Anti-acarid polyester fiber and preparation method thereof

A polyester fiber and anti-mite technology, which is applied in the field of anti-mite polyester fiber and its preparation, can solve the problems of easy decomposition, easy volatilization, and few types of anti-mite agents, and achieve good processing performance, good anti-mite effect, and improved resistance. The effect of washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] (1), add 81 grams of N'N-dimethylformamide in the there-necked flask, then add 1 gram of phenbutyltin and 19 grams of polyaspartic acid, and then add acetic acid, so that the initial pH of the entire reaction system is 3. Stir and heat to 90°C, react for 3 hours, and after the reaction, distill the reaction solution under reduced pressure to obtain 16 grams of anti-mite powder;

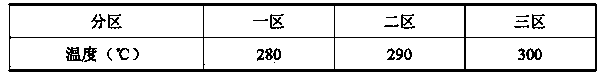

[0020] (2), after stirring and mixing 5 grams of the above-mentioned anti-mite powder and 495 grams of polyester resin slices, a twin-screw extruder is used to carry out blending and granulation to obtain anti-mite polyester slices. The content in the chips is 5% by weight; the feed screw speed is 50r / min, the main screw speed is 120r / min, the twin-screw extruded filaments are cooled in a water bath, and the anti-mite masterbatch is obtained by pelletizing with a pelletizer, and the cutting speed is 400r / min, the temperature of each zone of the twin-screw extruder is shown in Table 1:

[0021]...

example 2

[0027] (1), add 85 grams of N'N-dimethylformamide in the there-necked flask, then add 5 grams of phenbutyltin and 15 grams of polyaspartic acid, then add acetic acid, so that the initial pH of the whole reaction system is 3. Stir and heat to 90°C, react for 3 hours, and after the reaction, distill the reaction solution under reduced pressure to obtain 18 grams of anti-mite powder;

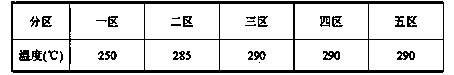

[0028] (2), after stirring and mixing 15 grams of the above-prepared anti-mite powder and 485 grams of polyester resin slices, a twin-screw extruder is used to carry out blending and granulation to obtain anti-mite polyester slices. The content in the chips is 3% by weight; the feeding screw speed is 50r / min, the main screw speed is 120r / min, the twin-screw extruded filaments are cooled in a water bath, and the anti-mite masterbatch is obtained by pelletizing with a pelletizer, and the cutting speed is 400r / min, the temperature of each zone of the twin-screw extruder is as follows in Table 3:

[0...

example 3

[0034] (1), add 90 grams of N'N-dimethylformamide in the there-necked flask, then add 10 grams of phenbutyltin and 10 grams of polyaspartic acid, and then add acetic acid, so that the initial pH of the entire reaction system is 3. Stir and heat to 90°C, react for 3 hours, and after the reaction, distill the reaction solution under reduced pressure to obtain 16 grams of anti-mite powder;

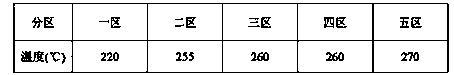

[0035] (2), after stirring and mixing 5 grams of the above-mentioned anti-mite powder and 495 grams of polyester resin slices, a twin-screw extruder is used to carry out blending and granulation to obtain anti-mite polyester slices. The content in the chips is 1% by weight; the feed screw speed is 50r / min, the main screw speed is 120r / min, the twin-screw extruded filaments are cooled in a water bath, and the anti-mite masterbatch is obtained by pelletizing with a pelletizer, and the cutting speed is 400r / min, the temperature of each zone of the twin-screw extruder is shown in Table 5:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com