Preparation method of gas diffusion electrode for producing formic acid by electrochemical reduction of CO2

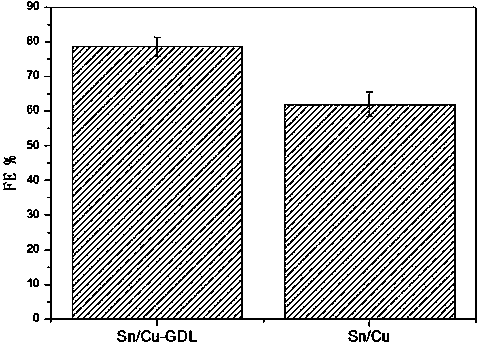

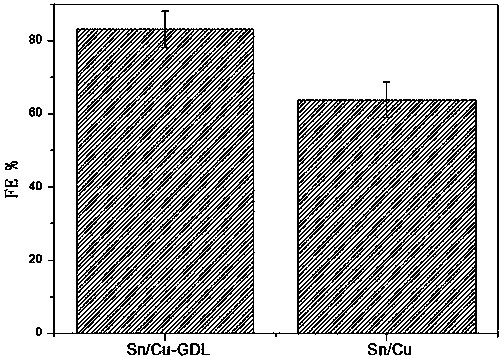

A gas diffusion electrode, electrochemical technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of low solubility, mass transfer rate inhibiting electrochemical reduction efficiency, and restricting the development and application of electrochemical reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

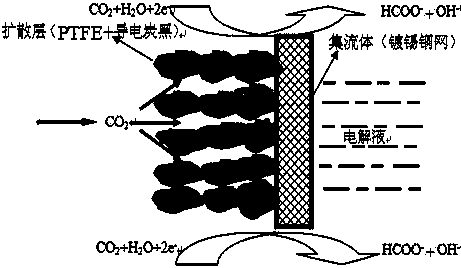

[0026] An electrochemical reduction of CO 2 The preparation method of the gas diffusion electrode of formic acid, the steps are as follows:

[0027] 1) Add 0.9g of powdered conductive carbon black to 80mL of absolute ethanol until completely submerged and dispersed evenly. After ultrasonic stirring at room temperature for 20 minutes, add 2.1g of 60wt% polytetrafluoroethylene (PTFE) emulsion dropwise, and continue ultrasonic stirring for 20 minutes. , the resulting mixture was subjected to 80 o C water bath and stir until it forms a mass, then roll it into a film to obtain a diffusion layer film;

[0028] 2) After the 60-80 mesh copper mesh is degreased, washed with water, pickled with 10wt% dilute hydrochloric acid, and washed with water, it is put into the chemical tin plating solution. The chemical tin plating solution is a mixture of stannous sulfate, sulfuric acid and thiourea. Mixed solution, the concentrations of stannous sulfate, sulfuric acid and thiourea in the mixe...

Embodiment 2

[0035] An electrochemical reduction of CO 2 The preparation method of the gas diffusion electrode of formic acid, the steps are as follows:

[0036] 1) Add 0.9g of powdered conductive carbon black to 80mL of absolute ethanol until completely submerged and dispersed evenly. After ultrasonic stirring at room temperature for 20 minutes, add 2.1g of 60wt% polytetrafluoroethylene (PTFE) emulsion dropwise, and continue ultrasonic stirring for 20 minutes. , the resulting mixture was subjected to 80 o C water bath and stir until it forms a mass, then roll it into a film to obtain a diffusion layer film;

[0037] 2) After degreasing, washing with water, pickling with 10wt% dilute hydrochloric acid, and pretreatment with water, put the 60-80 mesh copper mesh into the electroplating tin bath, which is the mixture of stannous chloride, sodium citrate and hydrochloric acid Mixed solution, the concentrations of stannous chloride, sodium citrate and hydrochloric acid in the mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com