Beneficiation method for high-grade copper-nickel sulphide ore

A technology of copper-nickel sulfide and beneficiation method, which is applied to the beneficiation of nickel sulfide ore, copper sulfide and nickel associated ore, and the field of copper sulfide ore, which can solve the problems of complex process flow, low recovery rate of copper-nickel metal, and large one-time investment. , to achieve the effect of advanced technology and reduction of tailings metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below using the accompanying drawings and specific examples.

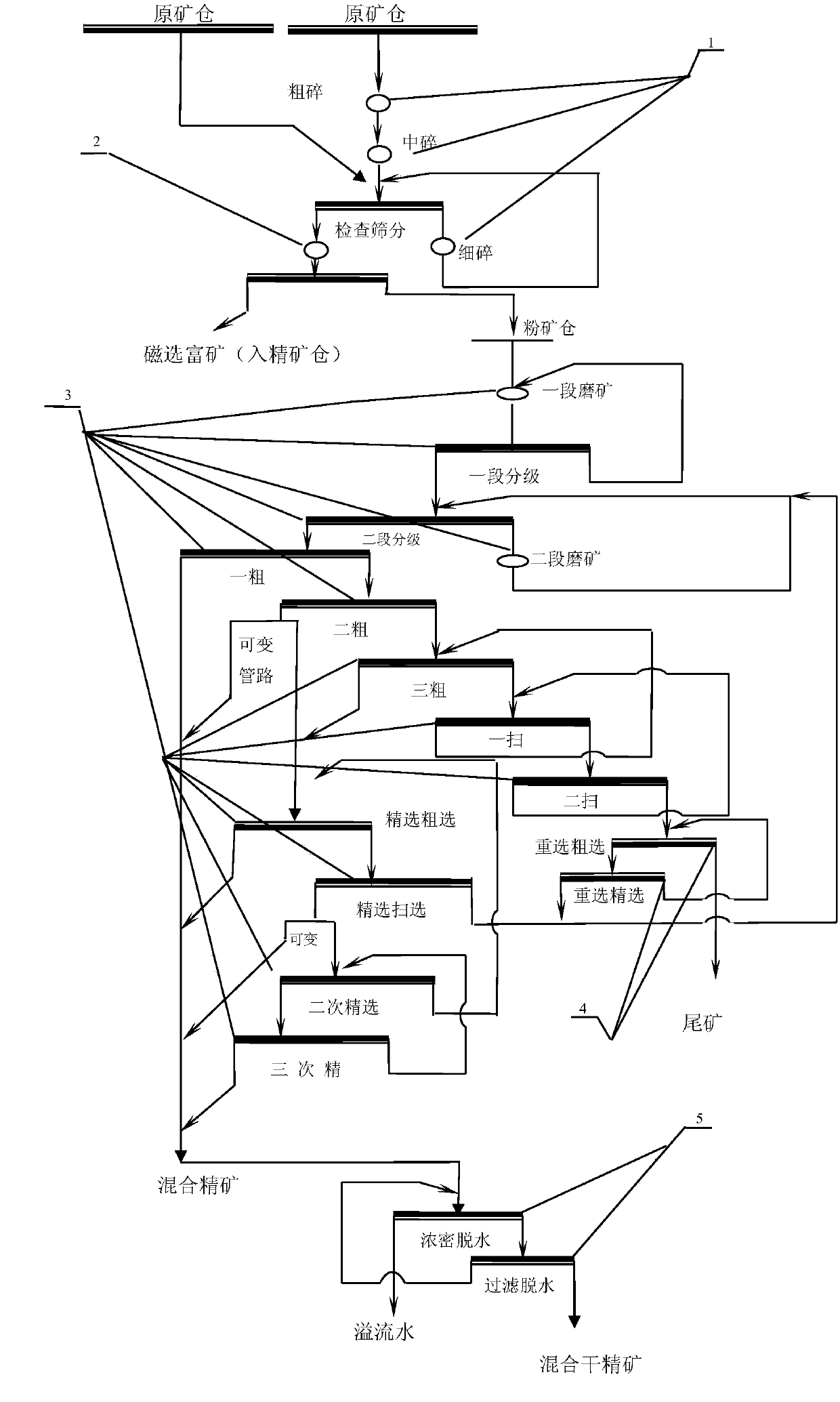

[0036] With reference to accompanying drawing, a kind of beneficiation method of high-grade copper-nickel sulfide ore comprises the following steps successively:

[0037] That is, the crushing and screening of raw ore, magnetic separation pre-selection of raw ore, grinding and flotation of low-grade ore, and the treatment process of concentration and filtration of flotation concentrate, as follows

[0038]Raw ore crushing and screening process 1. The original dressing plant adopts a three-stage and one closed-circuit crushing process. On this basis, a new ore bin is built near the ore raw ore bin, and the ore from the new ore bin is introduced into the third stage by using a plate feeder and a belt conveyor. A closed-circuit process inspection screening place. Due to the soft nature of copper and nickel minerals, especially the high-grade copper-nickel ore has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com