A Spatial Calibration Body Based on Virtual Ball and Its Calibration Method

A calibration method and virtual ball technology, which are applied to the space calibration body based on the virtual ball and its calibration field, can solve the problems of affecting the accuracy of calibration results, high processing costs, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

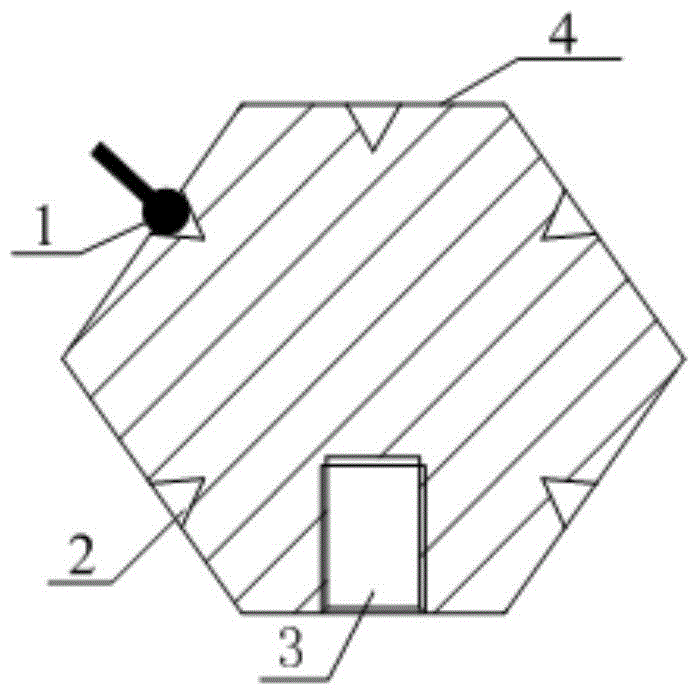

[0042] Referring to the accompanying drawings, a space calibration body based on a virtual sphere and its calibration method, the regular octahedron 4 with the top cut off is selected as the main body of the virtual ball, and a cone socket 2 is processed on each surface, and a surface with a top cut off A taper socket 2 is machined at the center, and an M6×10 threaded hole is machined at the center of the other top surface. During the specific implementation process, the taper angle is set to 60-120°; the purpose of the taper socket 2 is to locate the joint to be marked The probe 1 of the type coordinate measuring machine must ensure that each cone dimple must have a good conicity;

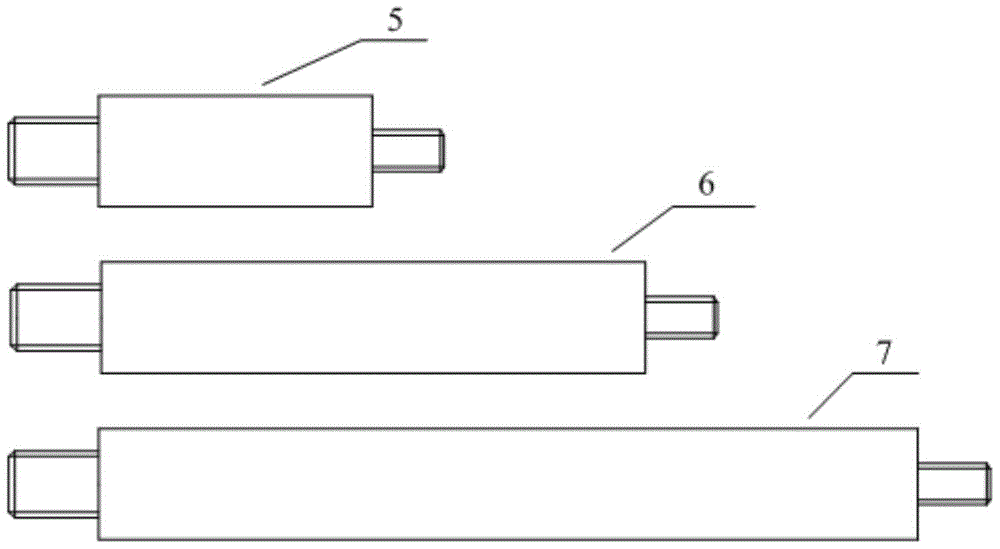

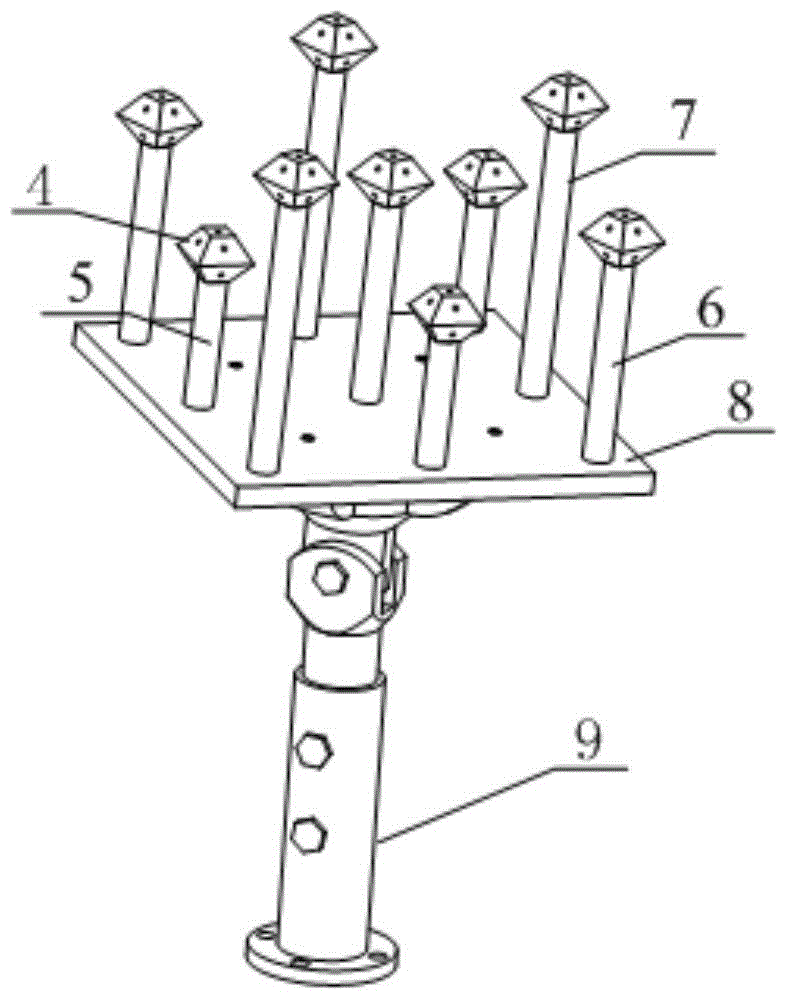

[0043] First, the regular octahedron 4 with the cut top and the standard rods 5, 6, and 7 are fixedly connected with threads respectively, and secondly, refer to image 3 , according to the corresponding positions, the standard rods 5, 6, 7 are fixed to the hard aluminum alloy plate 8 through thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com