A light-weight composite sound insulation board for ships and its manufacturing method

A manufacturing method and lightweight technology, applied in the field of noise control in ship cabins, can solve the problems of high density of rock wool, fire performance that cannot meet the requirements of marine B15 grade, and can not meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

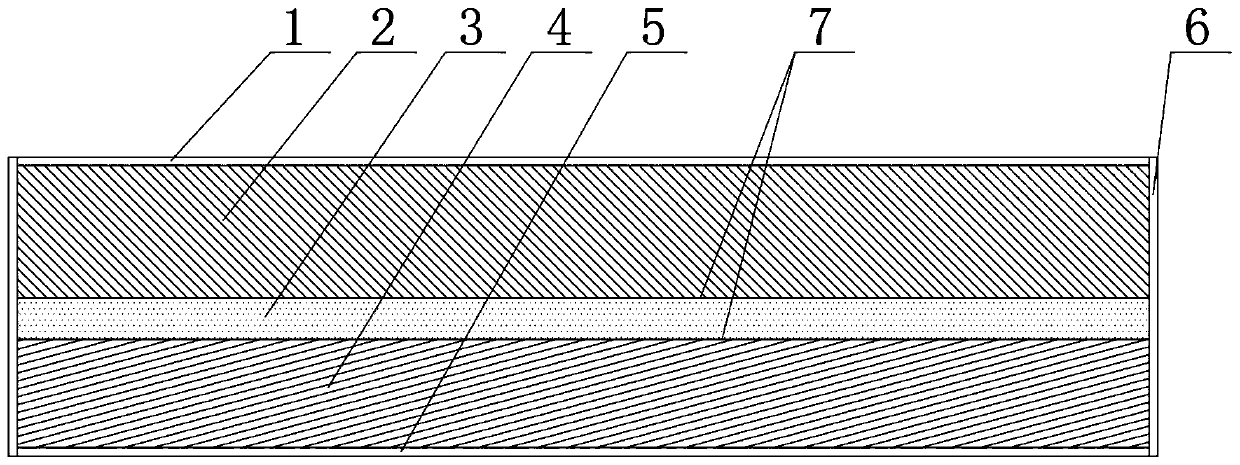

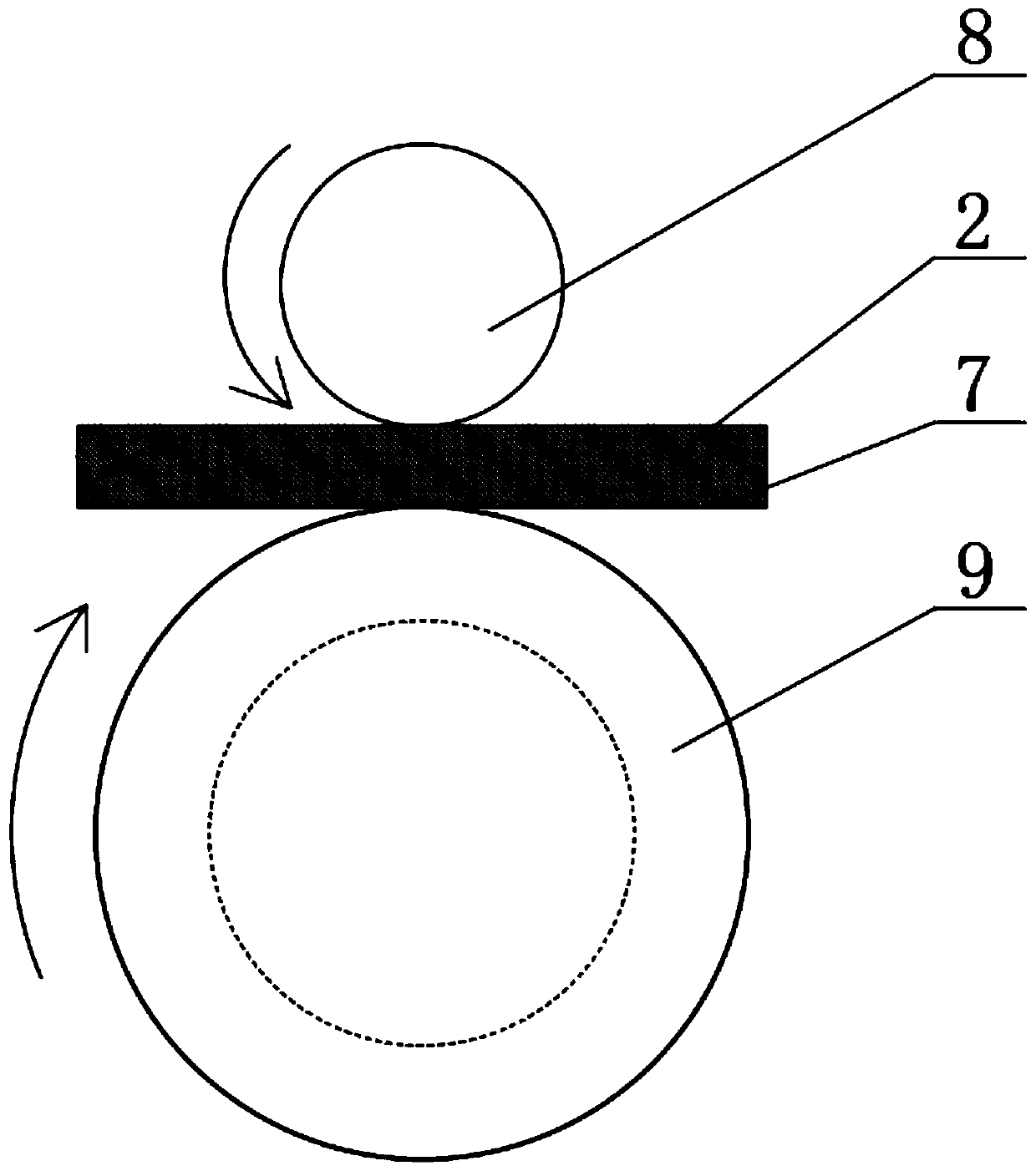

[0051] Such as figure 1 As shown, the marine lightweight composite sound insulation board of this embodiment includes a lower panel 5 located below, a rock wool layer 4 is arranged on the upper part of the lower panel 5, and a mesh glass fiber cloth 7 is arranged on the top surface of the rock wool layer 4 ; Also comprise the upper panel 1 positioned at the top, the upper panel 1 is parallel to the lower panel 5, the bottom surface of the upper panel 1 is provided with a glass wool layer 2, the bottom surface of the glass wool layer 2 is provided with a reticular glass fiber cloth 7, and the rock wool layer 4 The reticulated glass fiber cloth 7 and the reticulated glass fiber cloth 7 of the glass wool layer 2 are arranged at a distance, an air layer 3 is formed at this interval, and side panels 6 are respectively welded on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com