Ganoderma applanatum polysaccharide preparation method

A technology of Ganoderma lucidum and Ganoderma lucidum powder, applied in fermentation and other directions, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of ganoderma ganoderma polysaccharide, the innovation of the present invention is: comprise the following steps:

[0028] (1) Uniformly mix the Ganoderma lucidum powder with the solid medium;

[0029] (2) Cultivate the product of step (1) at a constant temperature of 35-37 degrees Celsius for 24-48 hours;

[0030] (3) Centrifuge the fermented mycelium and wash it with distilled water for 2 to 3 times;

[0031] (4) Put the cleaned mycelium into a drying box, and dry it at 45-60 degrees Celsius to obtain the finished product.

[0032] Wherein, 150-200 grams of ganoderma ganoderma powder is added to each liter of the solid medium.

[0033] Each liter of said solid medium includes:

[0034] Mushroom bran 200-400 grams

[0035] Glucose 5-15 grams

[0036] Sodium dihydrogen phosphate 0.2~1.0 g

[0037] Potassium chloride 0.5~1.0 g

[0038] Vitamin B1 5~10 ml

[0039] Peptone 5-8 grams

[0040] The balance is water

[0041] After each com...

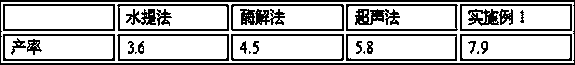

Embodiment 1

[0043] (1) Evenly mix 150 grams of Ganoderma lucidum powder with 1 liter of solid medium;

[0044] Solid media are:

[0045] Shiitake mushroom chaff 200 g

[0046] Glucose 5 g

[0047] Sodium dihydrogen phosphate 0.2 g

[0048] Potassium chloride 0.5 g

[0049] Vitamin B1 5 ml

[0050] Peptone 5 g

[0051] The balance is water

[0052] After each component is blended, it is autoclaved for 30 minutes under the condition of 0.1MPa.

[0053] (2) Cultivate the product of step (1) at a constant temperature of 35 degrees Celsius for 24 hours;

[0054] (3) Centrifuge the fermented mycelium at 800-1500 rpm, and wash it with distilled water for 3 times;

[0055] (4) Put the cleaned mycelium into a drying box, and dry it at 45 degrees Celsius to obtain a finished product.

[0056]

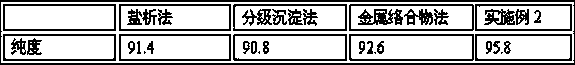

Embodiment 2

[0058] (1) Evenly mix 200 grams of Ganoderma lucidum powder with 1 liter of solid medium;

[0059] Solid media are:

[0060] Shiitake mushroom chaff 400 g

[0061] Glucose 15 g

[0062] Monosodium Phosphate 1.0 g

[0063] Potassium chloride 1.0 g

[0064] Vitamin B1 10ml

[0065] Peptone 8 g

[0066] The balance is water

[0067] After each component is blended, it is autoclaved for 30 minutes under the condition of 0.1MPa.

[0068] (2) Cultivate the product of step (1) at a constant temperature of 35 degrees Celsius for 24 hours;

[0069] (3) Centrifuge the fermented mycelium at 800-1500 rpm, and wash it twice with distilled water;

[0070] (4) Put the cleaned mycelium into a drying box, and dry it at 45 degrees Celsius to obtain a finished product.

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com