Energy recycling system and method for liquid hydrogen fuel cell car

A fuel cell and energy recovery technology, applied in electric vehicles, electric braking systems, vehicle energy storage, etc., can solve the problems of inability to achieve high-efficiency energy recovery, low operating efficiency, and low operating efficiency of DC choppers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

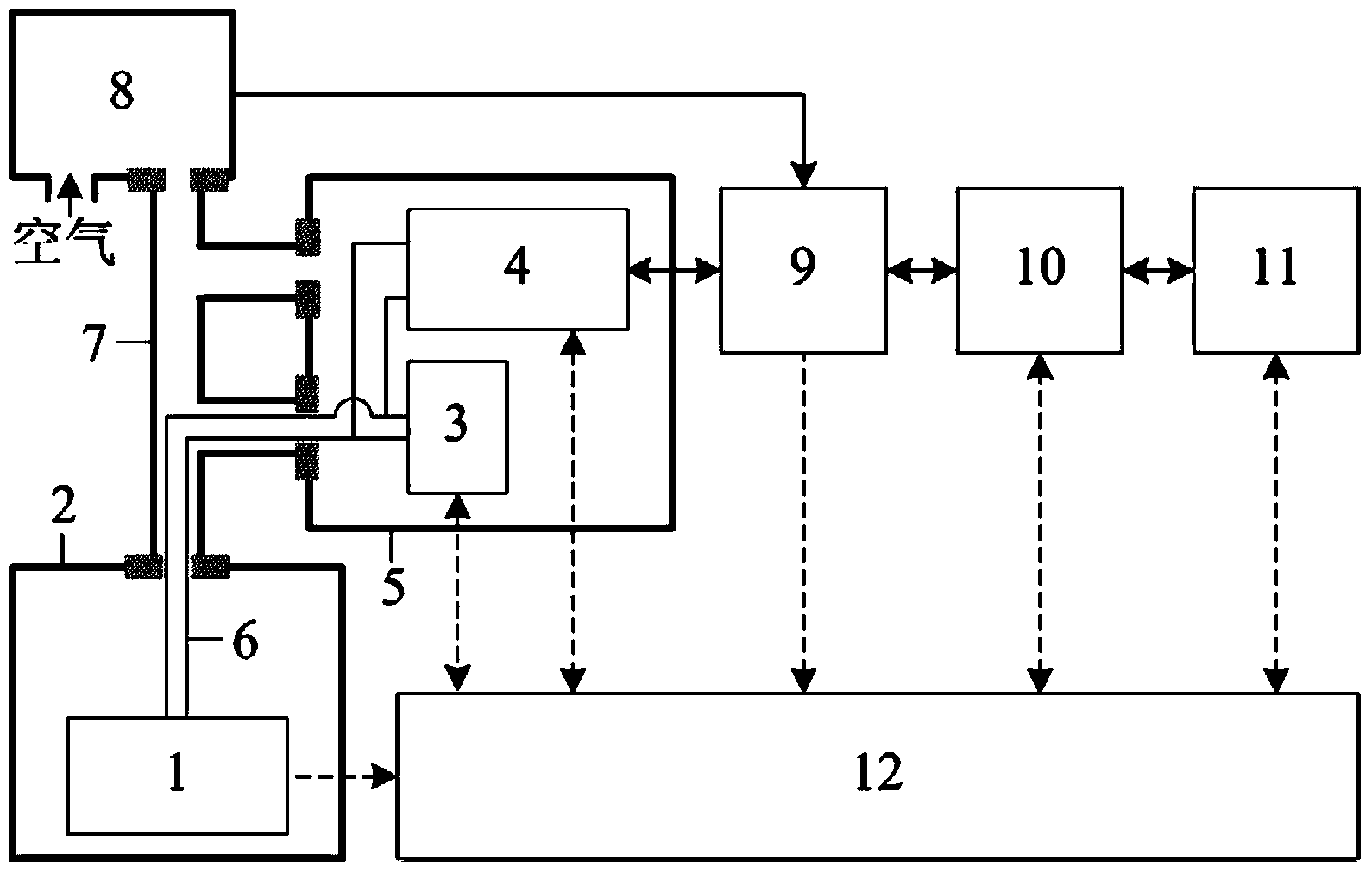

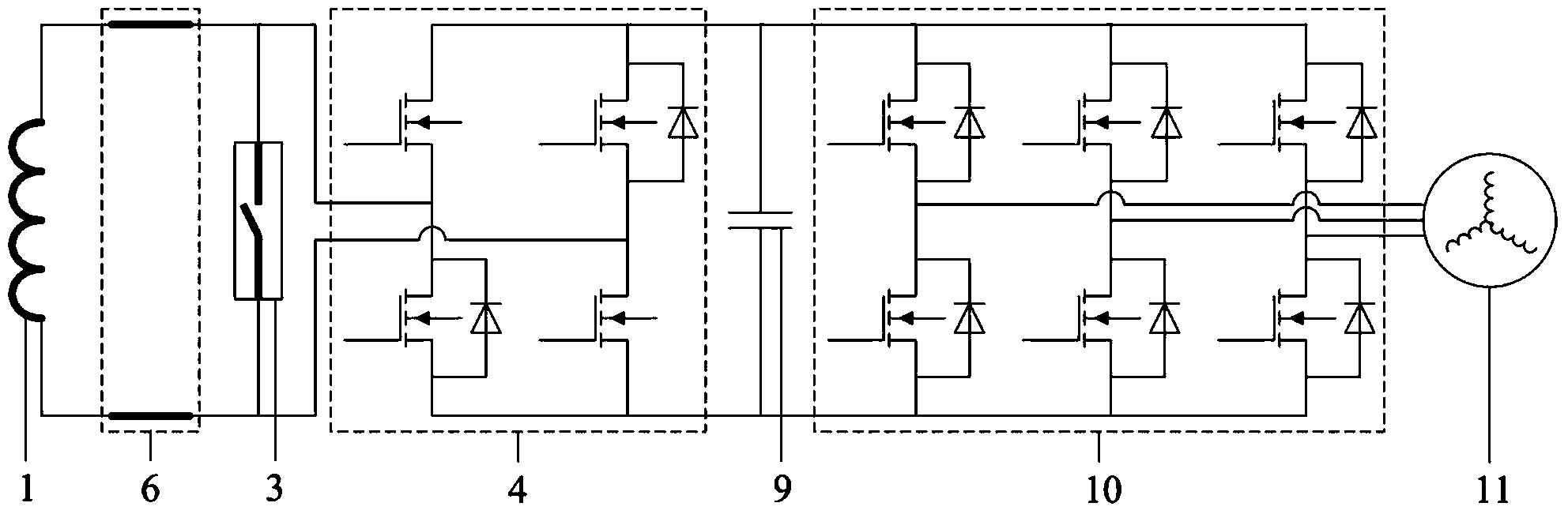

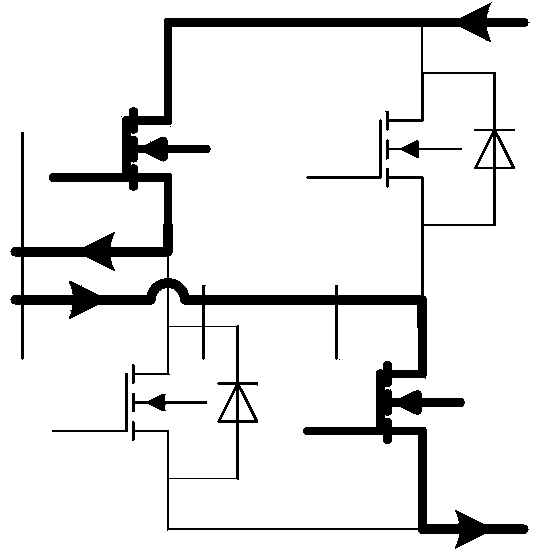

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 shown. Aiming at an existing liquid hydrogen fuel cell vehicle, the system of the present invention is used to perform energy recovery and utilization operation. The system is connected to a vehicle-mounted liquid hydrogen fuel cell 8, and includes a superconducting coil 1 immersed in a liquid hydrogen container 2, a superconducting switch 3 installed in a low-temperature Dewar 5, a full-bridge DC chopper 4, and a low-temperature hydrogen Pipeline 7 , superconducting current leads 6 arranged in cryogenic hydrogen pipeline 7 , DC link capacitor 9 , DC-AC bidirectional converter 10 , on-board motor 11 and measurement and control system 12 .

[0049]Among them, the superconducting current lead 6 is used to connect the superconducting coil 1, the superconducting switch 3 and the full-bridge DC chopper 4; the superconducting coil 1 is made of BSCCO wire, and its inducta...

Embodiment 2

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the same place as in Embodiment 1 will not be repeated, the difference is that: the superconducting coil 1 is made of YBCO wire; the superconducting current lead 6 is a YBCO wire; the low-temperature hydrogen pipeline 7 is a thermally insulated low-temperature hard tube ; The low-temperature Dewar 5 is an adiabatic low-temperature glass fiber reinforced plastic container; the superconducting switch 3 is a magneto-controlled superconducting switch.

Embodiment 3

[0064] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the same place as in Embodiment 1 will not be repeated, the difference is that the superconducting coil 1 is made of MgB 2 The wire is wound; the superconducting current lead 6 is MgB 2 wire; the superconducting switch 3 is a heat-controlled superconducting switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com