A preparation method of titanium-nickel alloy anti-counterfeiting mark with hidden information

An anti-counterfeiting mark, titanium-nickel technology, applied in the field of anti-counterfeiting marks, can solve problems such as limited application, and achieve the effects of convenient detection, improved imitation difficulty, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

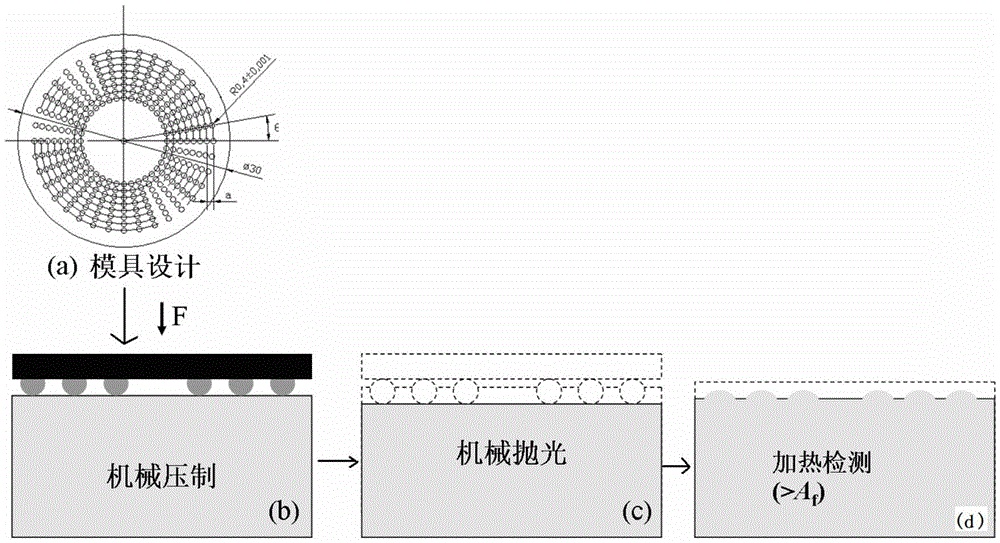

[0019] A method for preparing anti-counterfeiting marks of titanium-nickel alloys with hidden information. The anti-counterfeiting marks of titanium-nickel shape memory alloy materials are prepared by using titanium-nickel shape memory alloy rods containing Ti with an atomic ratio of 50.9%. The initial phase of the material is Mixed phase of martensite and austenite; cf. figure 1 , the specific process includes the following steps:

[0020] Step 1, the preparation of male die,

[0021] Before using the mechanical pressing method to press the pit pattern on the surface of the titanium-nickel material with shape memory effect, it is necessary to prepare a positive mold. The preparation process of the positive mold is as follows: first process the basic mold with the anti-counterfeiting pattern, and then blow dry after ultrasonic cleaning to remove surface oil and other attachments; evenly coat a layer of adhesive on the end face of the basic mold, Stick the steel ball d to the...

Embodiment 1

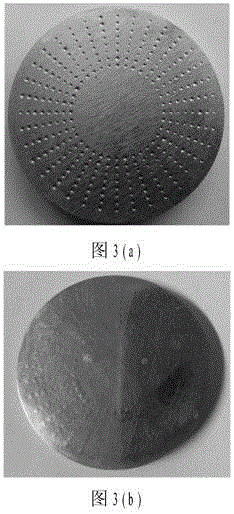

[0028] image 3 It is the physical picture of the pit pattern and the raised pattern of the anti-counterfeiting component in the first embodiment of the present invention, and Fig. 4 is the 3D view of the pressed pit and the raised bump after mechanical polishing and heating in the first embodiment of the present invention.

[0029] Step 1. Preparation of positive mold

[0030] The production process of the male mold used in the test is as follows: put the circular steel base mold with a diameter of 10-30mm and a thickness of 5mm with anti-counterfeiting patterns into alcohol and acetone in sequence, and ultrasonic cleaning for 10 minutes each to remove surface oil and dirt. After other attachments, dry them; apply a layer of adhesive evenly on the end face of the steel sheet, and quickly stick a GCr15 steel ball with an appropriate diameter to the corresponding end face; press a 10-100kg steel plate on the steel ball On the plane, until the steel ball is firmly bonded to the...

Embodiment 2

[0036] Step 1. Preparation of positive mold

[0037] The male mold used in the test is selected from the existing commercialized molds, and its surface features are raised numbers 1-9, refer to Figure 2(b).

[0038] Step 2. Preparation of anti-counterfeiting labels

[0039] Using the above-mentioned commercialized male die, the surface of the TiNi alloy cylinder with a diameter of 6 mm is mechanically pressed to form a pit surface, and the surface of the TiNi alloy is pressed with a digital pattern of pits. Sandpaper and canvas were used to mechanically polish the surface of the titanium-nickel alloy sample after pressing micropores. The polishing depth is until the pit pattern on the surface of the titanium-nickel alloy disappears, and the surface roughness is about 0.12 μm. According to the degree of pattern suppression, the mechanically polished titanium-nickel shape memory alloy can be cut into several slices implying a pattern or a group of characters by wire cutting me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com