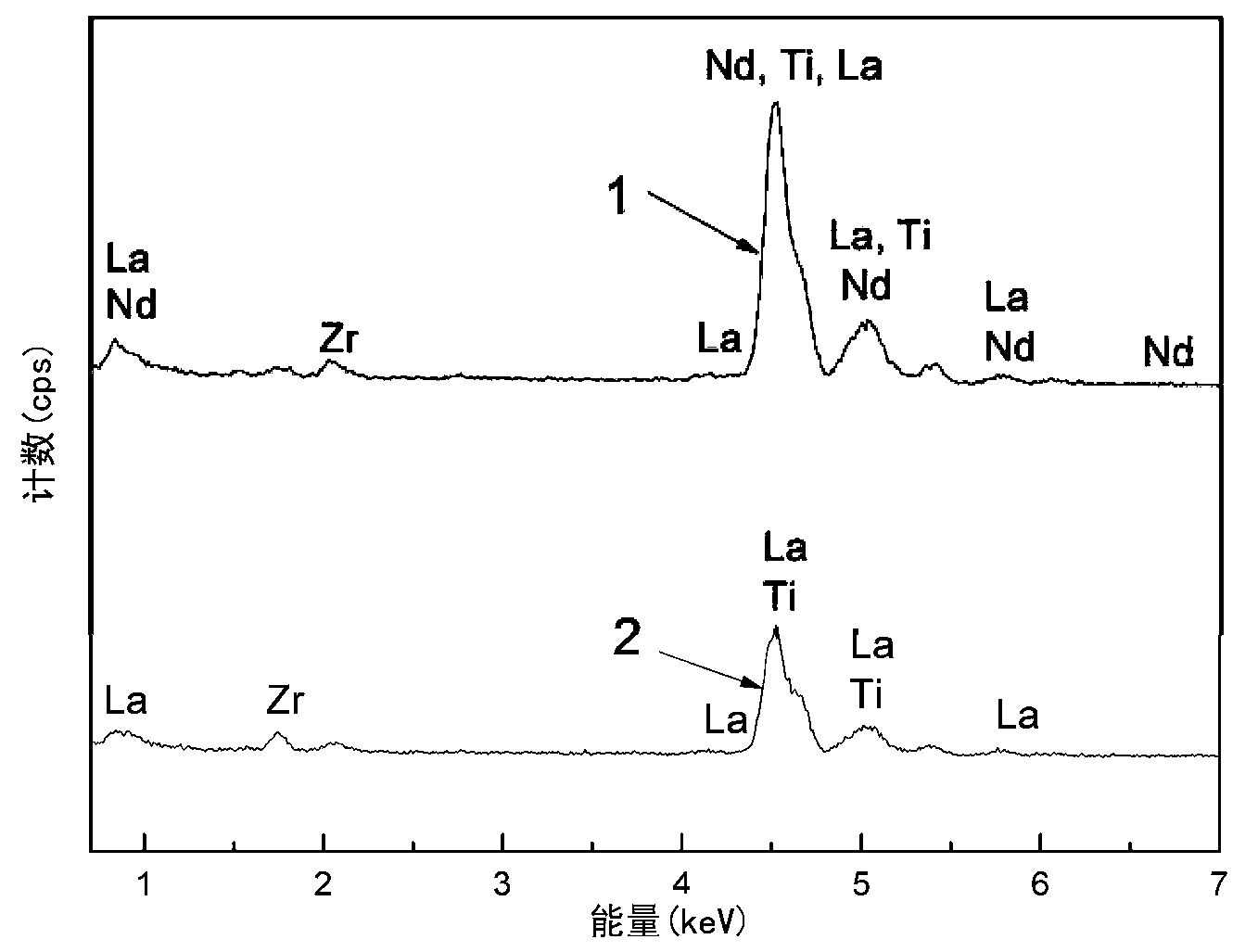

[0060] Embodiment 1, bulk nano glass ceramics (La 0.95 Nd 0.04 Yb 0.01 )(Ti 0.95 Zr 0.05 ) 2.25 o 6 Up-conversion luminescent material and its preparation:

[0061] The preparation process of bulk nano glass ceramics is as mentioned above. Before the containerless solidification of the precursor glass, the powder is pre-fired at 1000°C for 10 hours, the atmosphere is air, and the cooling is furnace cooling. When compressed, the weight of each tablet is about 75mg, and the pressure is about 10MPa. The pressed sheet was then kept at 1200°C for 8 hours. When there is no container for solidification, use a 1.5mm nozzle, and the laser power is about 65W. After the wafer is completely melted and uniform, keep it warm for 2-5 minutes, and suddenly turn off the laser to obtain a glass ball with a diameter of about 3mm. Polish the glass ball on both sides, the thickness after polishing is about 1.5mm, and then conduct precise and controllable heat treatment in the differential...

Embodiment 2

[0062] Embodiment 2, bulk nano glass ceramics (La 0.81 Nd 0.04 Yb 0.15 )(Ti 0.95 Zr 0.05 ) 2.25 o 6 Up-conversion luminescent material and its preparation:

[0063] The preparation process of bulk nano glass ceramics is as mentioned above. Before the containerless solidification of the precursor glass, the powder is pre-fired at 1000°C for 10 hours, the atmosphere is air, and the cooling is furnace cooling. When compressed, the weight of each tablet is about 75mg, and the pressure is about 10MPa. The pressed sheet was then kept at 1200°C for 8 hours. When there is no container for solidification, use a 1.5mm nozzle, and the laser power is about 65W. After the wafer is completely melted and uniform, keep it warm for 2-5 minutes, and suddenly turn off the laser to obtain a glass ball with a diameter of about 3mm. Polish the glass ball on both sides, the thickness after polishing is about 1.5mm, and then conduct precise and controllable heat treatment in the differential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com