A kind of high-performance colored permeable asphalt concrete and its preparation method

A permeable asphalt, high-performance technology, applied in the field of colored permeable asphalt concrete and its preparation, can solve the problems of destroying the ecological balance of the urban surface, not being able to replenish the urban groundwater, affecting the growth of the urban surface plants, etc., to achieve good visual enjoyment and improvement. City image, the effect of good mood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of high-performance colored permeable asphalt concrete: the raw material formula is: according to the mass ratio, 25 parts of heavy oil, 2 parts of SBS, 3 parts of SBR, 20 parts of C5 petroleum resin, 1.0 part of silane coupling agent, 20 parts of pigment (iron oxide), 1000 parts of medium-sized ore type I graded ore.

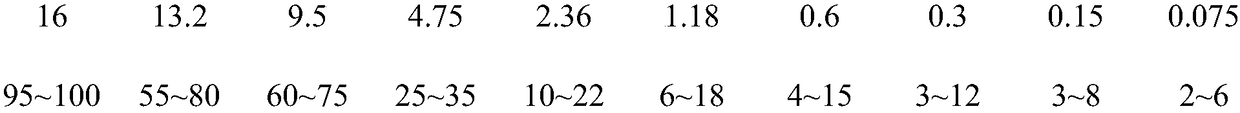

[0052] The medium-sized ore I meets the following requirements:

[0053] The mass percentage of the ore passing through the square hole sieve with the following sieve holes (mm)

[0054]

[0055] (1) Add 25 parts of heavy oil and 20 parts of C5 petroleum resin according to the above mass ratio, heat to 170°C, fully swell, then add 2 parts of SBS and 3 parts of SBR, and completely After dissolving to form a uniform mixture and stirring and mixing evenly, the colorless binder for high-performance colored asphalt can be prepared (see Table 2 for performance);

[0056] (2) Mix 20 parts of the colorless binder for high-performance co...

Embodiment 2

[0058] A preparation method of high-performance colored permeable asphalt concrete: the raw material formula is: according to the mass ratio, 25 parts of heavy oil minus tetrahydrogenation and rewetting, 5 parts of TPS, 2 parts of SBR, 22 parts of C5 petroleum resin, and 1.0 parts of silane coupling agent Parts, 18 parts of pigment (iron oxide), 1000 parts of medium-sized mineral material II type graded mineral material.

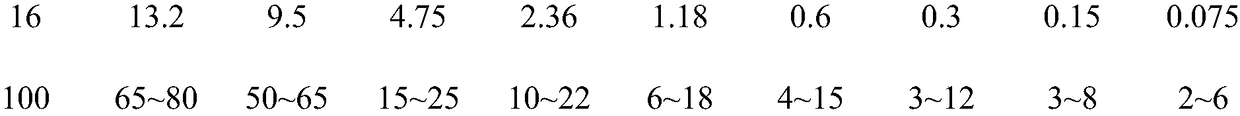

[0059] Medium-sized ore II meets the following requirements:

[0060] The mass percentage of the ore passing through the square hole sieve with the following mm sieve holes

[0061]

[0062] (1) According to the above mass ratio, add 25 parts of heavy oil minus tetrahydrogenated remoisturization and 22 parts of C5 petroleum resin, heat to 175°C, fully swell, then add 5 parts of TPS and 2 parts of SBR, and undergo high-speed shearing After completely dissolving to form a uniform mixture and stirring and mixing evenly, the colorless binder for high-perform...

Embodiment 3

[0065] A preparation method of high-performance colored permeable asphalt concrete: the raw material formula is: according to the mass ratio, 20 parts of KP6040, 10 parts of heavy oil, 3 parts of SBS, 3 parts of SBR, 3 parts of EVA, 21 parts of C9 petroleum resin, silane 1.0 parts of coupling agent, 20 parts of pigment (iron oxide), 1000 parts of fine-grained mineral material Type I graded mineral material.

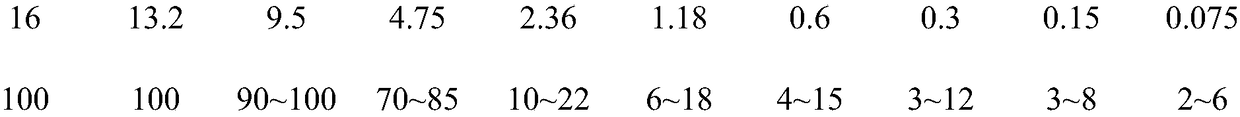

[0066] Fine-grained mineral material I meets the following requirements:

[0067] The mass percentage of the ore passing through the square hole sieve with the following mm sieve holes

[0068]

[0069] (1) According to the above mass ratio, add 20 parts of KP6040, 10 parts of heavy oil and 21 parts of C9 petroleum resin, under the condition of heating to 170 ℃, fully swell, then add 3 parts of SBS, 3 parts of SBR, 3 parts of 1 part of EVA, after being completely dissolved by high-speed shearing to form a uniform mixture and stirred evenly, the colorless binder for hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com