Micro swing type monopropellant engine

A pendulum engine, a single component technology, applied in the direction of the swing piston engine, rotary or swing piston engine, engine components, etc., can solve the lack of hydrogen peroxide catalytic device, distribution valve exhaust valve and pendulum engine, structure Sexual issues have not received attention and other issues, and achieve the effect of simple and reliable structure, low noise, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

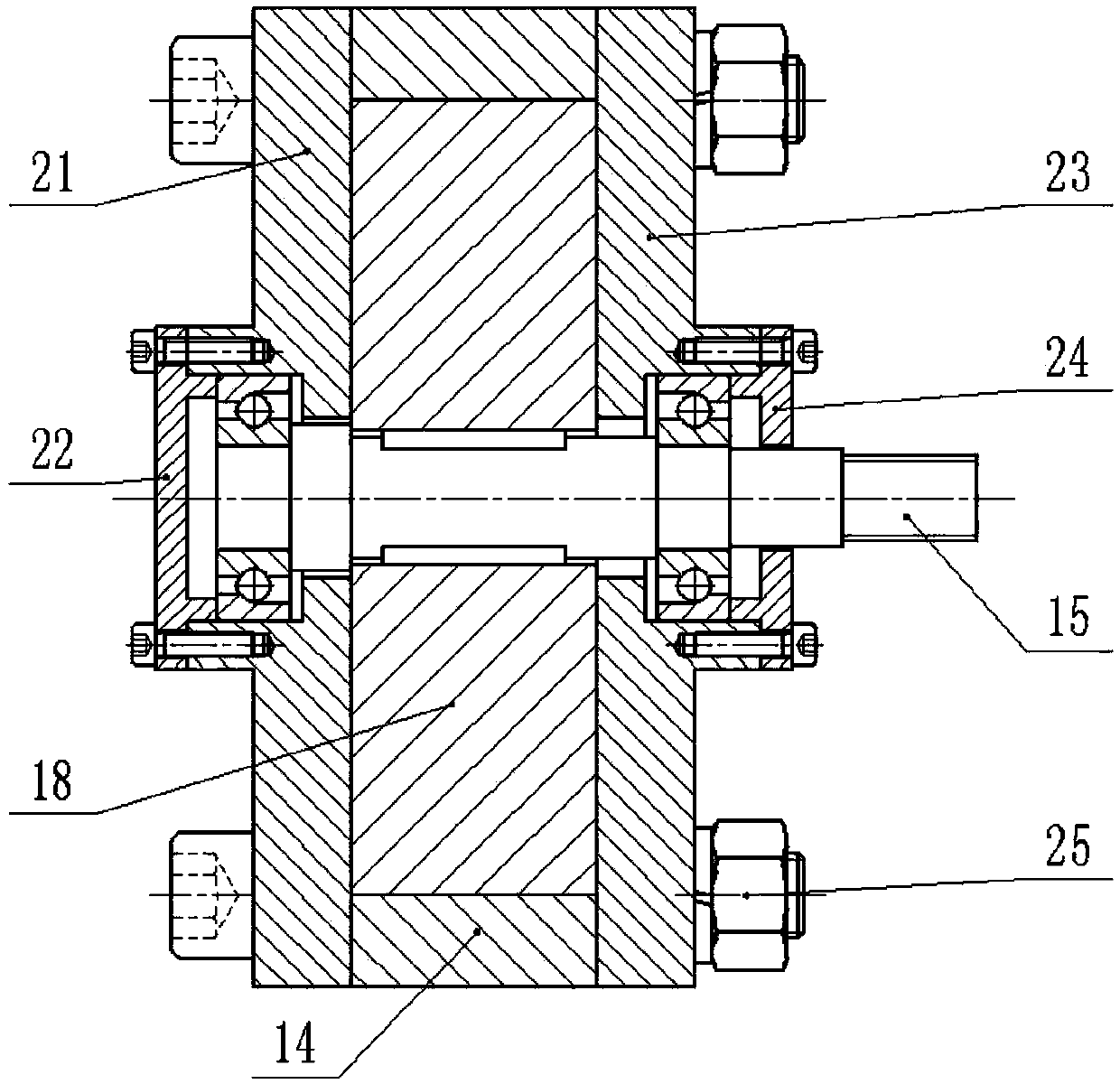

[0029] figure 1 It shows the system working principle of the miniature pendulum single-element engine disclosed in the present invention. The miniature pendulum single-component engine includes a single-component fuel tank 1, a pendulum engine 8, a fuel distribution valve 12, a catalytic device 6, an angle sensor 10, and an electronic control unit (ECU) 5. The upper side of the fuel tank 1 is provided with a fuel filling port 2, a high-speed solenoid valve 3 and a pressure gauge 4. The lower outlet end is provided with a fuel emergency discharge valve 13 and a fuel distribution valve 12. The outlet ends of the fuel distribution valve 12 are connected to each other through a pipe. The catalytic devices 6 on the left and right sides of the cylinder 14 of the pendulum engine 8 are connected. The output of the pressure sensor in the pressure gauge 4 is connected to the corresponding inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com