A kind of preparation method of hydrophobic ceramic surface

A ceramic surface and ceramic technology, which is applied in the field of preparation of hydrophobic ceramic surfaces, can solve the problems of difficulty in achieving uniformity and integrity of hydrophobic properties, complicated process, and high cost, and achieve good stability of hydrophobic properties, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Wash the crucible cover with water, dry it in a drying oven and cool it to room temperature for later use.

[0021] The pH value of the 40ml toluene solution was adjusted to 9.0 with an appropriate amount of triethylamine. Next, 50 μL of octadecyltrichlorosilane was added dropwise to the above solution, dispersed by ultrasonic (frequency 25 kHz), and the crucible lid was immersed in the above solution for 5 minutes under the condition of ultrasonic oscillation. Two drops of distilled water were added dropwise to 2 mL of acetone solution to form a mixed solution, and the mixed solution was added dropwise to the above solution, and 0.05 g of zinc powder was added, and ultrasonic oscillation was continued for 5 minutes. From the above solution, take out the crucible lid and wash it with ethanol, acetone, distilled water to prepare a crucible lid with a hydrophobic surface.

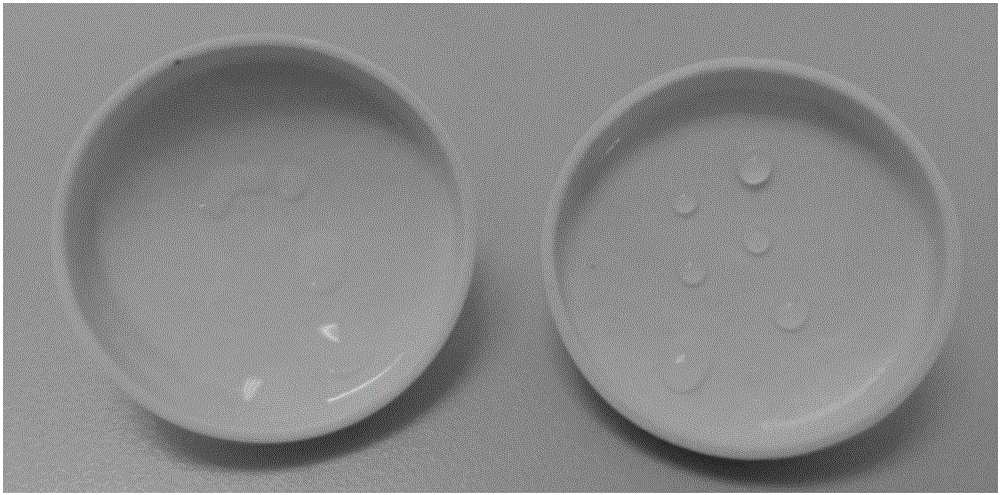

[0022] After the crucible cover is processed by the present invention, the droplet effect formed b...

Embodiment 2

[0024] Wash the crucible cover with water, dry it in a drying oven and cool it to room temperature for later use.

[0025] The pH value of the 40ml ethanol solution was adjusted to 10.0 with an appropriate amount of triethylamine. Next, 40 μL of octadecyltrichlorosilane was added dropwise to the above solution, dispersed by ultrasonic (frequency 25 kHz), and the crucible lid was immersed in the above solution for 3 minutes under the condition of ultrasonic oscillation. Two drops of distilled water were added dropwise to 2 mL of acetone solution to form a mixed solution, and the mixed solution was added dropwise to the above solution, and 0.05 g of aluminum powder was added, and ultrasonic oscillation was continued for 5 minutes.

[0026] From the above solution, take out the crucible lid and wash it with ethanol, acetone, distilled water to prepare a crucible lid with a hydrophobic surface.

[0027] After being treated by the method of the invention, the hydrophobic property ...

Embodiment 3

[0029] Wash the crucible cover with water, dry it in a drying oven and cool it to room temperature for later use.

[0030] Use an appropriate amount of triethylamine to adjust the pH value of 40ml of the mixed solution of toluene and ethanol (volume ratio 1:1) to 9.0. Next, 40 μL of octadecyltrichlorosilane was added dropwise to the above solution, dispersed by ultrasonic (frequency 25 kHz), and the crucible lid was immersed in the above solution for 5 minutes under the condition of ultrasonic oscillation. Two drops of distilled water were added dropwise to 2 mL of acetone solution to form a mixed solution, and the mixed solution was added dropwise to the above solution, and 0.05 g of zinc powder was added, and ultrasonic oscillation was continued for 5 minutes. From the above solution, take out the crucible lid and wash it with ethanol, acetone, distilled water to prepare a crucible lid with a hydrophobic surface.

[0031] After being treated by the method of the invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com