Erasing rubber trade mark paper bundle pasting machine

A technology of erasers and trademarks, applied in labeling machines, labels, packaging, etc., can solve the problems of crowded workshops, low labor efficiency, and no discovery, etc., and achieve the effect of beautiful appearance, improved labor efficiency, and flat shape of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

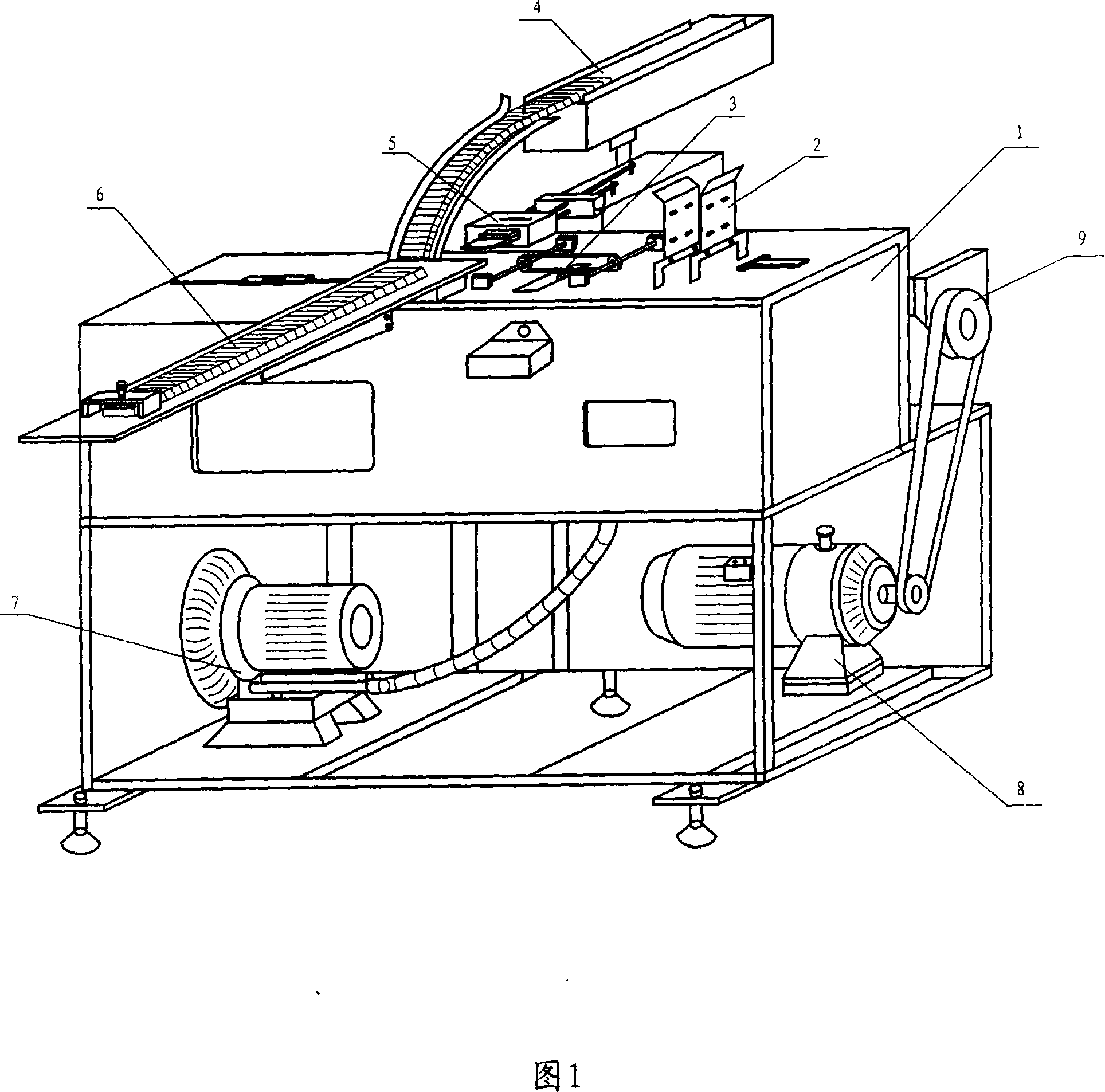

[0020] As shown in Fig. 1, a kind of eraser trademark paper wrapping machine of the present invention, comprises body 1, the paper feeding mechanism 2 that is respectively arranged on the body, gluing mechanism 3, rubber sending mechanism 4, paper folding mechanism 5 and finished product output Mechanism 6, fan 7, motor 8 and transmission device 9; wherein the air suction port of fan 7 faces the paper feeding mechanism 2; the motor 8 is the paper feeding mechanism 2 through the transmission device 9, the gluing mechanism 3, the rubber feeding mechanism 4, the paper The power is provided by the folding mechanism 5 and the finished product output mechanism 6; its working path is to transport the label paper to the gluing mechanism 3 for gluing by the paper feeding mechanism 2; Go to the paper folding mechanism 5 for wrapping, and then output by the finished product output mechanism 6;

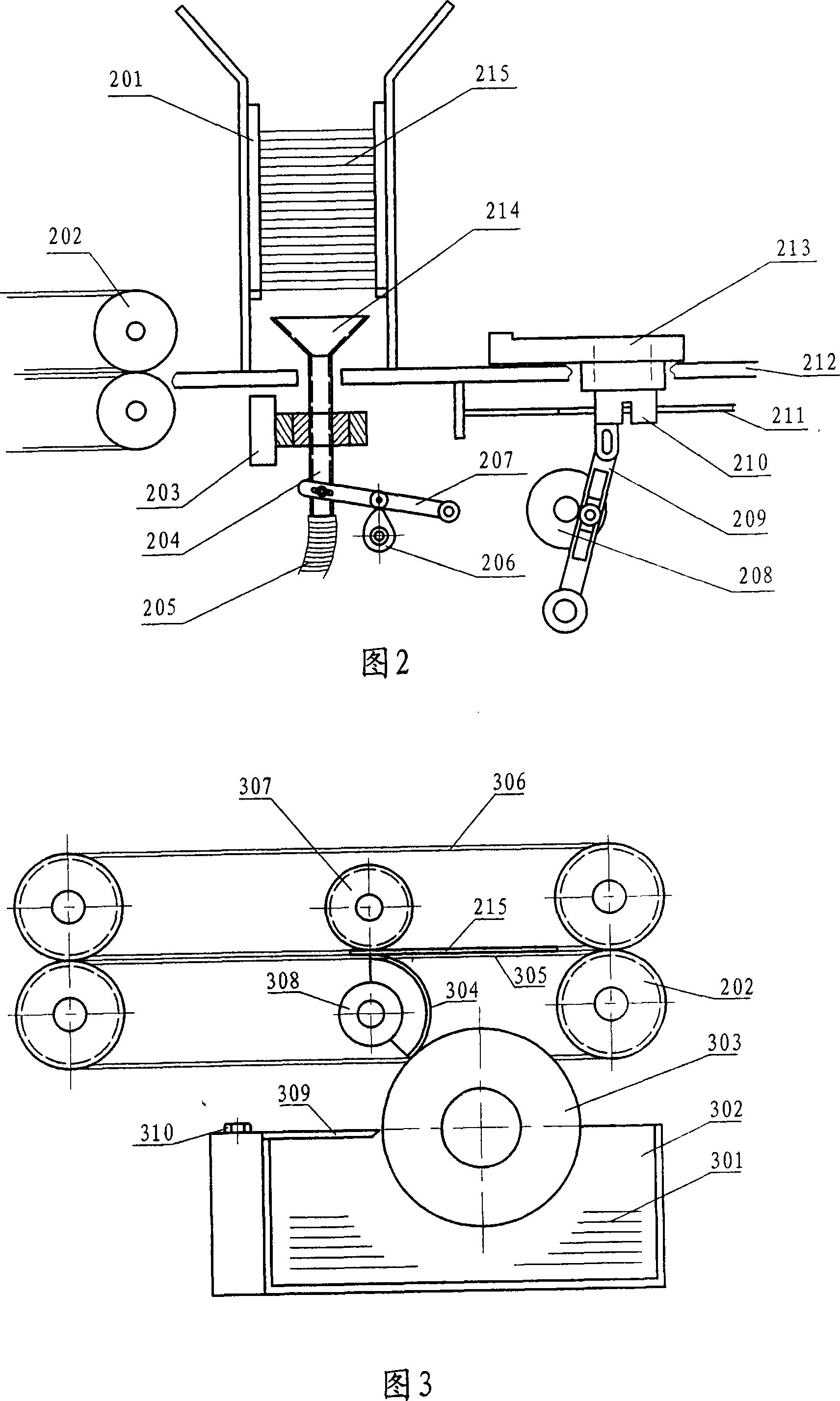

[0021] Said paper feeding mechanism 2, as shown in Figure 2, mainly consists of paper stock b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com