Capacitor-used electrolyte, preparation method thereof and asymmetric electrochemical capacitor

An electrolyte and capacitor technology, applied in the field of capacitors, can solve problems such as poor cycle performance, and achieve the effects of small discharge specific capacity, good cycle performance, and increased specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a preparation method of an electrolyte for a capacitor, comprising the following steps:

[0043] a) Reaction of alkyl halide and triethylamine in an organic solvent to obtain alkyl-substituted tetraethylammonium halide, the alkyl halide is monohaloalkane or dihaloalkane, and the number of carbon atoms of the alkyl group in the haloalkane is 3 to 10 ;

[0044] b) mixing the alkyl-substituted tetraethylammonium halide obtained in step a) with silver oxide, and reacting to obtain alkyl-substituted tetraethylammonium hydroxide;

[0045] c) react the alkyl-substituted tetraethylammonium hydroxide obtained in step b) with fluoroboric acid to obtain alkyl-substituted tetraethylammonium tetrafluoroborate, and the alkyl replaces the tetraethylammonium in the tetraethyl One, the alkyl group is connected to N.

[0046] The present invention uses haloalkane and triethylamine as raw materials, first synthesizes alkyl-substituted tetraethylammonium halide, then...

Embodiment 1~3

[0067]Add 0.05 mol of n-propane iodide, isopropane iodide and n-butane iodide, 0.05 mol of triethylamine and 10 mL of acetonitrile into a round-bottomed flask, and heat to reflux at 95°C for 24 hours in an oil bath. The obtained reaction product was distilled off under reduced pressure to remove the solvent to obtain an orange solid. Then, ethyl acetate was used for three times of recrystallization, and the obtained crystalline product was dried in an oven at 50° C. to obtain a light yellow solid, which was alkyl-substituted tetraethylammonium iodide. The obtained pale yellow solid was dissolved in water, and then an excess of silver oxide was added thereto to remove iodide ions in the solution. The obtained mixed solution was filtered, and the pH value of the filtrate was adjusted to neutral with 40% fluoroboric acid aqueous solution, and then the water therein was distilled off under reduced pressure to obtain a crude product of quaternary ammonium salt. The crude product w...

Embodiment 4

[0077] 16g of 1,4-dibromobutane, 46mL of acetonitrile and 30g of triethylamine were successively added into the round-bottomed flask, which was heated to reflux at 90°C in an oil bath for 24h. The obtained reaction product was evaporated to dryness at 90° C., and then recrystallized with ethanol to obtain a powdery white solid. The white solid is dissolved in water, and then sufficient silver oxide is added thereto to remove bromide ions in the product. The obtained mixed solution was filtered, and the pH value of the filtrate was adjusted to neutral with 40% fluoroboric acid aqueous solution of the alkali filtrate, and then the water was removed by distillation under reduced pressure to obtain a crude product of quaternary ammonium salt. The crude product was recrystallized three times with ethanol to obtain pure quaternary ammonium salt.

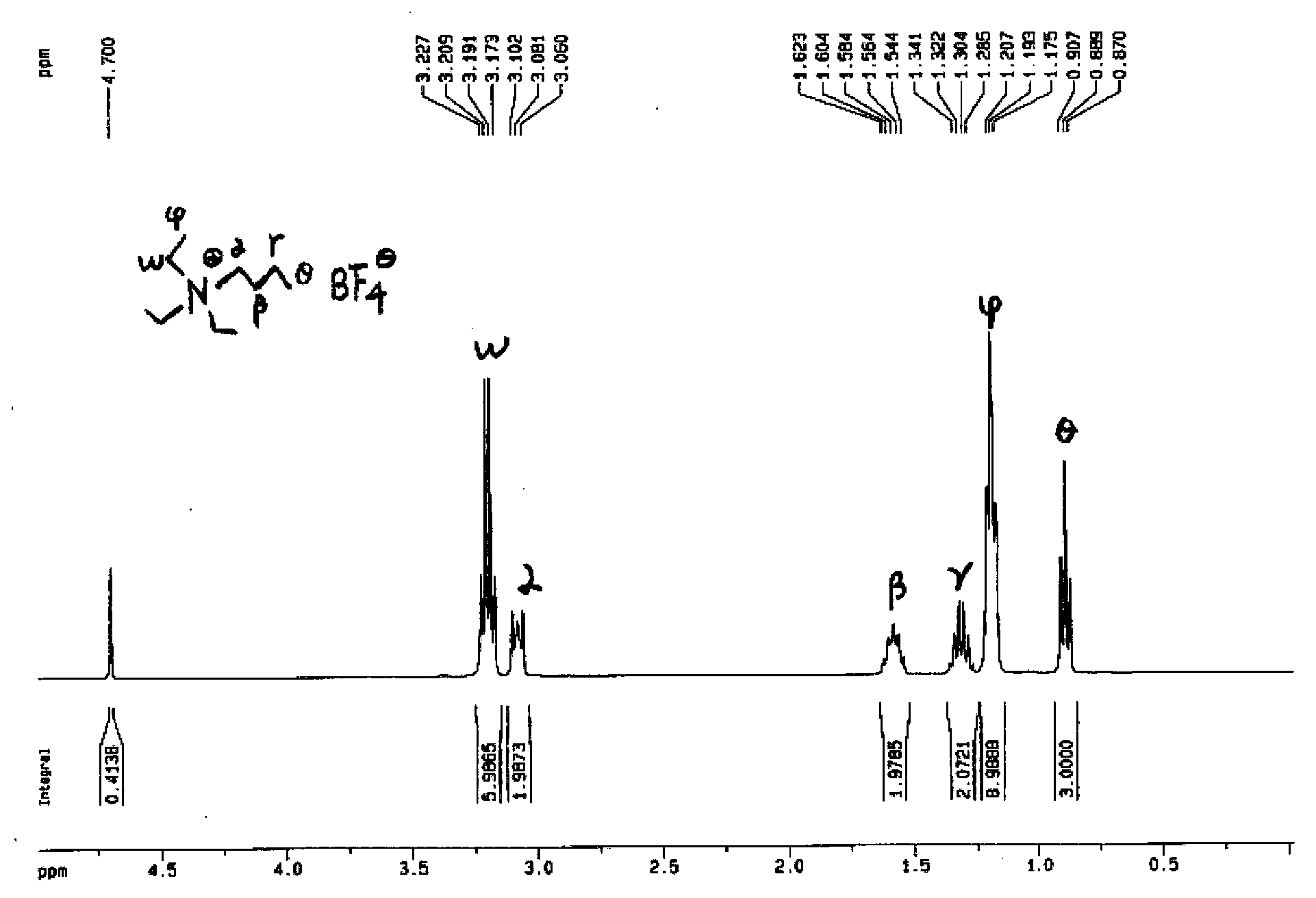

[0078] The product that the present invention will obtain carries out nuclear magnetic resonance detection with nuclear magnetic resonan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com