Targeting and slow-release antineoplastic medicine nanoparticle with amphiphilic polyurethane as carrier and preparation method thereof

A technology of anti-tumor drugs and nano-microspheres, which is applied in the field of anti-tumor drug nano-microspheres and its preparation, which can solve the problems that the slow-release dosage forms have not been paid attention to, and achieve the effects of uniform size, smooth shape, and prolonged release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] An anti-tumor drug nanosphere with targeting and sustained release effect using amphiphilic polyurethane as a carrier, characterized in that the specific scheme is as follows:

[0049] Microemulsion technology is emulsified solvent evaporation method.

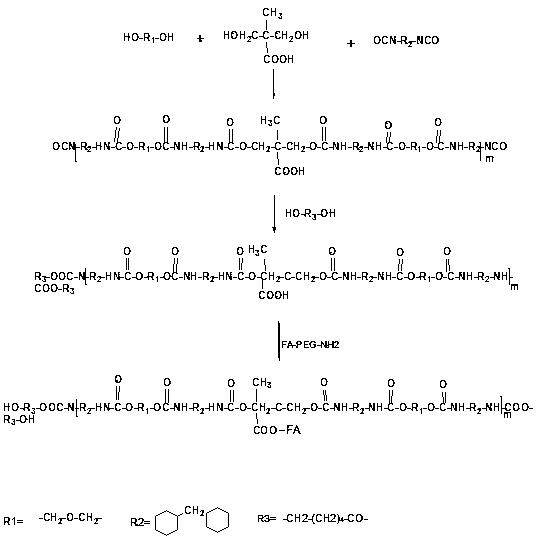

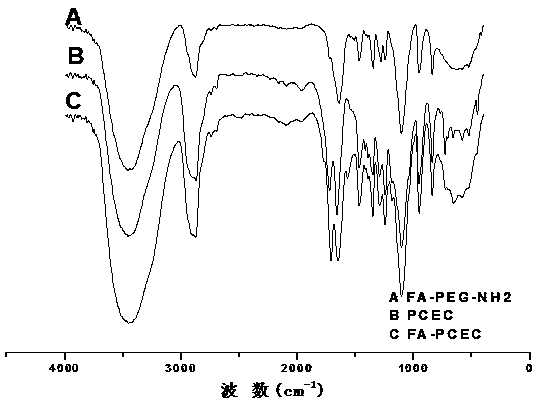

[0050] Step 1: preparing amphiphilic polyurethane, comprising the following steps:

[0051] (1) Add 5g PEG and 20mL acetone to a three-necked flask equipped with a stirrer, reflux condenser and thermometer, stir evenly, add 0.36g HMDI to it, slowly raise the temperature to 80°C under the condition of mechanical stirring, stir for 1h, and make it mix Uniform;

[0052] (2) The temperature of the reaction system was raised to 75° C. while stirring, and the temperature was lowered to 30° C. after 1.5 hours of reaction, and 0.20 g of DMPA was added thereto. Raise the temperature to 70°C with mechanical stirring, stir for 1 hour to make it evenly mixed, and then lower the temperature to 30°C.

[0053] (3) Raise the temperat...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

[0066] Step 3 prepares nano-microspheres The method for preparing nano-microspheres by nano-precipitation-dialysis method includes the following steps:

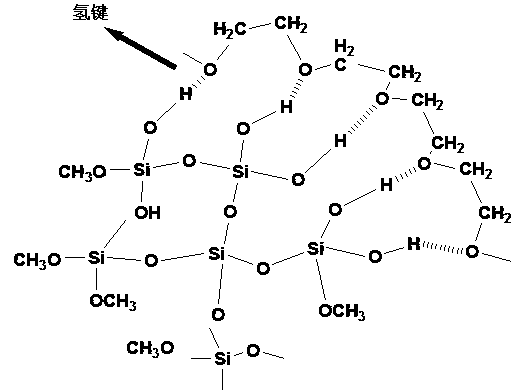

[0067] (1) Take 2 g of FA-PCEC as a solute, dissolve it in 20 mL of dichloromethane, and prepare an oil phase matrix solution with a concentration of 100 mg / mL, and disperse 0.2 g of antineoplastic drug CAP in the above matrix solution to form an oil phase; and Add 0.019g of tetramethoxysilane (TMOS) dropwise to the oil phase, and stir evenly;

[0068] (2) Use polyvinyl alcohol as the solute and water as the solvent to prepare 100 mL of an aqueous solution with a mass fraction of 1.0% polyvinyl alcohol;

[0069] (3) Slowly add the water phase described in step (2) to the oil phase solution described in step (1) drop by drop, and continue to stir at 600rpm for 2 hours; then perform dialysis in distilled water medium, changing every 2 hours Water once, dialy...

Embodiment 3

[0076] The difference between this embodiment and embodiment 1 is:

[0077] Adjust the volume of the PVA aqueous solution in Step (2) of Step 3 in Example 1 to 400 mL, that is, the volume of the second emulsified surfactant solution is 20 times the volume of the organic solvent. The obtained nano-microspheres were tested and characterized with a laser particle size analyzer and a scanning electron microscope, and it was found that the particle size of the nano-microspheres in this example was smaller than that in Example 1, because the increase in the volume of the water phase reduced the viscosity of the oil phase , which is conducive to the dispersion of the oil phase in the water phase to form emulsion droplets, which reduces the particle size of the final microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com