Sulfur and arsenic adsorbent and preparation method thereof

A technology of adsorbent and binder, which is applied in the field of sulfur-arsenic adsorbent and its preparation, can solve the problems of low sulfur capacity and arsenic capacity, high bulk density of sulfur-arsenic adsorbent, etc., so as to increase the arsenic capacity and increase the chance of interface contact , Improve the effect of sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

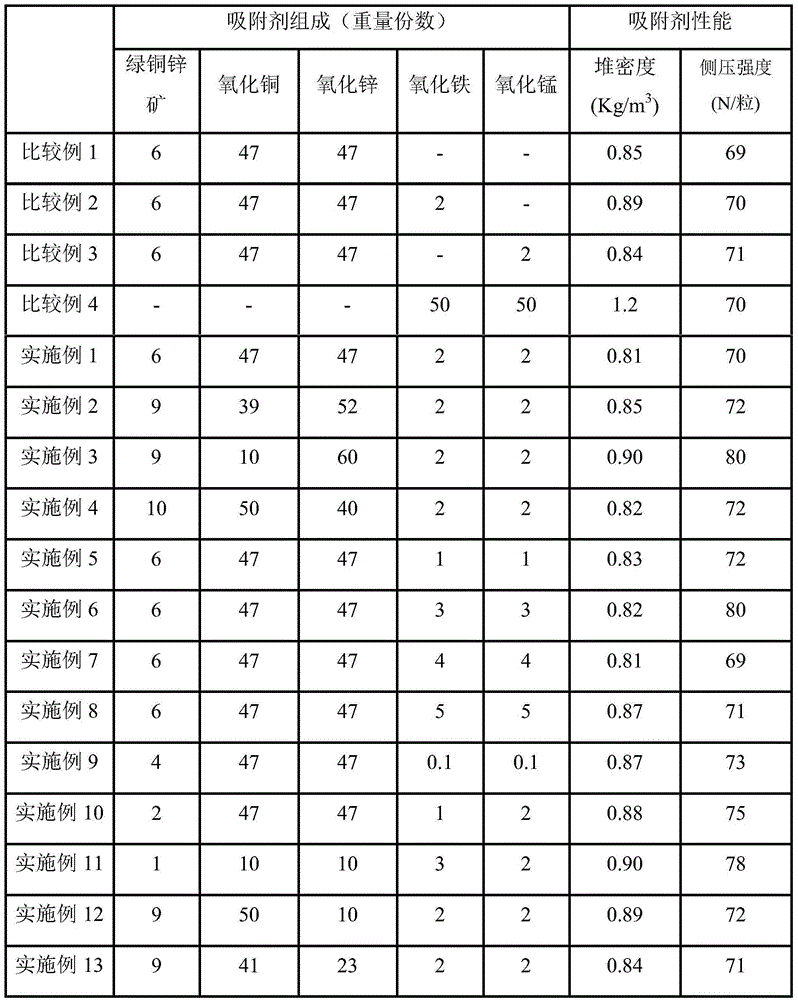

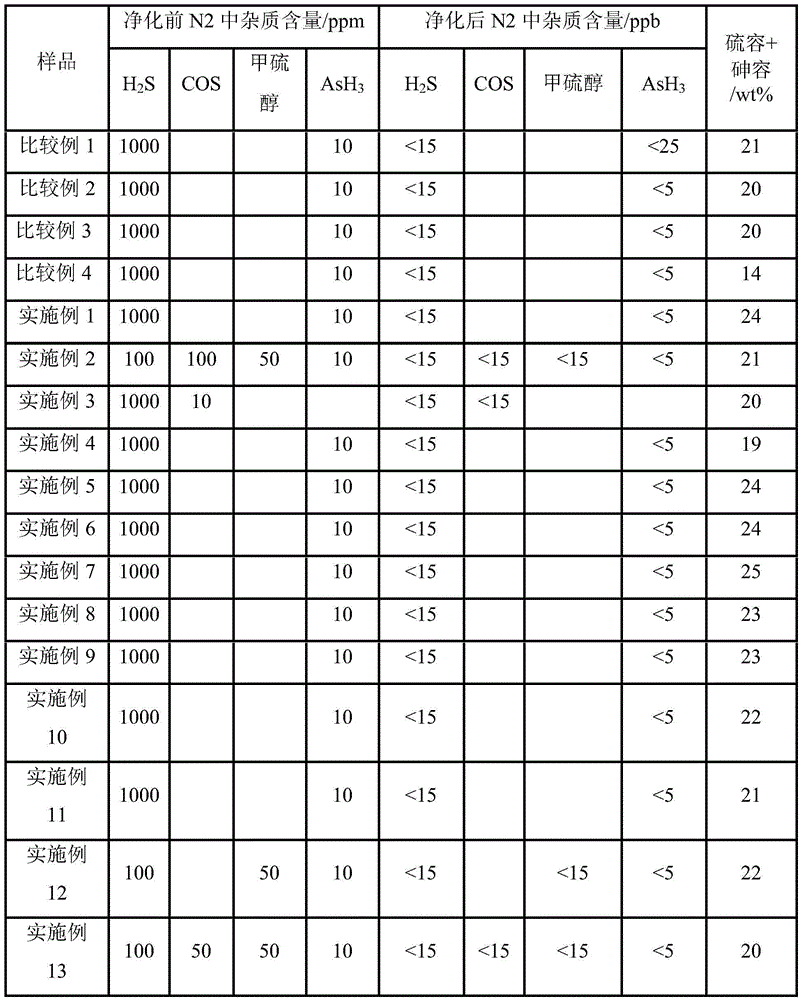

Embodiment 1

[0031] Mix 30 kilograms of copper nitrate, 40 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water and mix and stir evenly to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 70°C for 1 hour, wash and dry the precipitate, then add 6 kg of alumina, 1 kg of graphite, mix and roll, and then add 30% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

Embodiment 2

[0033] Mix 20 kilograms of copper nitrate, 50 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 60°C for 2 hours, wash and dry the precipitate, then add 5 kg of alumina, 1 kg of graphite, mix and roll, and then add 35% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

Embodiment 3

[0035]Mix 10 kilograms of copper nitrate, 60 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 60°C for 2 hours, wash and dry the precipitate, then add 6 kg of alumina, 1 kg of graphite, mix and roll, and then add 50% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com