Method for improving broaching precision of mortises in excircle of wheel disc part

A technology for parts and roulettes, which is applied in the field of improving the broaching accuracy of the external circular tongue and groove of roulette parts, can solve the problems of difficulty in guaranteeing the accuracy of the tongue and groove of the deformed parts, and achieve the effects of reducing the deformation amount, simplifying the operation and improving the dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific drawings and embodiments, which are explanations rather than limitations of the present invention.

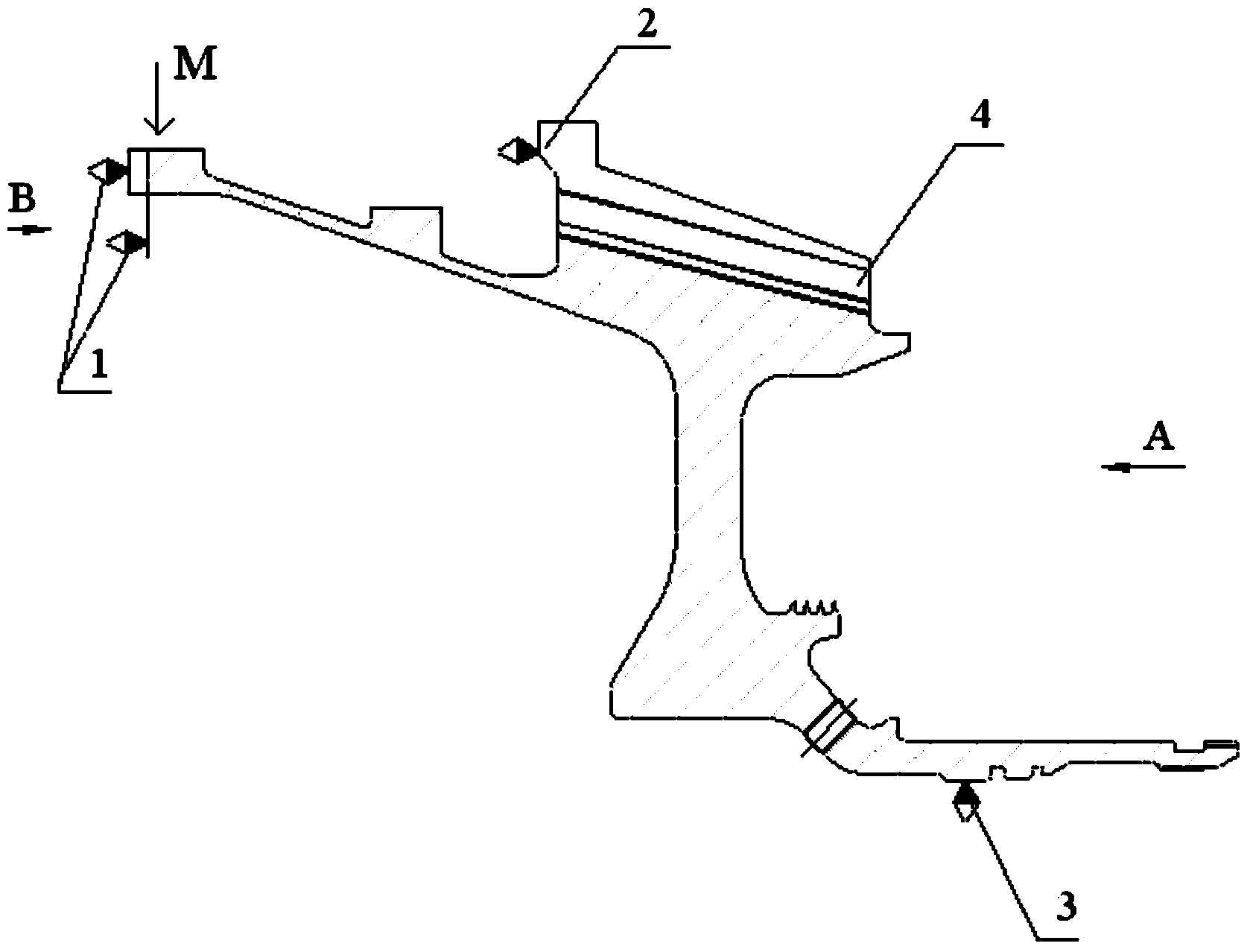

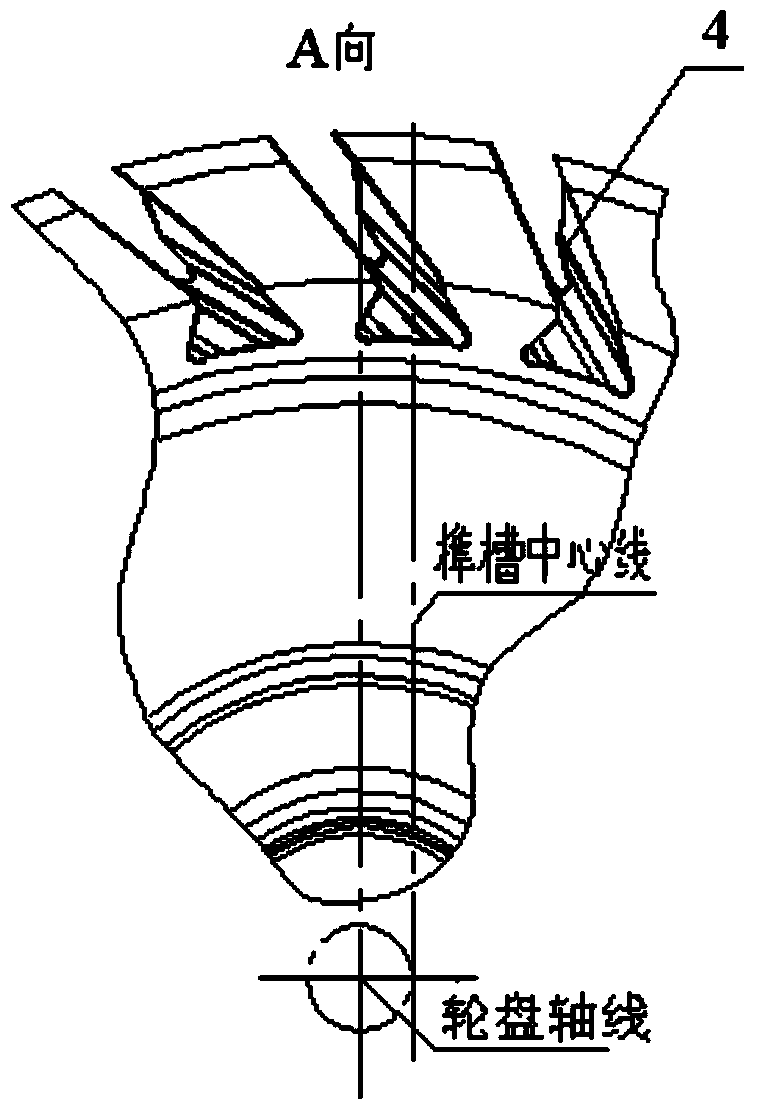

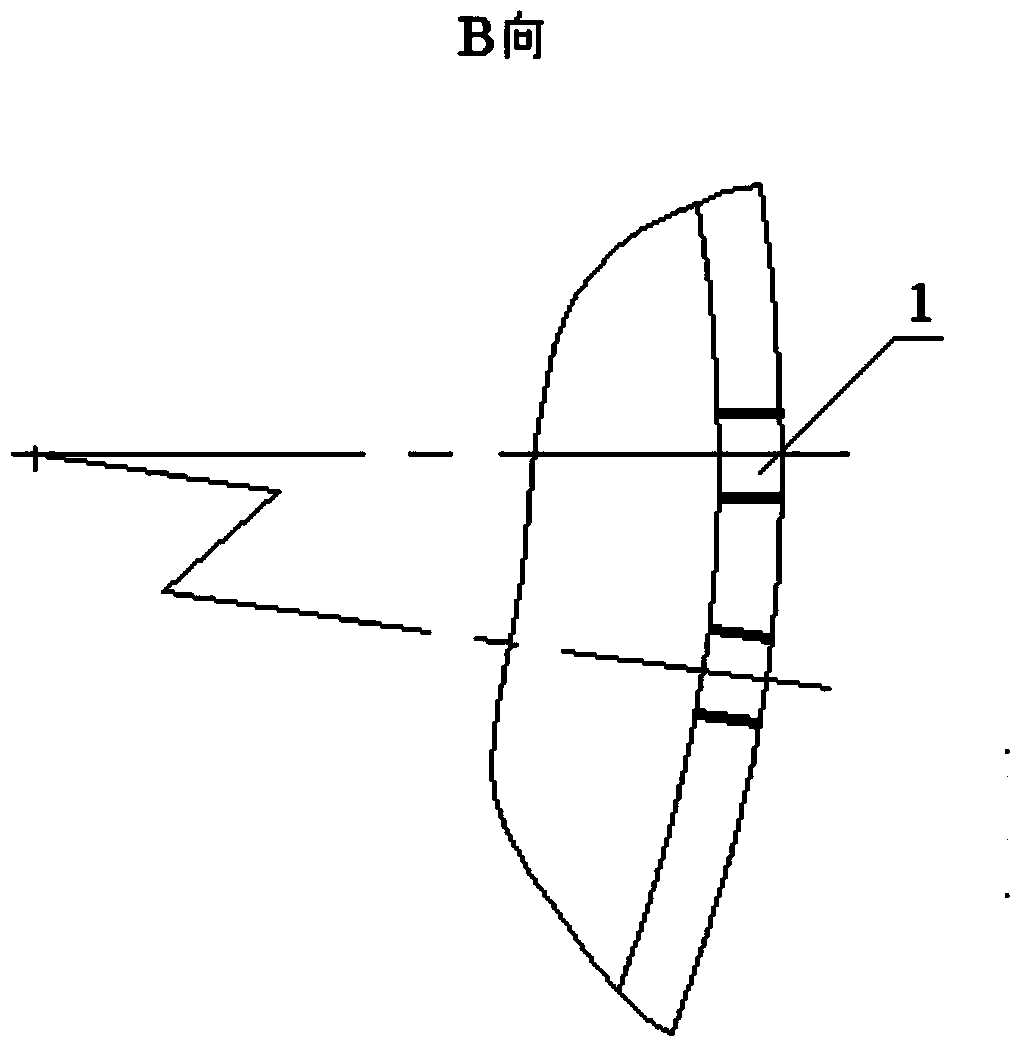

[0020] A method of improving the broaching accuracy of the outer circle tenon and groove of the wheel disc parts of the present invention adopts the design of the outer circle process table, which can increase the radial thickness of the fixture and enhance the rigidity. Two (or three) angular positioning grooves are used to pass Clamping and broaching twice (or three times), increase the circumferential positioning length of the fixture, further enhance the rigidity of the fixture, and divide the tenon and groove into two batches (or three batches) to complete broaching:

[0021] If the number of tenons and grooves on the outer circle of the wheel to be processed is even, the first angular positioning groove can be used for positioning, and the odd-numbered tenons and grooves sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com