Soft transparent polyimide film

A transparent polyimide and polyimide resin technology, applied in the field of polymer materials, can solve the problems of insufficient flexibility and low light transmittance, and achieve the effects of improved performance, high transparency and excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

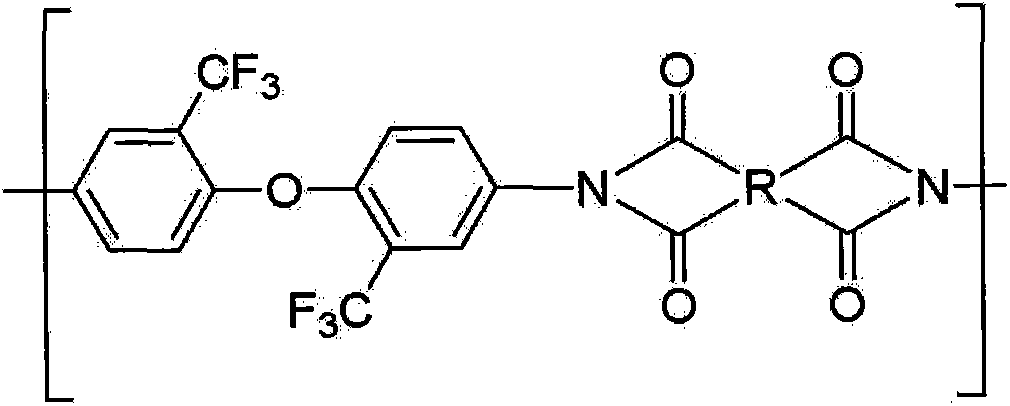

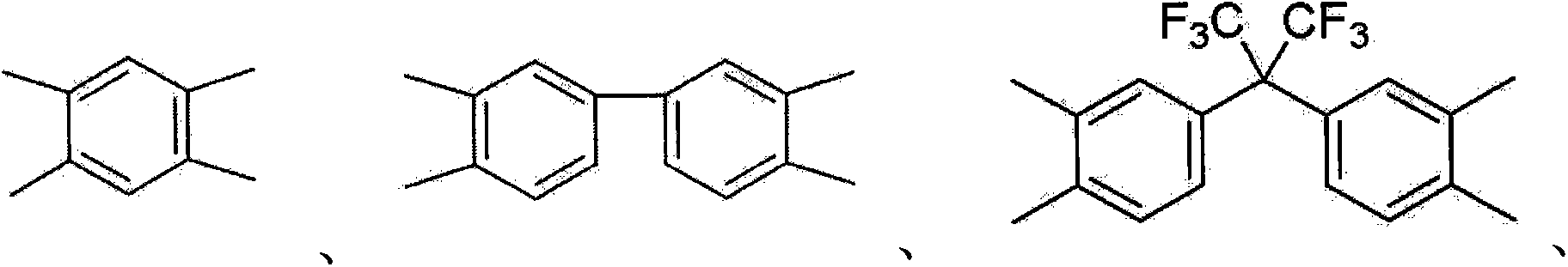

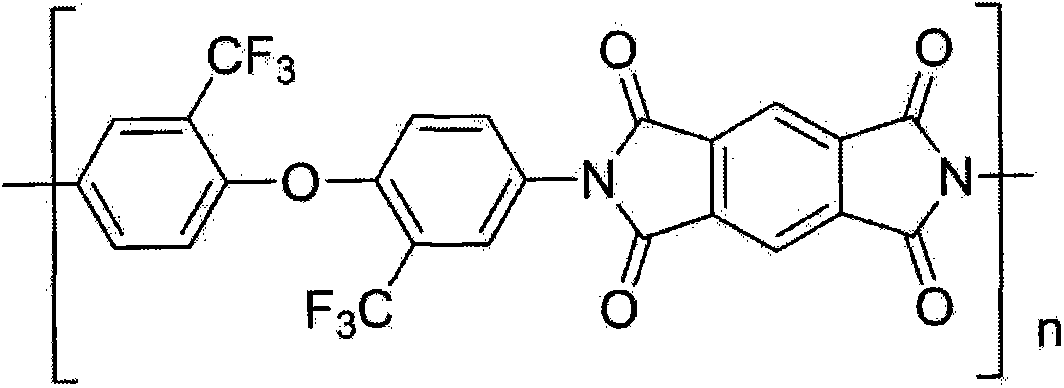

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, 1.3450 grams (0.004 moles) of 2,2'-bistrifluoromethyl-4,4'-diaminodiphenyl ether (TFODA) and 0.8725 grams (0.004 moles) of pyromellitic dianhydride (PMDA ) was dissolved in 8.87 g of N,N-dimethylacetamide, 50 mg of isoquinoline was added, heated (200° C.) under nitrogen protection for reflux reaction for 12-50 hours, cooled and poured into ethanol to precipitate polyimide resin , washing and drying with ethanol to obtain a polyimide resin;

[0030] Dissolve polyimide resin and 0.5g insect wing extract in 10g N,N-dimethylacetamide, coat the film on the substrate, first dry at 80-90°C for 3-5 hours, and then dry at 60°C For one step, the temperature was raised to 200°C, and each step was maintained for 121 minutes, then cooled naturally, and the film was stripped to obtain a flexible and transparent polyimide film.

[0031] The extraction method of the above-mentioned insect wing extract is as follows: grind the insect wing into powder, first soak it...

Embodiment 2

[0036] At room temperature, 1.3450 g (0.004 mol) of 2,2'-bistrifluoromethyl-4,4'-diaminodiphenyl ether (TFODA) and 1.1769 g (0.004 mol) of 3,3',4,4 Dissolve '-biphenyltetracarboxylic dianhydride (BPDA) in 8.87 g of N,N-dimethylacetamide, add 1 g of benzoic acid, and heat (200° C.) under nitrogen protection for reflux reaction for 12-50 hours. After cooling Pour into ethanol to precipitate polyimide resin, wash and dry with ethanol to obtain polyimide resin;

[0037] Dissolve polyimide resin and 0.7g insect wing extract in 12g N,N-dimethylacetamide, coat the film on the substrate, first dry at 80-90°C for 3-5 hours, and then dry at 60°C For one step, the temperature was raised to 250° C., and each step was maintained for 128 minutes, and then cooled naturally, and the film was stripped to obtain a flexible transparent polyimide film.

[0038] The extraction method of the above-mentioned insect wing extract is as follows: grind the insect wing into powder, first soak it in dich...

Embodiment 3

[0043] Dissolve 1.3450 g (0.004 mol) of 2,2'-bistrifluoromethyl-4,4'-diaminodiphenyl ether (TFODA) and 1.7770 g (0.004 mol) of hexafluorodianhydride (6FDA) at room temperature Add 50 mg of isoquinoline to 12.29 g of N,N-dimethylacetamide, heat (200°C) under nitrogen protection to reflux for 12-50 hours, pour into ethanol after cooling to precipitate polyimide resin, ethanol Wash and dry to obtain polyimide resin;

[0044] Dissolve polyimide resin and 0.6g insect wing extract in 15g N,N-dimethylacetamide, coat the film on the substrate, first dry at 80-90°C for 3-5 hours, and then dry at 60°C For one step, the temperature was raised to 200°C, and each step was maintained for 121 minutes, then cooled naturally, and the film was stripped to obtain a flexible and transparent polyimide film.

[0045] The extraction method of the above-mentioned insect wing extract is as follows: grind the insect wing into powder, first soak it in dichloromethane for 24-48 hours, then separate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com