Preparation method and application of high-molecular weight polyethylene glycol diacrylate (PEGDA)

A technology of polyethylene glycol diacrylate and polyethylene glycol, which is applied in the field of preparation of high molecular weight polyethylene glycol diacrylate (PEGDA), can solve the problems of increased difficulty in PEGDA synthesis and unsuitable synthesis methods, and achieves Good conversion efficiency and reaction effect, simple preparation steps, and enhanced functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the preparation of PEGDA product

[0064] Add 10g of PEG (molecular weight 3500, sigma, product number P3640) into 150mL of dichloromethane, protect it with argon for 20min, in a water bath at 30°C, add 0.5g of sodium metal, react for 4h to complete the PEG reaction, add 3mL of 25% acrylamide, After 12 hours of reaction, 0.1 g of β-phenylnaphthylamine was added, and vacuum-dried for 24 hours to obtain 11.7 g of PEGDA product.

Embodiment 2

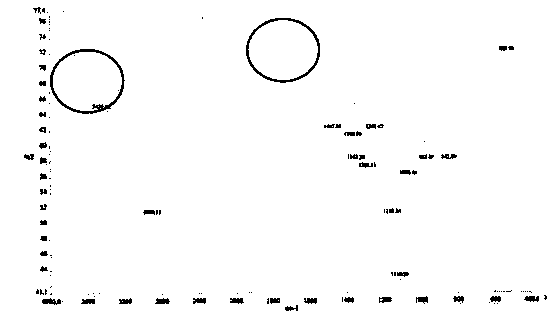

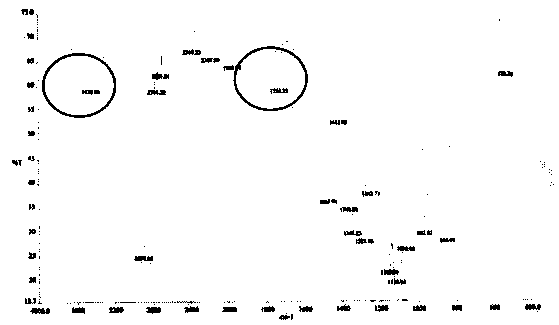

[0065] Embodiment 2: Infrared spectrogram and proton nuclear magnetic resonance spectrum method detect the process of PEGDA product

[0066] Take 1-2 mg of the sample and grind it into a fine powder in an agate mortar, mix it evenly with dry analytically pure potassium bromide powder (about 100 mg, particle size 200 mesh), put it into a mold, and press it into a tablet on a tablet machine. The leaf infrared spectrometer Spectrum65 carried out the spectral measurement of the samples.

[0067] 1H and 13C NMR experimental operation steps, take a small amount of sample into the tube, add 0.5mL deuterated solvent, shake to dissolve the sample, then put the sample into the magnet, open the shimming interface, put the rotor with the sample tube in the Insert above the probe, make the NMR tube enter the probe smoothly, select 1H for test sampling, and select 13C for test sampling in the same operation as above, and obtain 1H and 13C spectra respectively.

[0068] From attached Figu...

Embodiment 3

[0069] Embodiment 3: Gel Permeation Chromatography Determination of PEGDA Molecular Weight

[0070]Select (gel permeation chromatography-multi-angle laser scattering test system (Wyatt Technology, Santa Bar-bara, CA), take a certain amount of 50mg PEGDA and dissolve it in 10mL tetrahydrofuran to prepare a 5mg / mL solution. After overnight, the sample solution passes through the aperture After filtering through a 0.2 μm semi-permeable membrane, inject into the system for measurement. Detection conditions: the mobile phase is chromatographic grade tetrahydrofuran, the flow rate is 0.5mL / min, the temperature is 25°C, and the detector is a multi-angle laser scattering instrument (690nm, DAWN EOS) in conjunction Differential refractometer (690nm Optilab rEX, Wyatt Technology, Santa Barbara, CA), according to the technical report of sigma, the weight-average molecular weight of PEG raw material is 3350, and from the gel permeation chromatography measurement result of PEGDA, the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com