Epoxy-based carbon fiber sizing agent emulsion, its preparation method and its application

An epoxy-based carbon fiber and emulsion technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve problems such as failure to meet the application requirements of final composite materials, decreased stability of sizing agent emulsion, loss of elasticity and wear resistance, etc. Achieve the effects of stable industrial production, good application stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

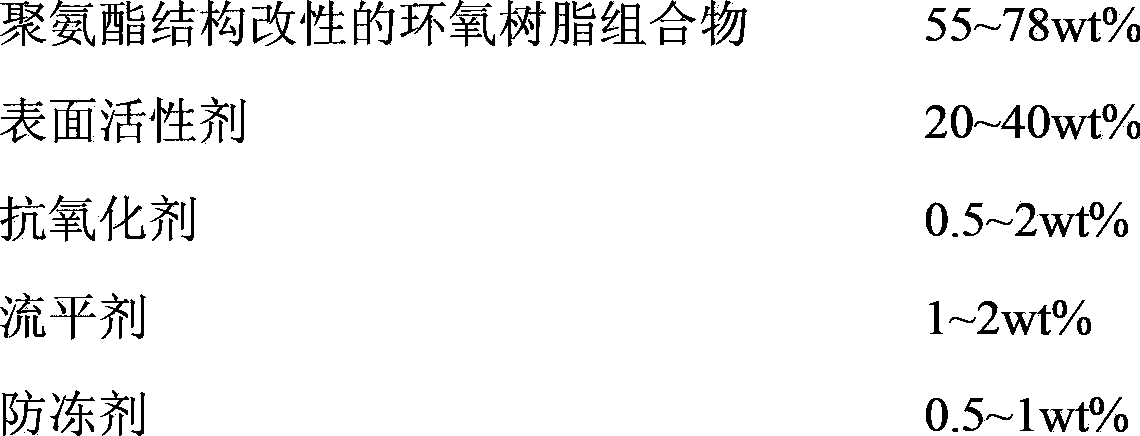

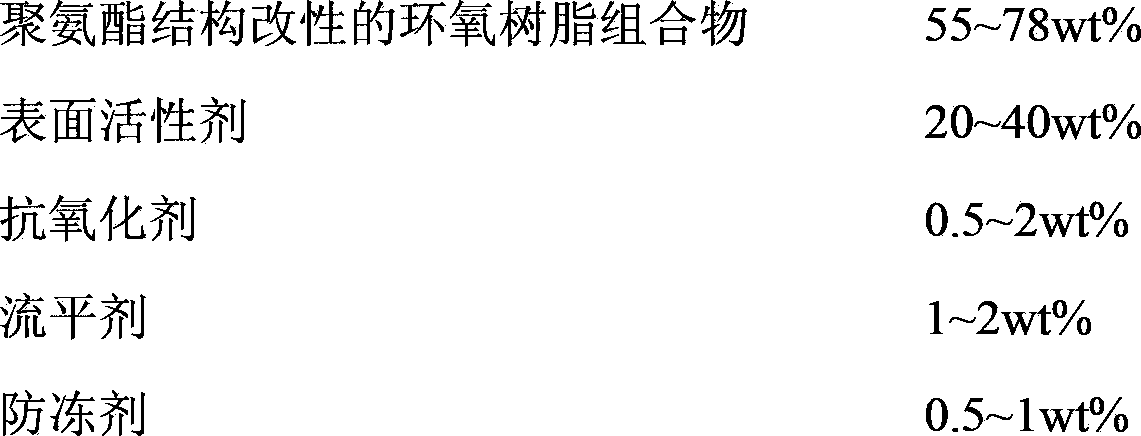

[0042] One, the preparation of the epoxy resin composition of polyurethane modification

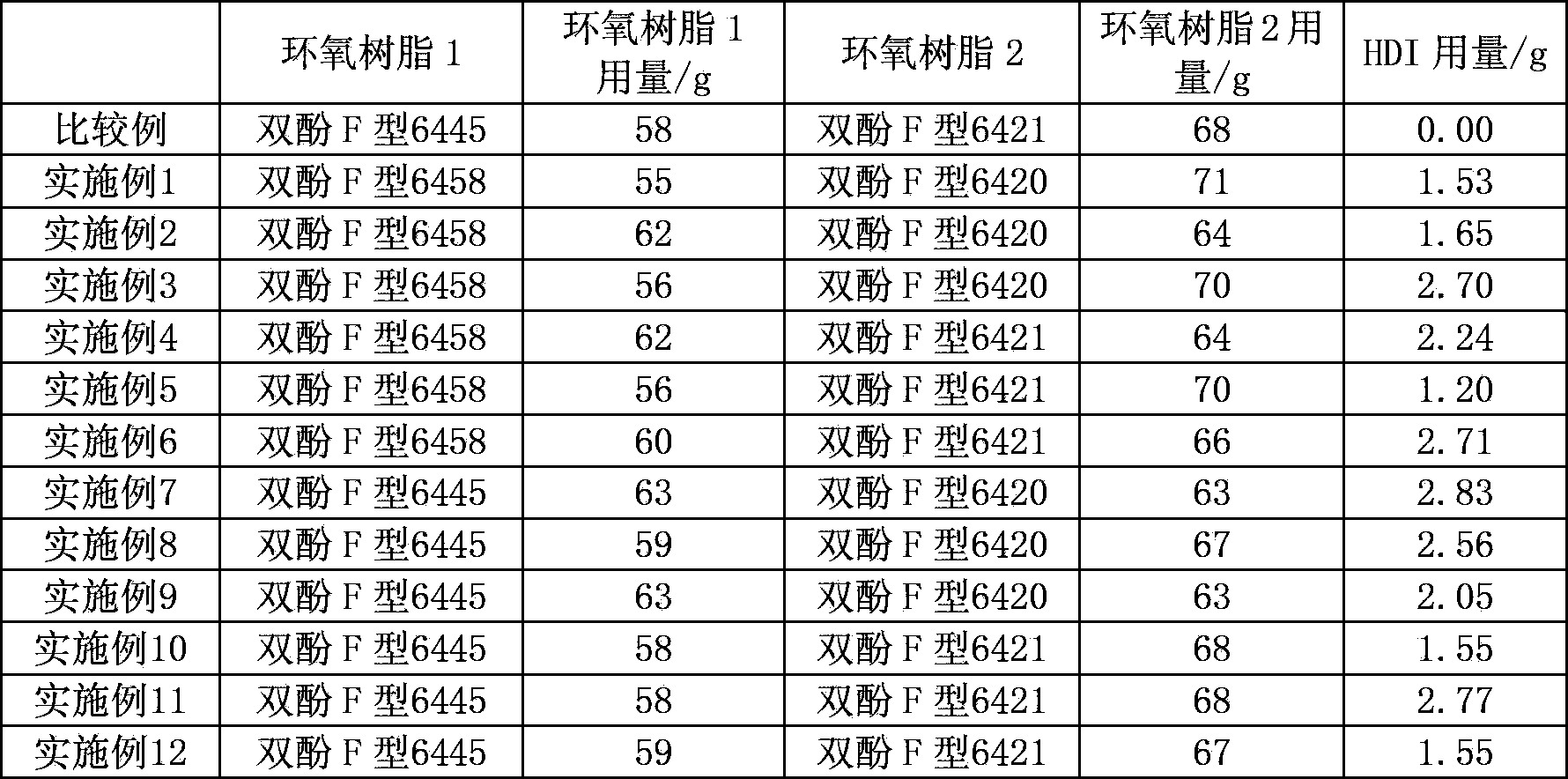

[0043] Put the quantitative epoxy resin mixture in a 250ml four-neck flask with a mechanical stirring device, heat to 110°C, control the vacuum pressure at 100-0.1mmHg, and vacuum dehydrate for 2 hours until no bubbles are generated. Cool down to 70°C, remove the vacuum device, and insert a condenser tube. Under the protection of high-purity nitrogen, a quantitative amount of hexamethylene diisocyanate (HDI) was slowly added dropwise into the flask with a micro metering pump. After the dropwise addition, it was reacted at 70°C for 1 hour, and then the temperature was raised to 95°C. ℃ for more than 2 hours, sampling for infrared analysis, when the results show that there is no -NCO group, the polyurethane structure modified epoxy resin composition is prepared. The type and amount of epoxy resin mixture used, and the amount of hexamethylene diisocyanate (HDI) are shown in Table 1.

[004...

Embodiment 13-24

[0059] One, the preparation of the epoxy resin composition of polyurethane modification

[0060] Put the quantitative epoxy resin mixture in a 250ml four-neck flask with a mechanical stirring device, heat to 110°C, control the vacuum pressure at 100-0.1mmHg, and vacuum dehydrate for 2 hours until no bubbles are generated. Cool down to 70°C, remove the vacuum device, and insert a condenser tube. Under the protection of high-purity nitrogen, a quantitative amount of isophorone diisocyanate (IPDI) was slowly added dropwise to the flask with a micro metering pump. After the dropwise addition, it was reacted at 70°C for 1 hour, and then heated to 95°C After reacting for more than 2 hours, a sample was taken for infrared analysis, and when the result showed no -NCO group, a polyurethane structure-modified epoxy resin composition was obtained. The type and amount of epoxy resin mixture used, and the amount of isophorone diisocyanate (IPDI) are shown in Table 4.

[0061] Table 4, ra...

Embodiment 25-36

[0076] One, the preparation of the epoxy resin composition of polyurethane modification

[0077] Put the quantitative epoxy resin mixture in a 250ml four-neck flask with a mechanical stirring device, heat to 110°C, control the vacuum pressure at 100-0.1mmHg, and vacuum dehydrate for 2 hours until no bubbles are generated. Cool down to 50°C, remove the vacuum device, and insert a condenser tube. Under the protection of high-purity nitrogen, a quantitative amount of diphenylmethane diisocyanate (MDI) was slowly added dropwise into the flask with a micrometering pump. After the dropwise addition, it was reacted at 50°C for 1 hour, and then heated to 85°C. After reacting for more than 2 hours, a sample was taken for infrared analysis, and when the result showed no -NCO group, a polyurethane structure-modified epoxy resin composition was prepared. The type and amount of epoxy resin mixture used, and the amount of diphenylmethane diisocyanate (MDI) are shown in Table 7.

[0078] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com