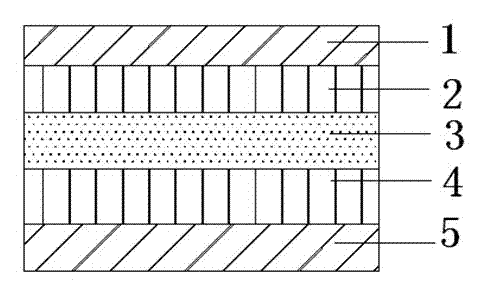

Five-layer co-extrusion packaging material having high moisture barrier and barrier properties and preparation method thereof

A packaging material and high-barrier technology, applied in packaging, wrapping paper, lamination devices, etc., can solve the problems of decreased barrier properties, poor chemical and physical modification effects, etc., achieve excellent moisture barrier properties, and easy to solve barrier properties. The effect of falling and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add LLDPE resin, PA6 resin, pre-mixed 30% calcium oxide / LLDPE composite material, EVOH resin, and HDPE resin to the five extruder hoppers of the five-layer co-extruder in sequence, and set the volume of each material. Process temperature and screw speed, co-extrusion molding, obtain the LLDPE / PA6 / 30%CaO+LLDPE / EVOH / HDPE five-layer co-extrusion composite packaging material that comprises successive contact; The five-layer composite co-extrusion packaging material, After cooling and shaping, corona treatment was carried out on the outer surface to obtain a five-layer co-extrusion packaging material with high moisture resistance and high barrier. Its barrier and moisture resistance properties are shown in Table 1.

Embodiment 2

[0023] Add HDPE resin, EVOH resin, pre-mixed 50% calcium oxide / LLDPE composite material, EVOH resin, and LDPE resin to the five extruder hoppers of the five-layer co-extrusion machine in sequence, and set the volume of each material. Process temperature and screw speed, co-extrusion molding, obtain the HDPE / EVOH / 50%CaO+LLDPE / EVOH / LDPE five-layer co-extruded composite packaging material that comprises successive contact; The five-layer composite co-extruded packaging material, After cooling and shaping, corona treatment was carried out on the outer surface to obtain a five-layer co-extrusion packaging material with high moisture resistance and high barrier. Its barrier and moisture resistance properties are shown in Table 1.

Embodiment 3

[0025] Add LLDPE resin, EVOH resin, pre-mixed 70% calcium oxide / LLDPE composite material, EVOH resin, and PP resin to the five extruder hoppers of the five-layer co-extrusion machine in sequence, and set the volume of each material. Process temperature and screw speed, co-extrusion molding, obtain the LLDPE / EVOH / 70%CaO+LLDPE / EVOH / PP five-layer co-extruded composite packaging material that comprises sequential contact; The five-layer composite co-extruded packaging material, After cooling and shaping, corona treatment was carried out on the outer surface to obtain a five-layer co-extrusion packaging material with high moisture resistance and high barrier. Its barrier and moisture resistance properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com