Welding method of aero-engine high-energy ignition device

An aero-engine, high-energy ignition technology, applied in welding equipment, liquid chemical plating, coating, etc., to achieve the effects of easy operation, guaranteed work reliability, and guaranteed shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

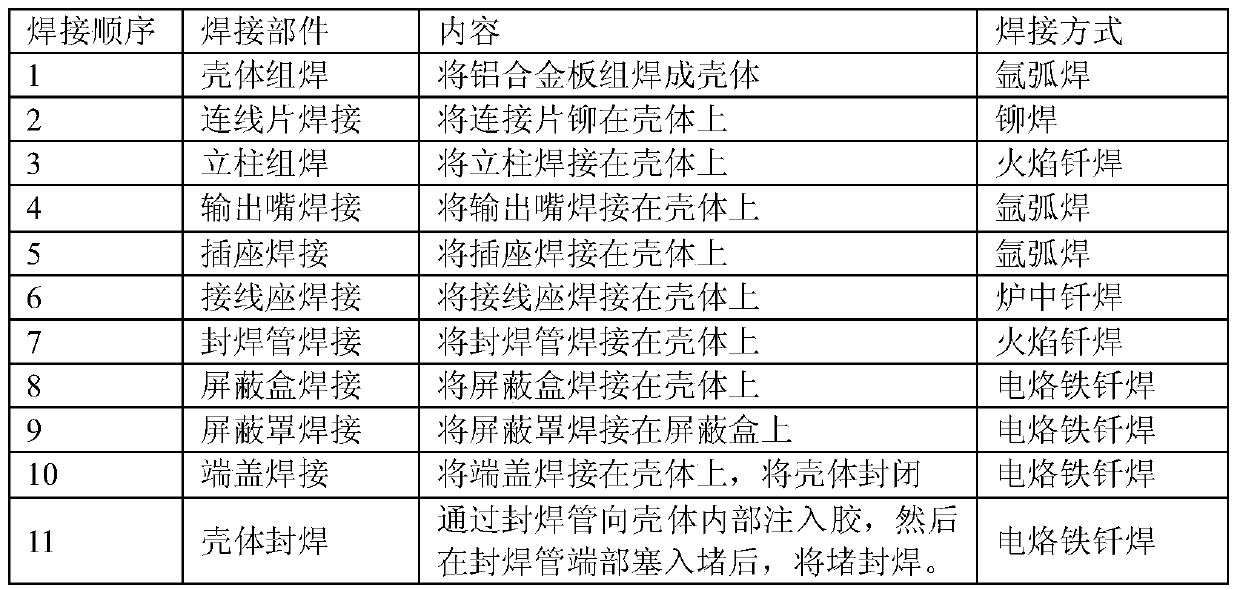

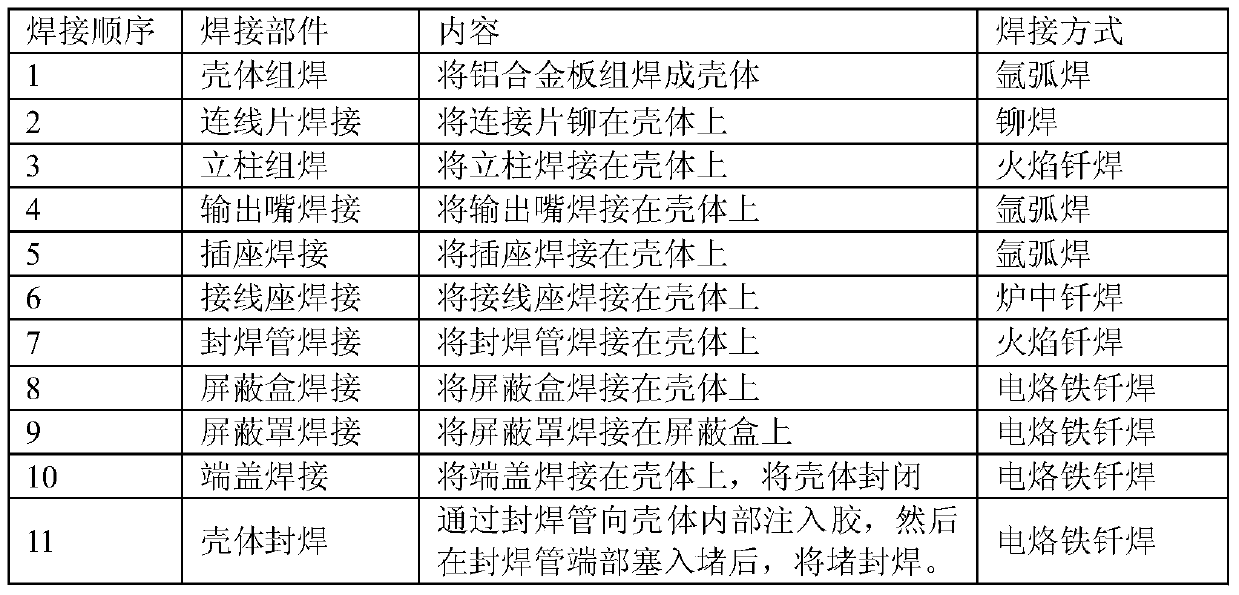

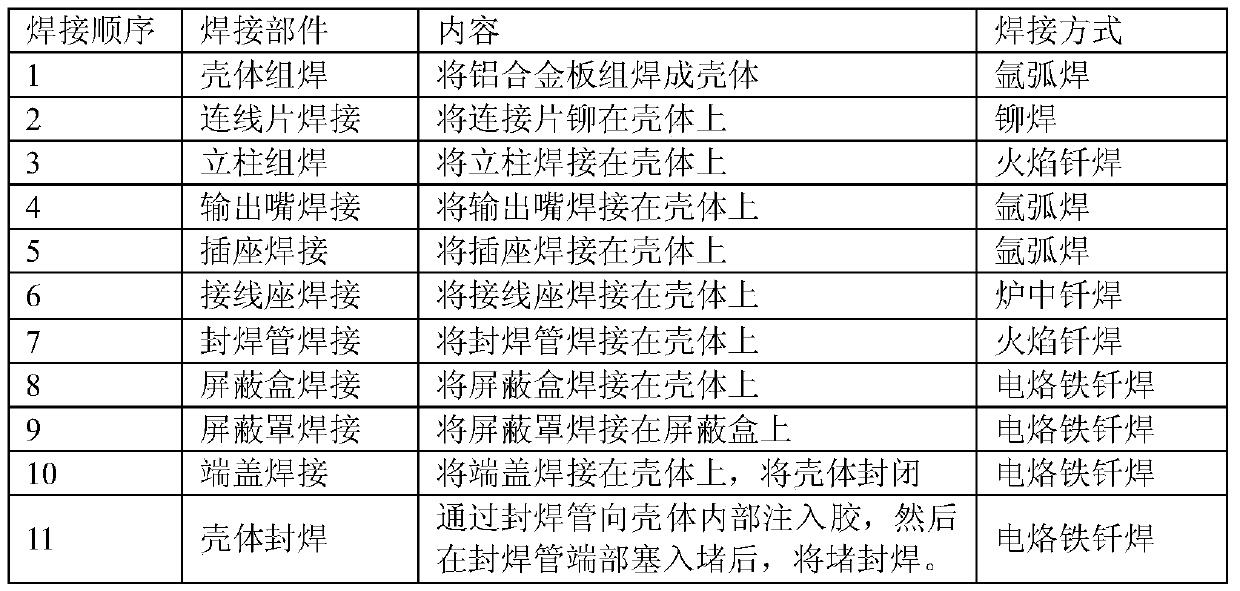

[0041] An aircraft high-energy ignition device, the product model is DHZ-119, the specific steps of welding are as follows:

[0042] 1) Electroless nickel plating is performed on the surface of all aluminum alloy parts that require tin brazing, and the surface electroless nickel plating is carried out according to the following steps:

[0043] a) Cleaning: Soak the parts in No. 180 gasoline for 10 minutes, take them out, clean them with a clean soft brush and dry them naturally;

[0044] b) Chemical degreasing: Soak the parts in a solution of 10 g / L, 18 g / L sodium phosphate, 31 g / L sodium silicate, 24 g / L sodium carbonate, and the rest of water for 3 minutes. The temperature is 70°C;

[0045] c) Alkali etching: Put the parts into a solution whose composition is 60 g / l of sodium hydroxide and the rest is water for 0.8 minutes, and the immersion temperature is 60°C;

[0046] d) Acid etching: put the parts into a solution whose composition is 500 ml / liter of nitric acid and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com