Preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping

A fiber reinforced concrete and ultra-high-strength steel technology, applied in the field of building materials, can solve the problems of low viscosity and strength not reaching the C120 strength level, and achieve the effects of low viscosity, optimized mixing ratio, and improved crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

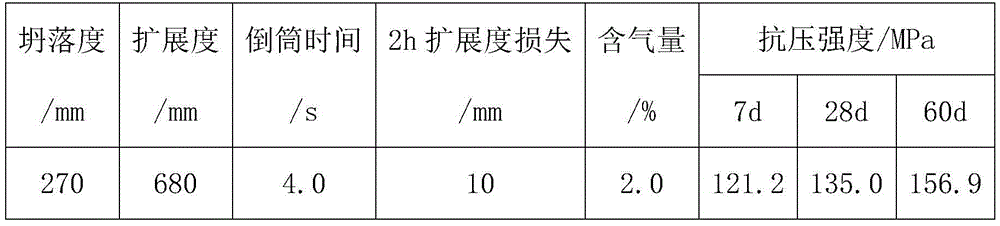

[0028] The ultra-high pumping ultra-high-strength steel fiber concrete prepared in this embodiment, the raw material ratio (1m 3 Concrete material consumption) as shown in Table 1:

[0029]Table 1: C150 ultra-high-strength steel fiber reinforced concrete mix design (kg / m 3 )

[0030] cement

microbeads

mineral powder

steel fiber

mixing water

450

300

120

130

550

760

80

150

20

[0031] Step 1: Mix and stir river sand and basalt particles evenly for 30 seconds to obtain a mixture;

[0032] Step 2: mix the mixture obtained in step 1 with cement, mineral admixtures, and 80% mixing water for 60 seconds, and stir evenly; the weight of the cement is 34.35% of the aggregate weight, and the mineral admixture The weight of material is 41.98% of aggregate weight, and the weight of described 80% mixing water is 9.16% of aggregate weight; Described aggrega...

Embodiment 2

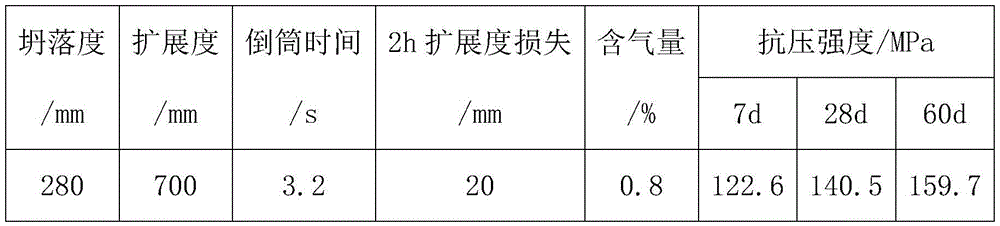

[0040] The ultra-high pumping ultra-high-strength steel fiber concrete prepared in this embodiment, the raw material ratio (1m 3 Concrete material consumption) as shown in Table 3:

[0041] Table 3: C150 ultra-high-strength steel fiber reinforced concrete mix design (kg / m 3 )

[0042] cement

microbeads

mineral powder

steel fiber

mixing water

500

200

220

80

660

660

120

150

22

[0043] Step 1: Mix and stir river sand and basalt particles evenly for 30 seconds to obtain a mixture;

[0044] Step 2: Mix the mixture obtained in step 1 with cement, mineral admixtures, and 80% mixing water for 60 seconds, and stir evenly; the weight of the cement is 37.88% of the aggregate weight, and the mineral admixture The weight of material is 37.88% of aggregate weight, and the weight of described 80% mixing water is 9.09% of aggregate weight; Described aggreg...

Embodiment 3

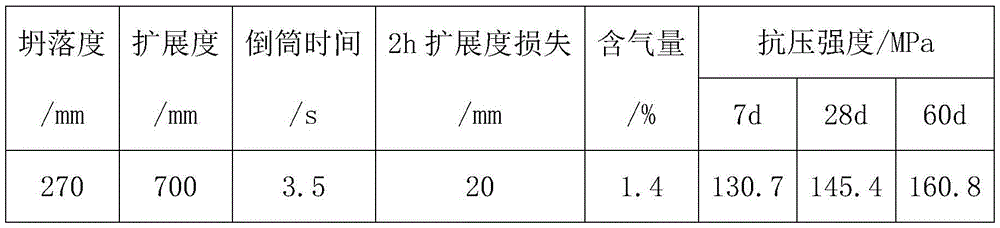

[0052] The ultra-high pumping ultra-high-strength steel fiber concrete prepared in this embodiment, the raw material ratio (1m 3 Concrete material consumption) as shown in Table 5:

[0053] Table 5: C150 ultra-high-strength steel fiber reinforced concrete mix design (kg / m 3 )

[0054] cement

microbeads

mineral powder

river sand

steel fiber

mixing water

580

200

170

50

600

680

140

150

21

[0055] Step 1: Mix and stir river sand and basalt particles evenly for 30 seconds to obtain a mixture;

[0056] Step 2: mix the mixture obtained in step 1 with cement, mineral admixtures, and 80% mixing water for 60 seconds, and stir evenly; the weight of the cement is 45.31% of the aggregate weight, and the mineral admixture The weight of material is 32.81% of aggregate weight, and the weight of described 80% mixing water is 9.38% of aggregate weight; Described aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com