Preparation method for hyaluronic acid functionalized nano fibers applied to capturing cancer cells in targeted manner

A technology of nanofibers, hyaluronic acid, applied in the direction of biochemical equipment and methods, fiber types, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Weigh 9.68732g of PVA, dissolve it in 71.04g of ultrapure water, stir slowly with a glass rod for about 30 minutes until the PVA powder is completely swollen, then place it on a magnetic stirrer and heat and stir in a water bath at 80°C for 3 hours to obtain a uniform concentration of 12wt% PVA solution.

[0066] Take by weighing the PVA spinning solution of 12wt% that 15g has configured, wherein the amount of PVA is 1.8g, according to the mass ratio of PVA and PEI solid in the mixed solution of setting is 3:1, thereby draw the quality of required PEI as 0.6g, weigh 0.6g PEI and add it to 15g12wt% PVA spinning solution, continue to add 4.4g water, mix it with a vortex mixer, then use ultrasound for 30min to disperse it evenly, stir it overnight with a magnetic force, and get the spinning solution PVA / PEI The total mass percentage concentration is 12wt%.

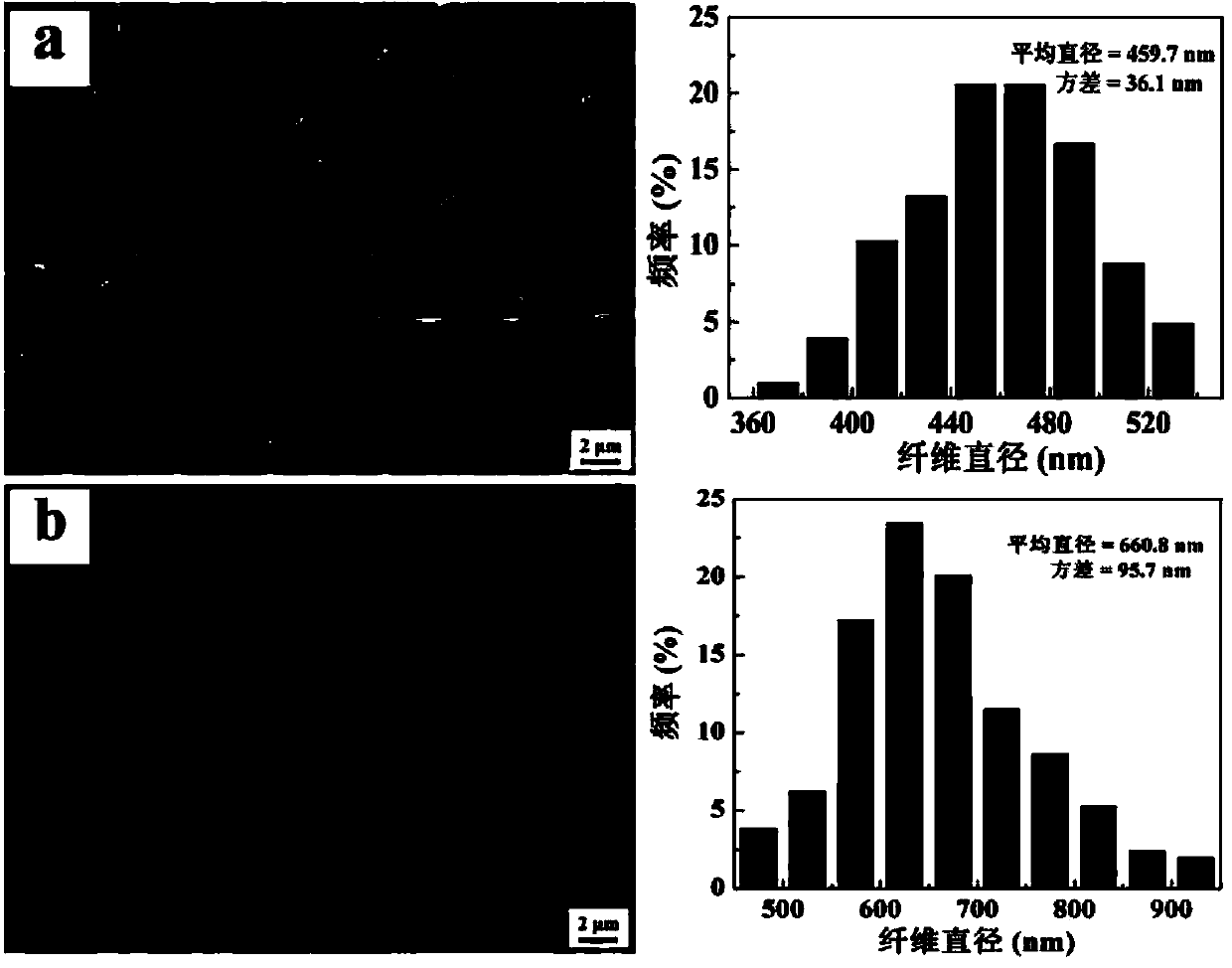

[0067] The spinning process conditions used are: the spinning voltage is 18.6kV, of which the positive pressure is ...

Embodiment 2

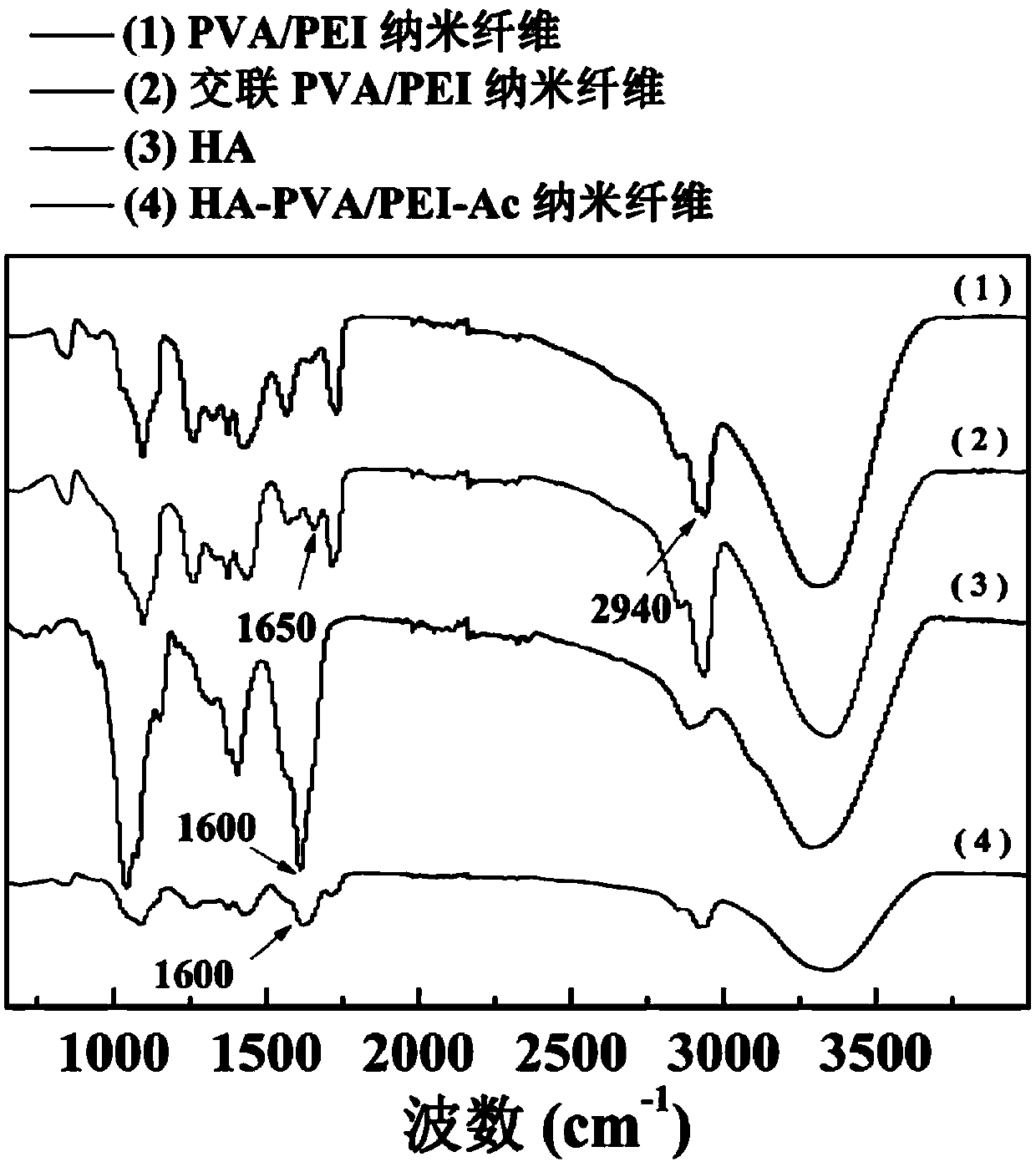

[0070] Put the PVA / PEI nanofiber mat prepared in Example 1 above the petri dish filled with 25% glutaraldehyde solution, put the two together in a desiccator, and vacuumize and crosslink for 18 hours. The appearance of the obtained PVA / PEI nanofibers was pink. After soaking the glutaraldehyde-crosslinked nanofibers in the aqueous solution for 7 days, the SEM results showed that the fiber morphology remained good, there was no adhesion phenomenon, and the average fiber diameter increased to 660.8± 95.7nm (with figure 1 b), showing that the fiber has good water stability.

Embodiment 3

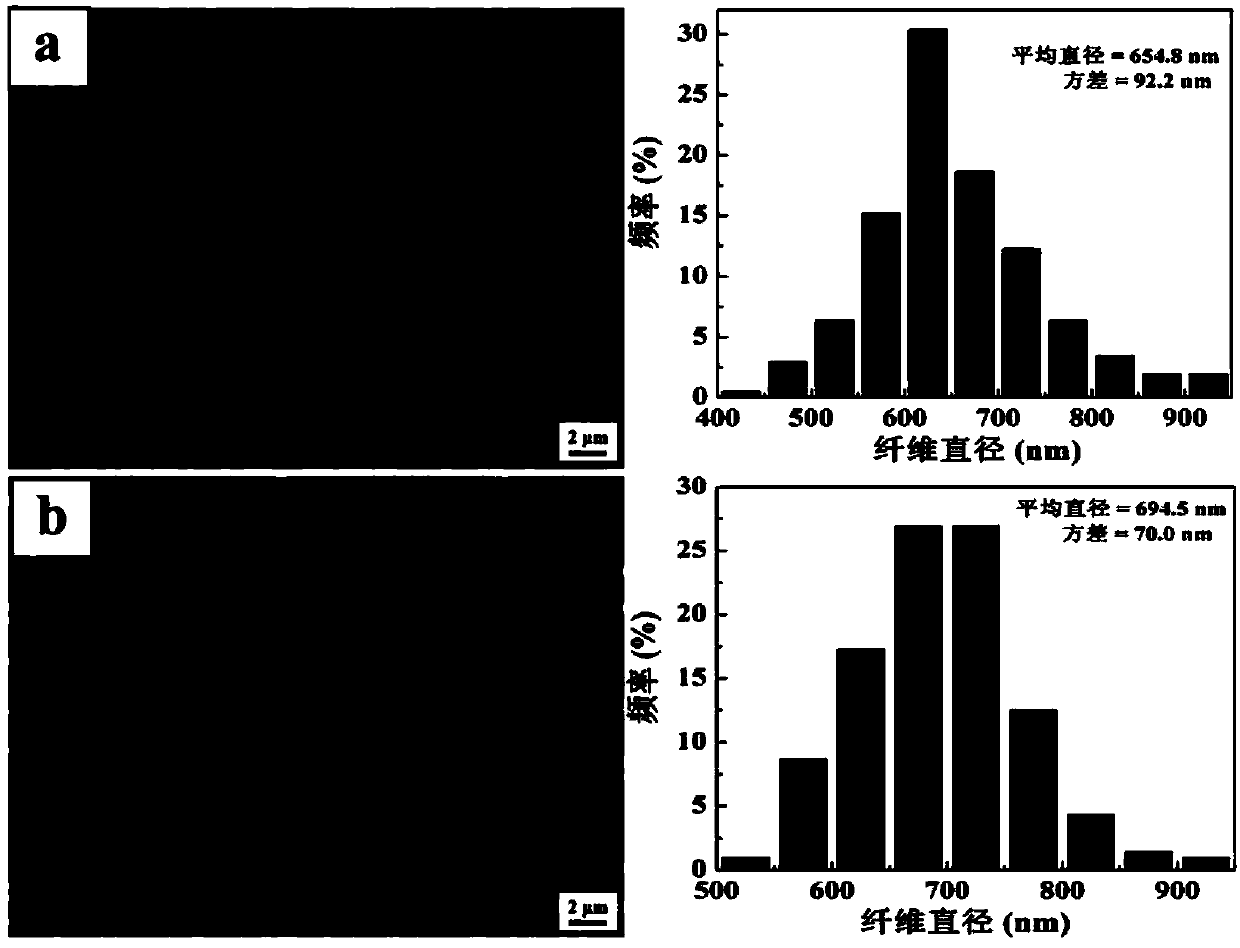

[0072] The mass of PVA / PEI nanofibers was weighed to be 120.4 mg, and the mass ratio of PVA:PEI=3:1 was calculated to obtain that the mass of PEI was 30.1 mg. According to the primary amine (R-NH 2 ) 1.08mol, secondary amine (R 2 -NH) 1.49mol, tertiary amine (R 3 -N) 1 mol, of which only primary and secondary amines can participate in the amidation reaction. Therefore, in the 120.4 mg fiber membrane, the amino group that can participate in the amidation reaction is 0.563 mol. Based on the molar ratio of carboxyl:amino = 1:1, the required HA is 0.563mol and the mass is 213.94mg. Calculated based on the molar ratio HA:EDC:NHS=1:5:5, the amount of EDC is 539.64 mg, and the amount of NHS is 323.98 mg, which are respectively dissolved in 10 mL of water and slowly added dropwise to 10 mL of aqueous solution containing 213.94 mg of HA, thereby The activation reaction was carried out with a reaction system with a total volume of 30 mL for 3 h, 30 mL of HA reaction solution was add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com