Implantation fiber membrane used for pelvic floor dysfunction repair, preparation method and medical apparatus containing implantation fiber membrane used for pelvic floor dysfunction repair

A technology for implanting medical devices and dysfunction, applied in medical science, prosthesis, surgery, etc., can solve problems such as unsatisfactory performance of fiber membranes, and achieve favorable adhesion and proliferation, close fit, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

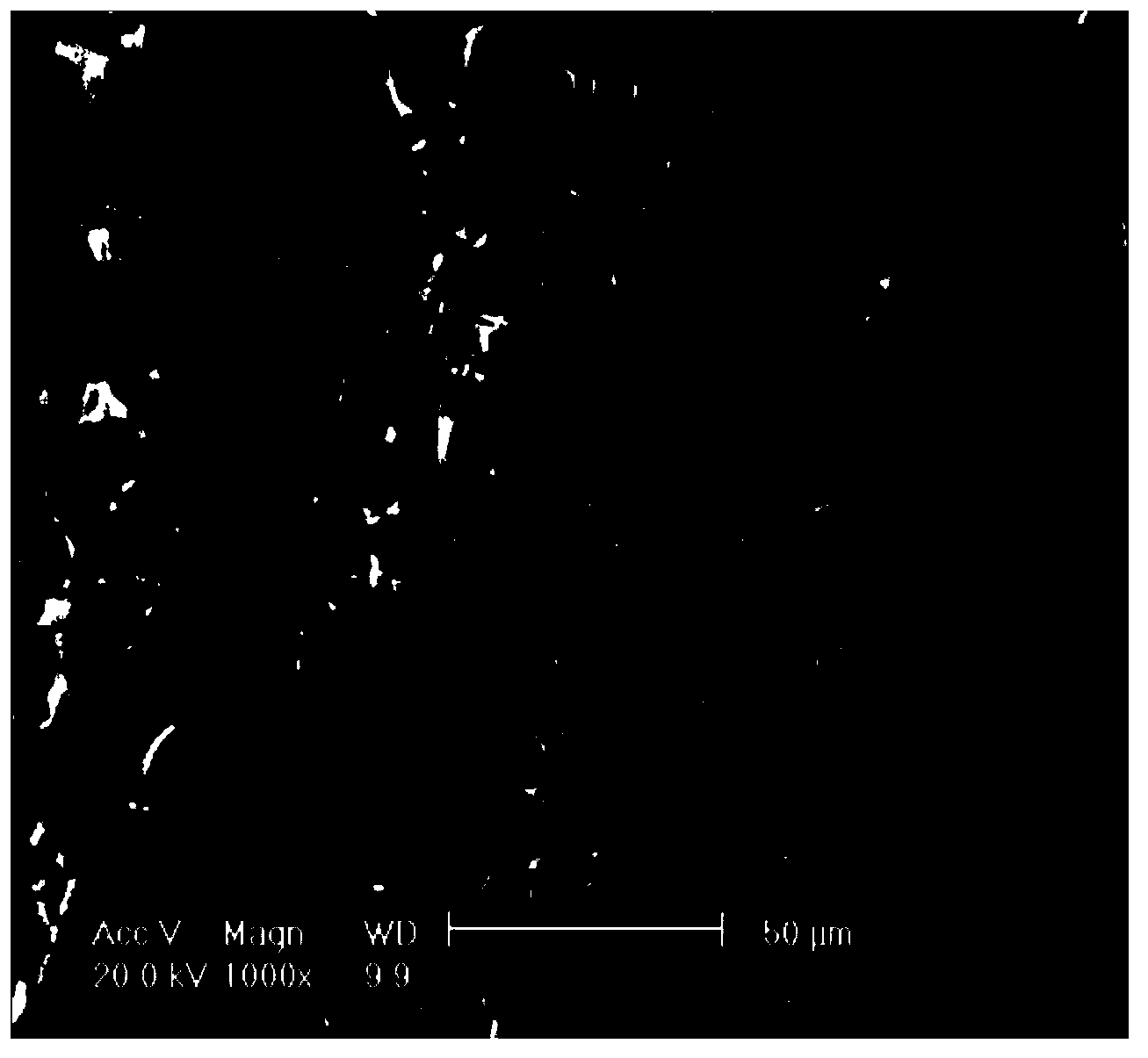

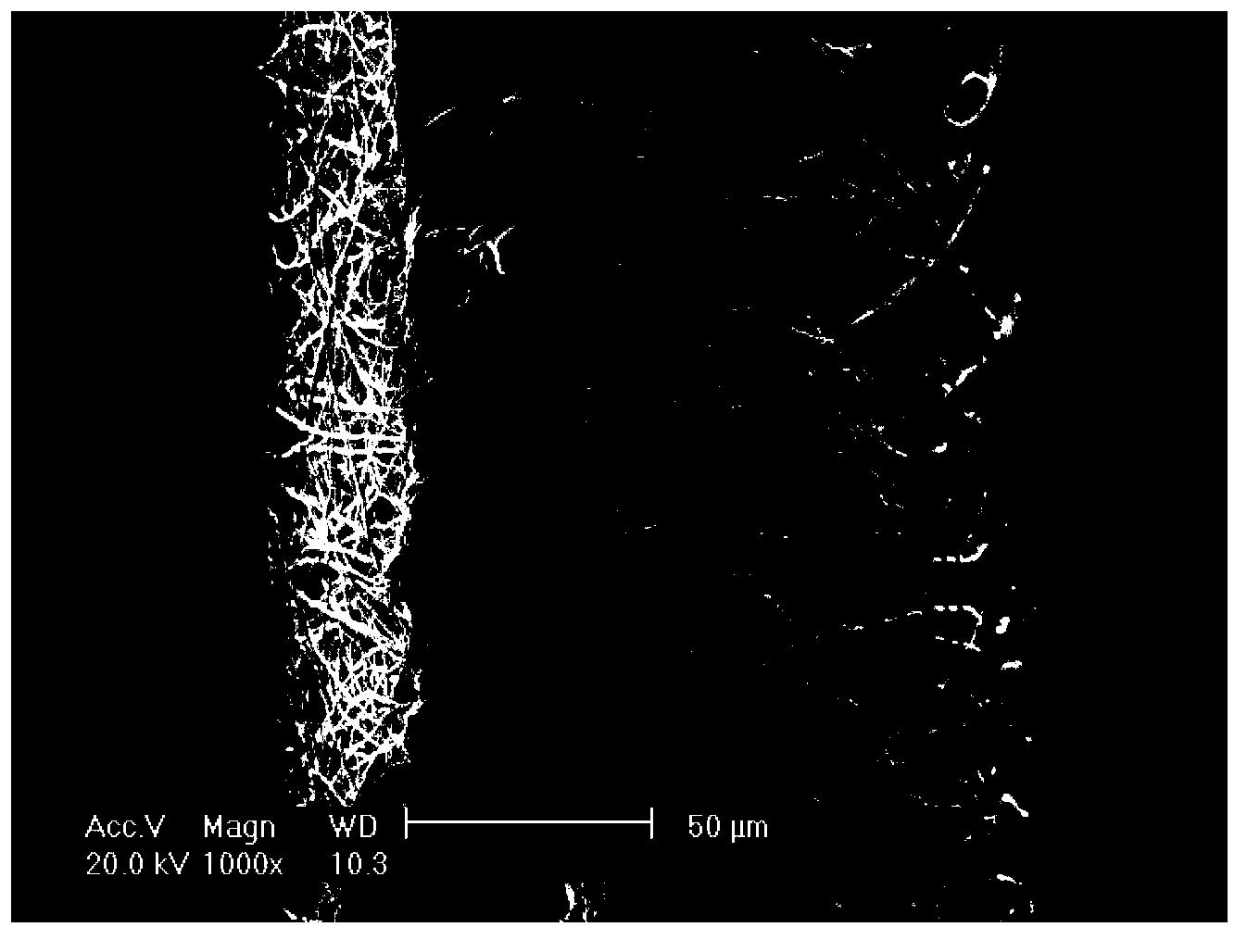

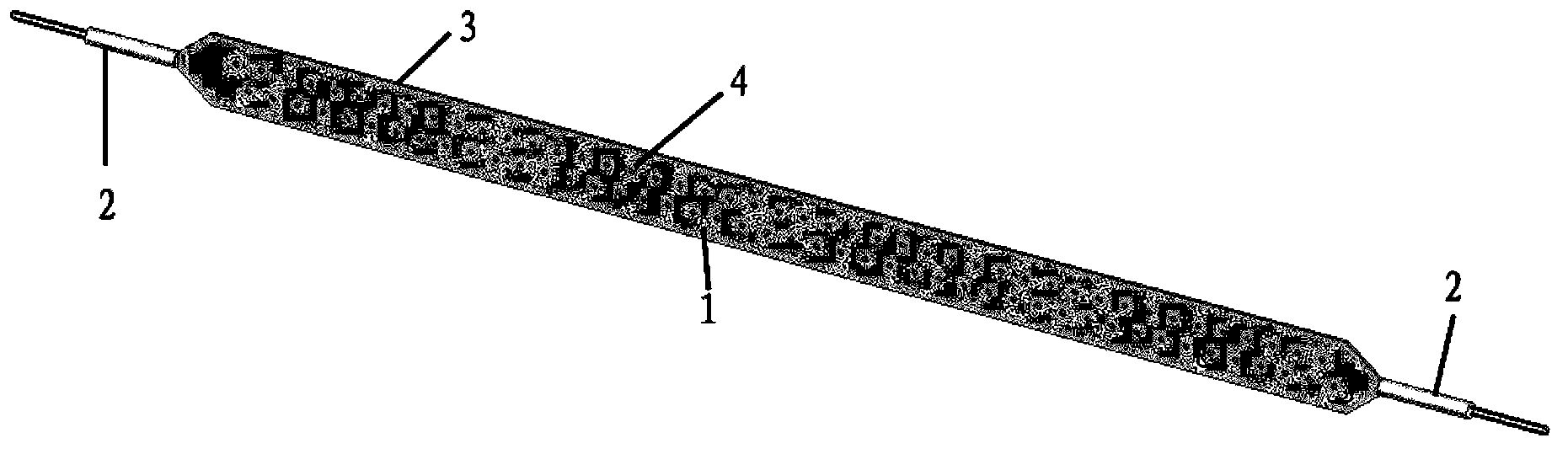

[0130] (1) Dissolve polyvinylidene fluoride (PVDF) in a mixed solvent of N,N-dimethylformamide / acetone with a volume ratio of 4:6, so that the concentration of PVDF in the solution is 18g / 100mL to obtain a uniform Fiber material solution A; L-polylactic acid (PLLA) was dissolved in hexafluoroisopropanol (HFIP) solution, so that the concentration of PLLA in the solution was 5g / 100mL, and a uniform fiber material solution B was obtained.

[0131] (2) The above two homogeneous fiber material solutions A and B were filled into five electrospinning syringes respectively, among which 4 syringes were filled with PVDF solution and one syringe was filled with PLLA solution. 4 injection needles corresponding to PVDF solution and 1 injection needle corresponding to PLLA are evenly arranged on the high-voltage power supply board, adjust the rate of the micro-injection pump to 5mL / hour, adjust the voltage of the high-voltage generator to 30KV, and adjust the receiving distance of the receiv...

Embodiment 2

[0135] (1) Dissolve PVDF material in N,N-dimethylformamide / acetone mixed solvent with a volume ratio of 4:6, so that the concentration of PVDF in the solution is 20g / 100mL; prepare a uniform fiber material solution.

[0136] (2) Put the fiber material solution obtained in step (1) into the electrospinning syringe, adjust the rate of the micro-injection pump to 6mL / hour, adjust the voltage of the high-voltage generator to 30KV, and adjust the receiving distance of the receiving device to 25cm , electrospinning is carried out to obtain fiber filaments, and the fiber filaments are received into a film-like structure, and the electrospinning is stopped after spinning until the thickness of the film layer is about 0.5 mm to obtain a fiber film.

[0137] The fiber membrane obtained here has an average fiber diameter of 2 μm, a membrane thickness of 0.5 mm, an average pore diameter of 150 μm, a tensile strength of 32 N / cm, and a bulkiness of 110 cm 3 / g, the softness is 740 millinewt...

Embodiment 3

[0141] (1) Dissolve PVDF material in N,N-dimethylformamide / acetone mixed solvent with a volume ratio of 4:6, so that the concentration of PVDF in the solution is 18g / 100mL; prepare a uniform fiber material solution;

[0142] (2) Put the fiber material solution obtained in step (1) into the electrospinning syringe, adjust the rate of the micro-injection pump to 6mL / hour, adjust the voltage of the high-voltage generator to 30KV, and adjust the receiving distance of the receiving device to 20cm , electrospinning is carried out to obtain fiber filaments, and the fiber filaments are received into a film-like structure, and the electrospinning is stopped after spinning until the thickness of the film layer is about 0.5 mm to obtain a fiber film.

[0143] The fiber membrane obtained here has an average fiber diameter of 2 μm, a membrane thickness of 0.5 mm, an average pore diameter of 190 μm, a tensile strength of 43 N / cm, and a bulkiness of 170 cm 3 / g, the softness is 930 millinewt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Loft | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com