Cabazitaxel liposome injection and preparation method thereof

A cabazitaxel and injection technology, which is applied in the field of liposome compositions and their preparation, can solve the problems of leakage of encapsulated substances, liposome fusion, complicated steps, etc., and achieves reduced toxicity, improved bioavailability, and prolonged circulation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 40mg of cabazitaxel, 500mg of egg yolk lecithin, 200mg of hydrogenated soybean lecithin, 100mg of mPEG2000 modified bis-stearylphosphatidylethanolamine (DSPE-mPEG2000), 10mg of cholesterol in a 500ml round-bottomed flask, dissolve in 200ml of absolute ethanol, Rotary evaporator on a constant temperature water bath at 55-60°C evaporates ethanol at 100rpm and reduced pressure, so that phospholipids and drugs form a uniform lipid film at the bottom of the flask, and add 8ml of 5% mannitol aqueous solution to the above-mentioned round bottom flask Wash the membrane with a rotary evaporator at 50°C until the lipid film is hydrated and turns into a white liposome suspension, and extrude the whole particle through 0.4, 0.2, and 0.1 μm in sequence (3 times each) to obtain the product. Dissolve 8000 mg of sucrose in liposomes, after sterile filtration (membrane filter pore size 0.2 μm), the final dispersion is divided into vials, and then freeze-dried.

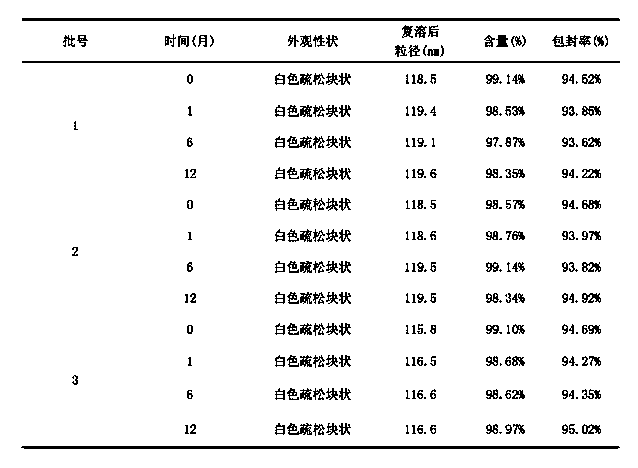

[0021] After the fre...

Embodiment 2

[0023] Weigh 10mg of cabazitaxel, 335mg of soybean lecithin, 5mg of cholesterol and 15mg of mPEG2000 modified distearoylphosphatidylethanolamine (DSPE-mPEG2000) into a 100ml round-bottomed flask and dissolve in 50ml of chloroform / methanol (1:1) mixed solvent , on a constant temperature water bath at 55-60°C with a rotary evaporator at 100rpm and under reduced pressure to evaporate the mixed solvent, so that the phospholipids and drugs form a uniform lipid film at the bottom of the flask, and add 3.5ml of 5% glucose aqueous solution to the above In a round-bottomed flask, rotate and wash the film with a rotary evaporator at 50°C until the lipid film is hydrated and becomes a white liposome suspension, and then extrude the whole particle through 0.4, 0.2, and 0.1 μm in sequence (3 times each), that is, have to. Dissolve 700 mg of glucose in liposomes, after sterile filtration (membrane filter pore size 0.2 μm), the final dispersion is divided into vials, and then freeze-dried. ...

Embodiment 3

[0026] Weigh 10mg of cabazitaxel, 400mg of soybean lecithin, 50mg of double myristyl phosphatidylglycerol (DMPG) and 7.5mg of cholesterol into a 100ml round bottom flask, dissolve in 50ml of chloroform / methanol (1:1) mixed solvent, and place at 55~ Rotary evaporator on a constant temperature water bath at 60°C evaporates the mixed solvent under the condition of 100rpm and reduced pressure, so that phospholipids and drugs form a uniform lipid film at the bottom of the flask, and add 3.5ml 5% glucose aqueous solution to the above round bottom flask , rotate and wash the membrane with a rotary evaporator at 50°C until the lipid film is hydrated and becomes a white liposome suspension, and then extrude the whole pellet through 0.4, 0.2, and 0.1 μm in turn (3 times each), that is, 450mg Mannitol was dissolved in liposomes, and after sterile filtration (membrane filter pore size 0.2 μm), the final dispersion was dispensed into vials and freeze-dried.

[0027] After the freeze-dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com