Cleaning spraying nozzle and cleaning method for high pressure cleaner

A technology for high-pressure cleaners and cleaning nozzles, applied to liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of short spray hole depth, affecting cleaning effect, and large water outlet angle, etc., to achieve Good cleaning effect, improve cleaning efficiency and reduce rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

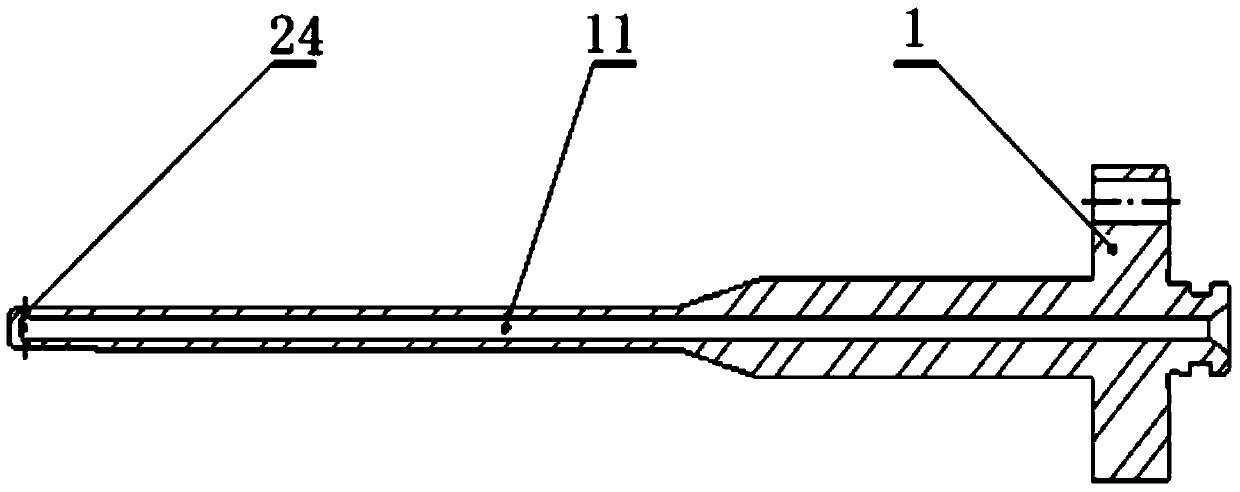

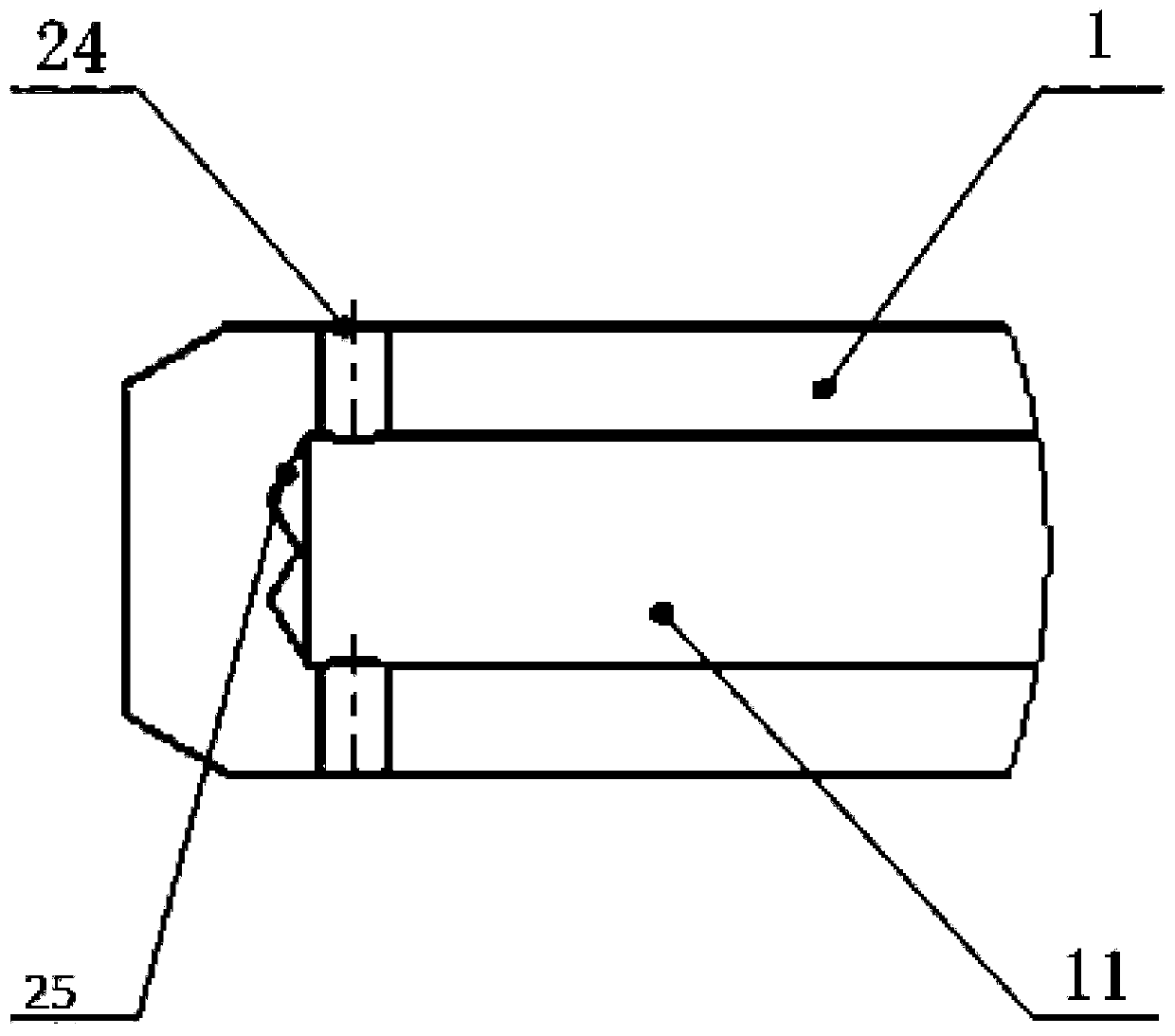

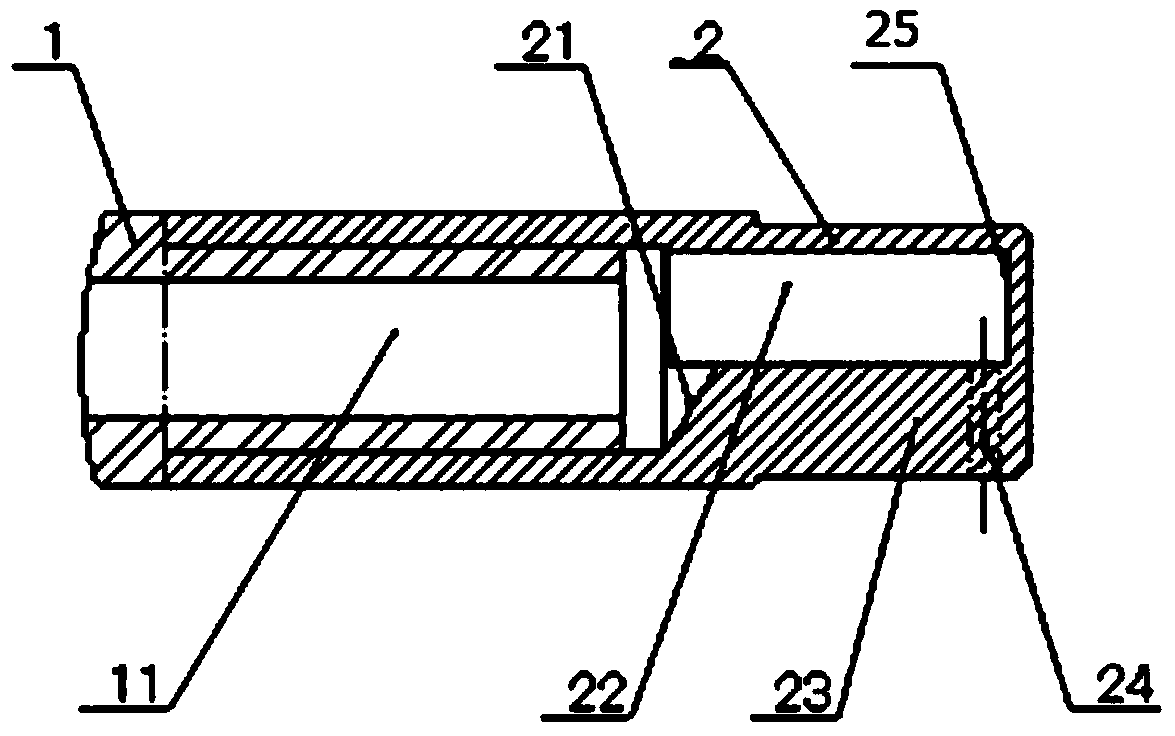

[0020] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0021] The invention relates to a cleaning nozzle, in particular to a nozzle for rotating and cleaning deep holes for a high-pressure cleaning machine. The nozzle mainly includes a nozzle head main body, and the nozzle head main body has two injection holes and two guide grooves. The injection hole communicates with the guide groove. The injection hole is perpendicular to the diversion groove and the depth of the injection hole is lengthened to 2.5-3.3mm. Both diversion grooves are fan-shaped structures. The cross-sectional area of a single fan-shaped diversion groove is about 1 / 2 of the cross-sectional area of the diversion ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com