Preparation method of multi-template molecular imprinting integrated bar

A technology of molecular imprinting and template molecules, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., to achieve the effects of easy regulation, suitable thickness and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the multi-template molecularly imprinted monolith described in this embodiment comprises the following steps:

[0030] (1) Clean the hard glass capillary with an inner diameter of 0.5mm, dry it at 150°C, and sinter one end to serve as a reaction vessel for molecularly imprinted polymer preparation;

[0031] (2) Dissolve 0.33 mmol of sulfamethazine, 0.33 mmol of sulfamethoxazole, and 0.33 mmol of trimethoprim in 10 mL of acetonitrile, add 4 mmol of methacrylic acid, mix well, and place in the dark for 12 h. Obtain the pre-assembly solution;

[0032] (3) Add 18 mmol of trimethylolpropane trimethacrylate and 0.5 mmol of azobisisobutyronitrile to the pre-assembly solution in step (2), mix well, degas by ultrasonic for 5 min, and inject with a syringe with an inner diameter of 0.5 mm rigid capillary, heated in a water bath at 45°C to initiate polymerization;

[0033] (4) After polymerization for 20 h, soak overnight in a 1:6 water-hydrofluoric aci...

Embodiment 2

[0038] The preparation method of the multi-template molecularly imprinted monolith described in this embodiment comprises the following steps:

[0039] (1) Clean the hard glass capillary with an inner diameter of 1.0 mm, dry it at 150°C, and sinter one end to serve as a reaction vessel for molecularly imprinted polymer preparation;

[0040] (2) Dissolve 0.66 mmol of sulfamethazine, 0.66 mmol of sulfamethoxazole, and 0.66 mmol of trimethoprim in 10 mL of acetonitrile, add 8 mmol of methacrylic acid, mix well, and place in the dark for 16 h. Obtain the pre-assembly solution;

[0041] (3) Add 18 mmol of trimethylolpropane trimethacrylate and 1 mmol of azobisisobutyronitrile to the pre-assembly solution in step (2), mix well, ultrasonically degas for 5 minutes, and inject with a syringe with an inner diameter of 1.5 mm The rigid capillary tube is heated in a water bath at 75°C to initiate polymerization;

[0042] (4) After polymerization for 28 hours, soak overnight in a 1:2 wat...

Embodiment 3

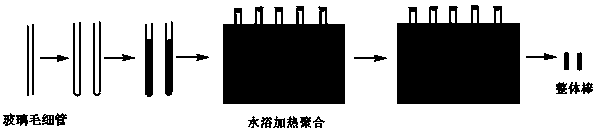

[0047] The preparation method of the multi-template molecularly imprinted monolith described in this embodiment, such as figure 1 shown, including the following steps:

[0048] (1) Wash the hard glass capillary with an inner diameter of 1.5 mm, dry it at 150 °C, and sinter one end to serve as a reaction vessel for molecularly imprinted polymer preparation;

[0049] (2) Dissolve 0.33 mmol of sulfamethazine, 0.33 mmol of sulfamethoxazole and 0.50 mmol of trimethoprim in 10 mL of acetonitrile as template molecules, add 4 mmol of methacrylic acid, mix well, and place in the dark for 14 h to obtain pre-assembly solution;

[0050] (3) Add 18mmol trimethylolpropane trimethacrylate and 0.75mmol azobisisobutyronitrile to the pre-assembly solution in step (2), mix well, ultrasonically degas for 5 min, and inject with a syringe with an inner diameter of 1.0 mm hard capillary, heated in a water bath at 60°C to initiate polymerization;

[0051] (4) After 24 hours of polymerization, soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com