Low-energy-consumption degradation-resistant organic wastewater recycling method

An organic wastewater, refractory technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult removal of toxic compounds, high chromaticity and high concentration of wastewater , to achieve the effect of improving biodegradability, alleviating membrane fouling, and good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

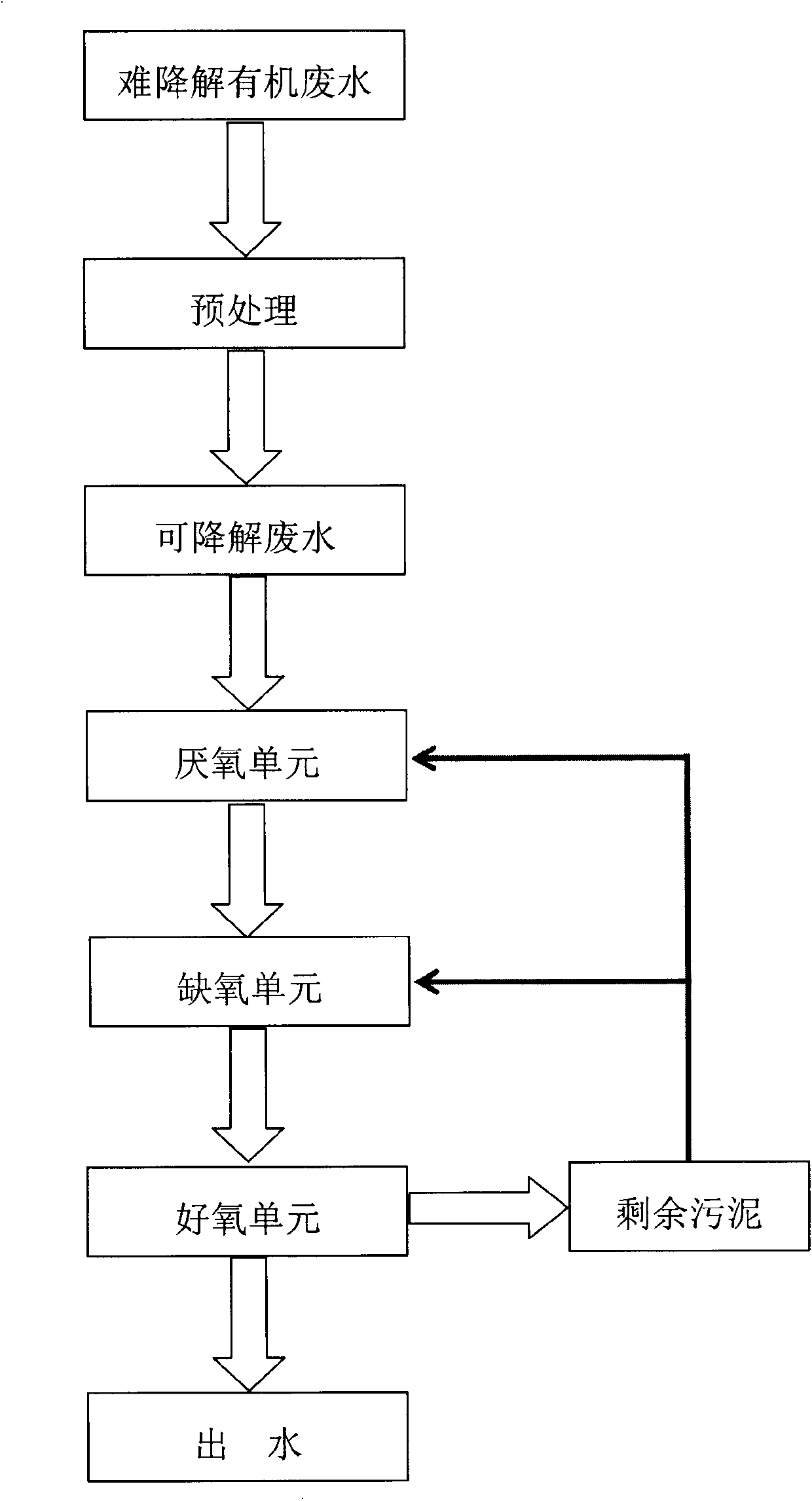

Image

Examples

Embodiment 1

[0030] Example 1: The MFC anode uses carbon felt, and the MBR membrane module uses graphene + polyvinylidene fluoride modified non-woven fabric. The water quality of the system influent is as follows: COD concentration is 1000mg / L, ammonia nitrogen is 100mg / L, pH value is 8, B / C ratio is 0.2; pretreatment adopts hydrolytic acidification method, HRT is 12h; The HRT of the oxygen unit is 10h, and the dissolved oxygen concentration is 0.2mg / L; the HRT of the aerobic unit is 6h, and the dissolved oxygen concentration is 4.0mg / L; the temperature is 25°C.

Embodiment 2

[0031]Example 2: The MFC anode is made of carbon cloth, and the MBR membrane module is made of polyaniline-modified stainless steel mesh. The system influent water quality is as follows: COD concentration is 5000mg / L, ammonia nitrogen is 1000mg / L, pH value is 3, B / C ratio is 0.1; Fenton oxidation method is used for pretreatment, HRT is 0.5h, and the pH value is adjusted to 7.0; The HRT of the oxygen unit is 24h; the HRT of the anoxic unit is 12h, and the dissolved oxygen concentration is 0.5mg / L; the HRT of the aerobic unit is 8h, and the dissolved oxygen concentration is 2.0mg / L; the temperature is 30°C.

Embodiment 3

[0032] Example 3: The MFC anode uses graphite, and the MBR membrane module uses graphene-modified carbon cloth. The system influent water quality is as follows: COD concentration is 10000mg / L, ammonia nitrogen is 2000mg / L, pH value is 12, B / C ratio is 0.1; electrolysis is used for pretreatment, HRT is 0.5h, pH value is adjusted to 7.0; anaerobic unit The HRT of the anoxic unit is 30h; the HRT of the anoxic unit is 20h, and the dissolved oxygen concentration is 0.1mg / L; the HRT of the aerobic unit is 12h, and the dissolved oxygen concentration is 6.0mg / L; the temperature is 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com