Fermented selenium-enriched coarse-cereals lead removing porridge and preparation method thereof

A miscellaneous grain and selenium-enriched technology, applied in food preparation, bacteria used in food preparation, food science, etc., can solve the problems of low absorption utilization rate, excessive absorption, disadvantages, etc., and achieve easier absorption, easy to carry and eat, good quality The effect of lead removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

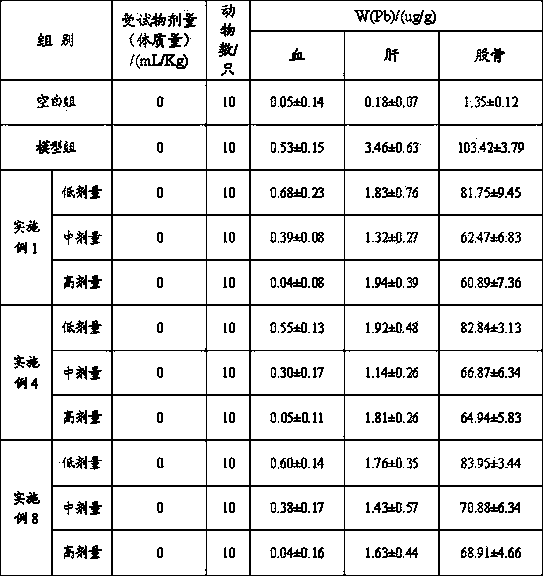

Examples

Embodiment 1

[0059] A fermented selenium-enriched miscellaneous grain porridge for removing lead, which is made of the following raw materials in parts by weight:

[0060] Raw material parts by weight

[0061] Selenium Enriched Rice 35

[0062]Selenium-enriched corn 42

[0063] mung beans 18

[0066] A method for preparing fermented selenium-enriched miscellaneous grains porridge containing lead, the steps of which are:

[0067] A. Pick the ingredients and make them according to a certain weight ratio: selenium-enriched rice, selenium-enriched corn, mung bean, acorn powder, lotus seed powder, wherein the selenium content in the selenium-enriched rice and selenium-enriched corn is 0.15-0.50 mg / Kg, sealed and ripened by water vapor method, cooled for standby;

[0068] B. Add yeast and lactic acid bacteria mixed bacteria solution according to the weight ratio of 50:1, wherein, yeast: lactic acid bacteria is 6:4, the total number of ...

Embodiment 7

[0077] Fermented selenium-enriched miscellaneous grain lead-expelling porridge and a preparation method thereof, the steps of which are as follows:

[0078] A. Pick the ingredients and prepare the composition by weight ratio: 40 parts of selenium-enriched rice, 30 parts of selenium-enriched corn, 20 parts of mung beans, 5 parts of acorn powder, and 15 parts of lotus seed powder, wherein the selenium-enriched rice and selenium-enriched corn The selenium content in the medium is 0.15~0.50mg / Kg, sealed and matured by steam method, cooled for later use;

[0079] B. Add yeast and lactic acid bacteria mixed bacteria liquid at a weight ratio of 20:1, wherein, yeast: lactic acid bacteria is 8:2, and the total number of effective viable bacteria: 8.41×10 10 per mL, the fermentation temperature was 35°C, the fermentation time was 24 hours, and the humidity of the fermentation environment was 90%.

[0080] C, after the above-mentioned fermentation is completed, add 10 parts by weight of...

Embodiment 8

[0085] A. Pick the ingredients and prepare the composition by weight ratio: 20 parts of selenium-enriched rice, 30 parts of selenium-enriched corn, 10 parts of mung beans, 10 parts of acorn powder, and 30 parts of lotus seed powder, wherein the selenium-enriched rice and selenium-enriched corn The selenium content in the medium is 0.15~0.50mg / Kg, sealed and matured by steam method, cooled for later use;

[0086] B. Add yeast and lactic acid bacteria mixed bacteria solution at a weight ratio of 40:1, wherein the ratio of yeast and lactic acid bacteria mixed bacteria solution is 6:4 to 8:2, and the total number of effective viable bacteria in the bacteria solution is 8.87×10 10 per mL, the fermentation temperature was 30°C, the fermentation time was 48h, and the humidity of the fermentation environment was 95%.

[0087] C, after the above-mentioned fermentation is completed, add low-temperature superfine edible rapeseed pollen and buckwheat pollen in 2 parts by weight, and adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com