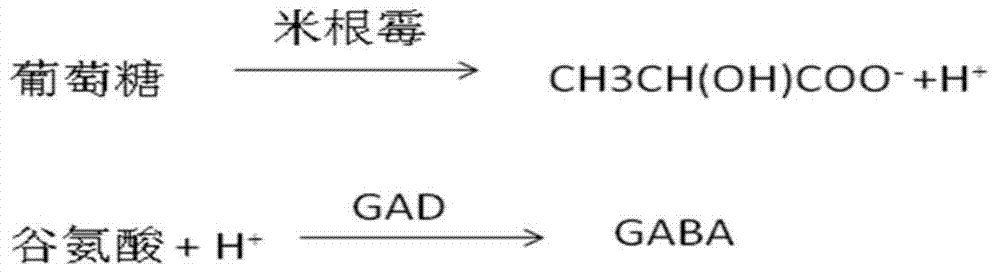

Method for producing lactic acid and simultaneously realizing coupling preparation of GABA (gamma-aminobutyric acid)

A technology of lactic acid and sodium glutamate, applied in the field of biochemical engineering, can solve the problems of solidification, consumption of industrial raw materials, difficult to continue fermentation, etc., and achieve the effects of removing product inhibition, reducing production costs, and overcoming a large amount of calcium sulfate waste residue and waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of immobilized glutamic acid decarboxylase engineering bacteria:

[0037] (1) Pick the engineered bacteria of glutamate decarboxylase (E.coli BL21(DE3) / pET28a-gadB, from the activated LB solid medium, (see "Cloning, sequencing and expression of a glutamate decarboxylase gene from the GABA-producing strain Lactobacillus brevis CGMCC1306[J].ANNALS OF MICROBIOLOGY.2012,62(2):689-698") monoclonal cells were injected with kanamycin (50μg·mL -1 ) in LB liquid medium at 37°C with 200r / min shaking overnight to obtain seed liquid.

[0038] (2) Inoculate the seed liquid with 1% inoculum volume fraction into the -1 ) in LB medium, cultured at 37°C, 200r / min until OD 600 Add IPTG at 0.6 o'clock to make the final concentration of IPTG 0.5 μM, induce culture at 30° C., 150 r / min for 6 h.

[0039] (3) Treat the bacterial cells expressing glutamic acid decarboxylase at 70°C for 30 minutes, then collect the bacterial cells by centrifugation to obtain permeabilized glutami...

Embodiment 2

[0042] (1) Inoculate 2% (v / v) Rhizopus oryzae As3.819 spore suspension (5×10 6 cells / mL) in the seed medium, 30°C, 220r / min shaking on the shaker for 24 hours, to obtain the seed liquid.

[0043] (2) Inoculate the seed liquid into 50mL fermentation medium with 4% inoculation amount, and cultivate it at 32°C and 200r / min. When the pH of the fermentation liquid is lower than 4.8, add immobilized corn to the fermentation liquid. Amino acid decarboxylase engineering bacteria (dry cell weight content of bacteria is 23.2mg, total activity of glutamic acid decarboxylase is 150U), pyridoxal phosphate with a final concentration of 0.1mM, and L-sodium glutamate is continuously added at the same time, so that The pH value of the fermentation broth was maintained between 4.8-5.0 throughout the whole process, and the cultivation was continued for 60 hours. At the same time, the fermentation broth without immobilized glutamic acid decarboxylase was used as blank control.

[0044] The cont...

Embodiment 3

[0046] (1) Inoculate 2% (v / v) Rhizopus oryzae spore suspension (5×10 6 cells / mL) in the seed medium, 30°C, 220r / min shaking on the shaker for 24 hours, to obtain the seed liquid.

[0047] (2) Inoculate the seed liquid into 50mL fermentation medium with 4% inoculation amount, and cultivate it at 32°C and 200r / min. When the pH of the fermentation liquid is lower than 4.8, add immobilized corn to the fermentation liquid. Amino acid decarboxylase thallus (the dry cell weight content of the bacterium is 23.2mg, the total activity of glutamic acid decarboxylase is 150U), the final concentration is 0.1mM pyridoxal phosphate, and L-sodium glutamate is continuously added at the same time, so that The pH value of the fermentation broth was maintained between 5.2-5.6 throughout the whole process, and the cultivation was continued for 60 hours. At the same time, the fermentation broth without immobilized glutamic acid decarboxylase was used as blank control.

[0048] The measured conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com