Preparation method of boron doped graphene

A technology of graphene and boron doping, applied in the direction of graphene, nano-carbon, etc., can solve the problem of low boron content in boron-doped graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

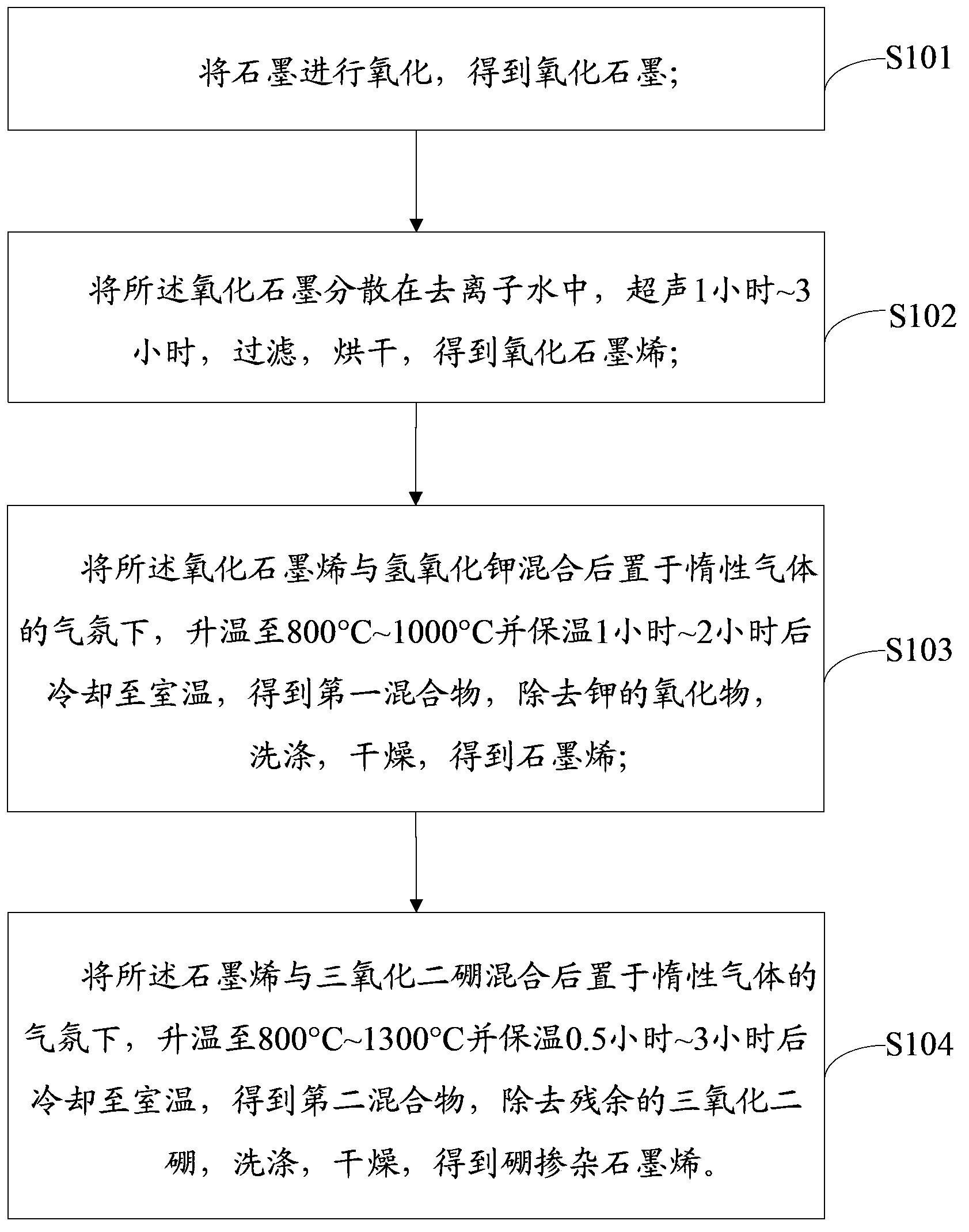

[0028] see figure 1 , the preparation method of the boron-doped graphene of an embodiment comprises the following steps:

[0029] S101, oxidize the graphite to obtain graphite oxide.

[0030] The specific steps are: add graphite to the mixed solution of concentrated sulfuric acid and concentrated nitric acid, stir in an ice-water mixing bath while keeping the temperature at about 0°C; then slowly add potassium permanganate to the mixed solution In the process, because potassium permanganate has strong oxidizing properties under acidic conditions, graphite can be oxidized; then the mixed solution is heated to 85°C for reaction and kept for 30 minutes. During the heat preservation process, graphite can be further oxidized ; Add deionized water, continue to maintain 85 ° C temperature for 30 minutes; then add hydrogen peroxide to the mixed solution, remove excessive potassium permanganate, obtain graphite oxide solution; graphite oxide solution is suction filtered to obtain a so...

Embodiment 1

[0043] (1) Preparation of graphite oxide: Weigh 1 g of graphite with a purity of 99.5%, add 90 mL of concentrated sulfuric acid with a mass fraction of 98% and 25 mL of concentrated nitric acid with a mass fraction of 65%, and place the mixed solution in Stir in an ice-water mixed bath for 20 minutes; then slowly add 6g of potassium permanganate to the mixed solution and stir for 1 hour; then heat the mixed solution to 85°C and keep it for 30 minutes; then add 92mL of deionized water Continue to keep at 85°C for 30 minutes; then add 10mL hydrogen peroxide solution with a mass fraction of 30%, and stir for 10 minutes; filter the mixed solution with suction, and then use 100mL dilute hydrochloric acid and 150mL deionized water to treat the solids successively. Washing, a total of three washings, one of the washing process is to first place the solid in dilute hydrochloric acid, suction filtration, after the filtrate is drained, pour it into deionized water for suction filtration....

Embodiment 2

[0048] (1) Preparation of graphite oxide: Weigh 1 g of graphite with a purity of 99.5%, add 90 mL of concentrated sulfuric acid with a mass fraction of 98% and 25 mL of concentrated nitric acid with a mass fraction of 65%, and place the mixed solution in Stir in an ice-water mixed bath for 20 minutes; then slowly add 6g of potassium permanganate to the mixed solution and stir for 1 hour; then heat the mixed solution to 85°C and keep it for 30 minutes; then add 92mL of deionized water Continue to keep at 85°C for 30 minutes; finally add 10mL hydrogen peroxide solution with a mass fraction of 30%, and stir for 10 minutes; filter the mixed solution with suction, and then use 100mL dilute hydrochloric acid and 150mL deionized water to treat the solids successively. Washing, washing three times in total, finally the solid was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0049] (2) Preparation of graphene oxide: disperse the graphite oxide obtained in (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com