Automobile noise reduction system with one-fourth wavelength pipes combined with Helmholtz silencer

A noise reduction system and wavelength tube technology, applied in the field of automotive noise reduction systems, can solve the problems of poor fuel economy, high power consumption, and high manufacturing costs, and achieve low manufacturing costs, low power consumption, and improved environmental quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

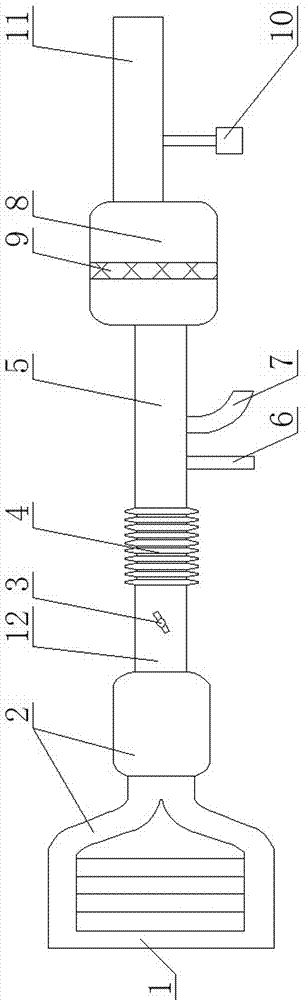

[0037] Specific implementation method one: such as figure 1 As well as figure 2 and Figure 4 It shows that the car noise reduction system of the 1 / 4 wavelength tube combined with the Himshitz muffler, including intake manifolds 1. Inlet pipe 2. Erspeare door 3. Flexible connecting pipe 4. Air filter 8. Air filtering mesh, air filters9. Ahead of the air pipe 11. Humhoz's muffler 10, two rear intake ducts and two 1 / 4 wavelength pipes.Qi Guidance 2:12, the two 1 / 4 wavelength tubes of 1 / 4 wavelength tube 1 / 4 wavelength tube 1 / 4 and 1 / 4 wavelength pipe 2 7, the Humhhitz muffler 10 end and the forward gas pipe 11 sideThe wall connection and connecting the front air pipe 11, the forward gas pipe 11 out of the air and the air filter 8 inlet end, the air filter 9, the air filter 8 out of the air end andRear intake catheter 1 5 intake terminal is connected, rear intake duct 1 5 out of the air intake pipe 4 with the backward air catheter 2 12 inlet terminal, rear intake pipe 2 12 has throttl...

specific Embodiment approach 2

[0040] Specific implementation method two: such as figure 1 and Figure 4 The 1 / 4 wavelength tube of the specific embodiment of the specific embodiment combined with the car noise reduction system of the Homhoz muffler, the 1 / 4 wavelength tube 1 6 is the direct tube, and the 1 / 4 wavelength tube 2 7 is the curvedTube.The volume (transmission loss) of the 1 / 4 wavelength tube is related to the length and wavelength of the pipeline.The direct tube (that is, 1 / 4 wavelength tube 1 6) is shorter than the bending tube (1 / 4 wavelength tube 27), and the sound emissions effect is worse.The reason is that when the air enters the pipeline, the two tubes are restricted by each other, and the vortex gradually forms in the tube, which consumes a lot of sound energy.

specific Embodiment approach 3

[0041] Specific implementation method three: such as figure 1 and Figure 4 Show, the car noise reduction system of the 1 / 4 wavelength tube of the specific implementation method and the two wavelength pipes in charge of Humhhitz's muffler, the internal cavity diameter of the front cavity of the front air canal is 7.2-7.6cm.The length is 10-27cm.

[0042] The invention calculates the inherent frequency of the resonance cavity and the 1 / 4 wavelength tube, and then calculates the loss of the resonant cavity, that is, the volume of the sound, and finally determine the geometric size of the resonant cavity.

[0043] The present invention introduces the air into the combustion room through intake manifold 1. In this way, the Humhz Scholarship 10 is connected to the engine, because the system of the present invention is a co -accent mucoper and two 1 / 4 wavelength pipes.There is a small hole one on the side wall of the front air pipe 11. The small hole one is connected with the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com