Method for preparing ultra-low bulk density magnesium oxide

An ultra-low stack, magnesium oxide technology, applied in magnesium oxide and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

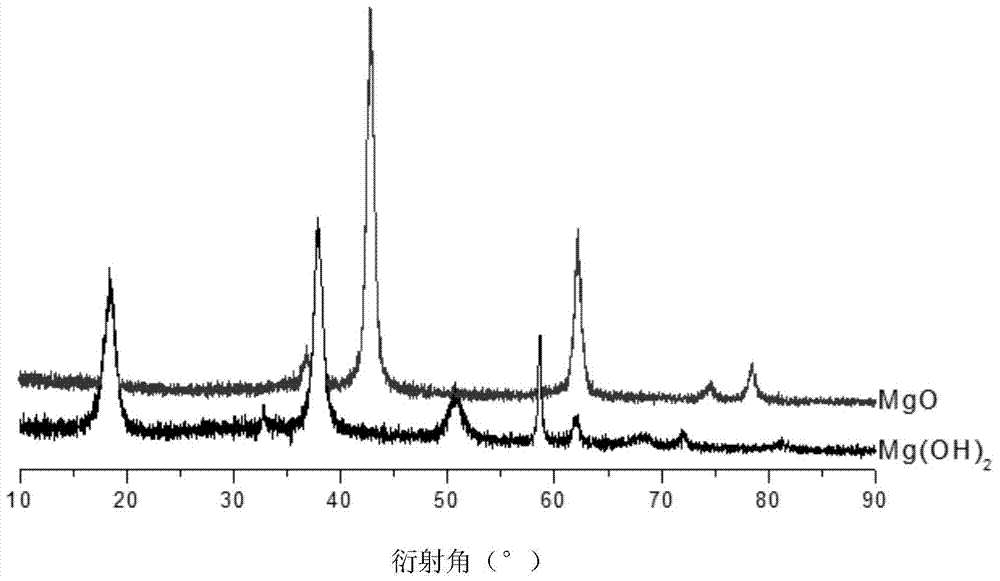

Embodiment 1

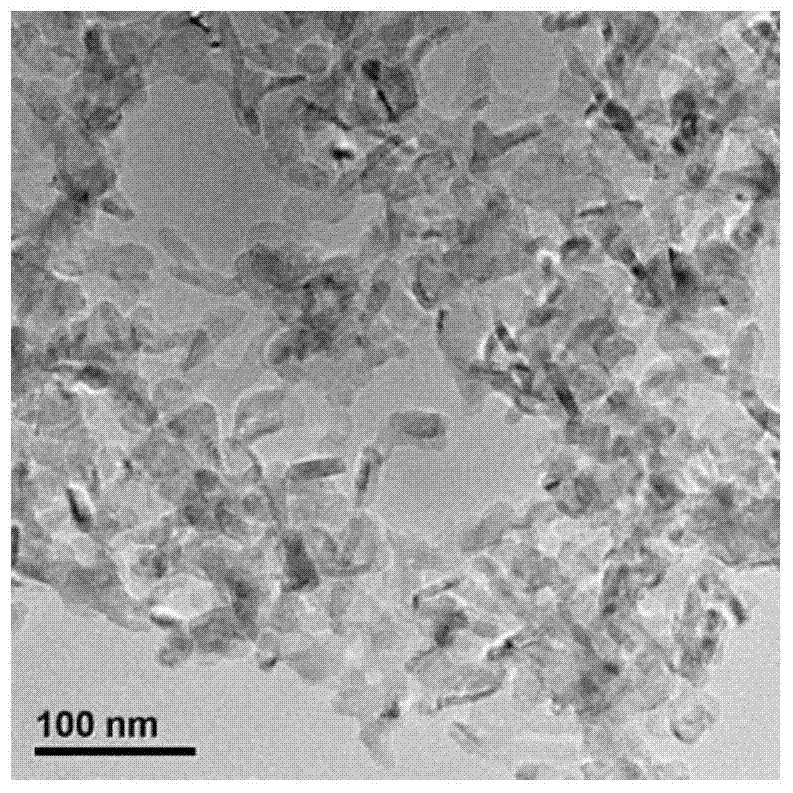

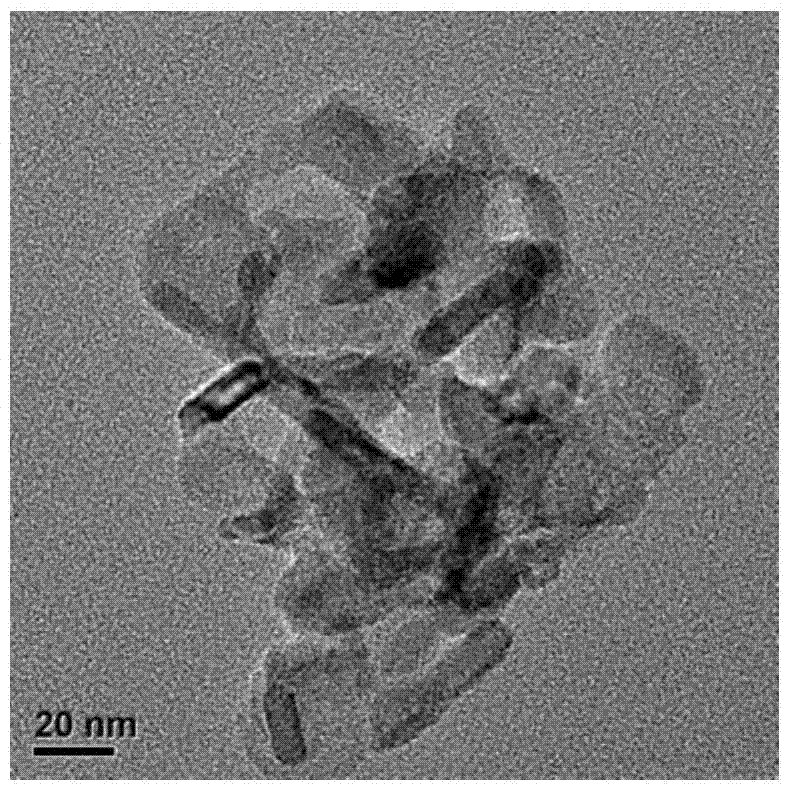

[0024] Prepare 0.5mol / L magnesium nitrate aqueous solution and 1mol / L sodium hydroxide solution. At room temperature, use a syringe pump to drop the magnesium nitrate solution into the sodium hydroxide solution at a speed of 50ml / h, and the stirring speed is 500r / min. Wash the obtained white precipitate with deionized water, centrifuge, wash the white precipitate obtained by centrifugation twice with ethanol, then add the ethanol homogenate of the obtained precipitate into a supercritical drying kettle, heat the kettle to 60°C, and then pass it into Supercritical carbon dioxide, maintain the pressure in the kettle at 15MPa, open the vent valve, and adjust the CO 2 Flow rate is 15L / h, runs 1h, takes out gained magnesium hydroxide white powder, and its bulk density is 0.0327g / ml. The resulting white powder was calcined to obtain magnesium oxide powder with a bulk density of 0.0342 g / ml.

Embodiment 2

[0026] Prepare 0.5mol / L magnesium nitrate aqueous solution and 1mol / L sodium hydroxide solution, take 50ml of sodium hydroxide solution and heat it to 100°C in a water bath, add the magnesium nitrate solution dropwise to the sodium hydroxide solution at a speed of 200ml / h with a syringe pump , the stirring speed is 500r / min, the white precipitate obtained is washed with deionized water, centrifuged, the white precipitate obtained by centrifugation is washed twice with ethanol, and then the ethanol homogenate of the obtained precipitate is added to a supercritical drying kettle, and the The kettle was heated to 60°C, and then supercritical carbon dioxide was introduced to maintain the pressure in the kettle at 15MPa, and the vent valve was opened to adjust the CO 2 Flow rate is 30L / h, runs 1h, takes out gained magnesium hydroxide white powder, and its bulk density is 0.0244g / ml. The resulting white powder was calcined to obtain magnesium oxide with a bulk density of 0.0284 g / ml...

Embodiment 3

[0028] Prepare a 1.0mol / L magnesium chloride aqueous solution and a 2.0mol / L sodium hydroxide solution, take 25ml of the sodium hydroxide solution and heat it in a water bath to 100°C, and add the magnesium nitrate solution dropwise to the sodium hydroxide solution at a rate of 400ml / h with a syringe pump , the stirring speed is 500r / min, the white precipitate obtained is washed with deionized water, centrifuged, the white precipitate obtained by centrifugation is washed twice with ethanol, and then the ethanol homogenate of the obtained precipitate is added to a supercritical drying kettle, and the The kettle was heated to 60°C, and then supercritical carbon dioxide was introduced to maintain the pressure in the kettle at 15MPa, and the vent valve was opened to adjust the CO 2 Flow rate is 30L / h, run 1.5h, take out the white powder of magnesium hydroxide obtained, and its bulk density is 0.0335g / ml. The resulting white powder was calcined to obtain magnesium oxide with a bulk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com