Preparation method for flake silver powder for electronic paste

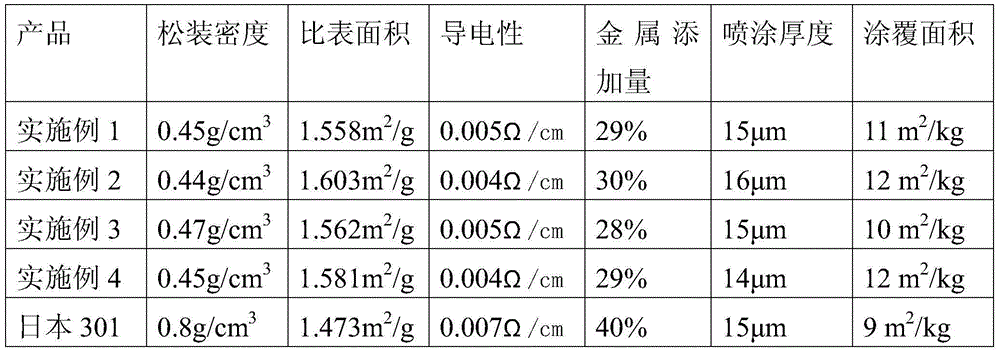

A technology of flaky silver powder and electronic paste, which is applied in the field of preparation of flaky silver powder for electronic paste, can solve the problems of high tap density, fast reaction speed, and poor sphericity of silver powder, and achieve large coating area, The effect of less filling amount and lower bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a, the preparation of silver powder: take the silver nitrate solution that mass percentage concentration is 25%, add the ascorbic acid solution that mass percentage concentration is 15% to react, when adding ascorbic acid solution, add slowly while stirring, and the time of adding is 15 minutes After the addition is completed, react at 20°C for 15 minutes, then filter to obtain spherical silver powder with uniform particle size; the weight ratio of the silver nitrate solution to the ascorbic acid solution is 1:1.25;

[0026] B, ball milling: according to the weight ratio of ball and spherical silver powder is the ratio of 30:1, described spherical silver powder is placed in ball mill, and ball adopts the ball that single diameter is 10mm to carry out; Then according to the amount of every kilogram of spherical silver powder, respectively Add 1L of ball milling medium, 20g of ball milling aid and 20mL of lubricant for ball milling, the time of ball milling is 6 hours, the...

Embodiment 2

[0032] a, the preparation of silver powder: take the silver nitrate solution that mass percentage concentration is 20%, add the ascorbic acid solution that mass percentage concentration is 20% to react, when adding ascorbic acid solution, add slowly while stirring, and the time of adding is 10 minutes , react under the condition of 25 ℃ for 20 minutes after the addition is completed, then filter to obtain spherical silver powder with uniform particle size; the weight ratio of the silver nitrate solution to the ascorbic acid solution is 1:1;

[0033] B, ball mill: according to the weight ratio of ball and spherical silver powder is the ratio of 10:1, described spherical silver powder is placed in the ball mill, and ball adopts the ball that single diameter is 20mm to carry out; Then press the amount of every kilogram of spherical silver powder, respectively Add 0.5L of ball milling medium, 30g of ball milling aid and 4mL of lubricant to carry out ball milling, the time of ball m...

Embodiment 3

[0039] a, the preparation of silver powder: take the silver nitrate solution that mass percentage concentration is 25%, add the ascorbic acid solution that mass percentage concentration is 20% to react, when adding ascorbic acid solution, add slowly while stirring, and the time of adding is 12 minutes After the addition is completed, react at 15°C for 10 minutes, then filter to obtain spherical silver powder with uniform particle size; the weight ratio of the silver nitrate solution to the ascorbic acid solution is 1:1.5;

[0040]B, ball milling: according to the weight ratio of ball and spherical silver powder is the ratio of 50:1, described spherical silver powder is placed in the ball mill, and the ball adopts the ball that single diameter is 4mm to carry out; Then according to the amount of every kilogram of spherical silver powder, respectively Add 2L of ball milling medium, 5g of ball milling aid and 40mL of lubricant for ball milling, the time of ball milling is 8 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com