Lutein ester microcapsule and preparation method thereof

A technology of lutein ester and microcapsule, applied in the field of lutein ester microcapsule and preparation thereof, can solve the problems of complex production operation, low safety and high production cost, and achieve high commercial value, high safety and stability saved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

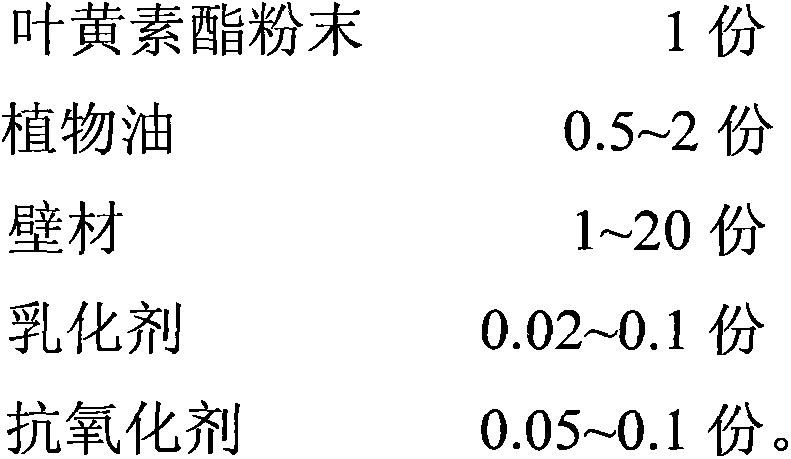

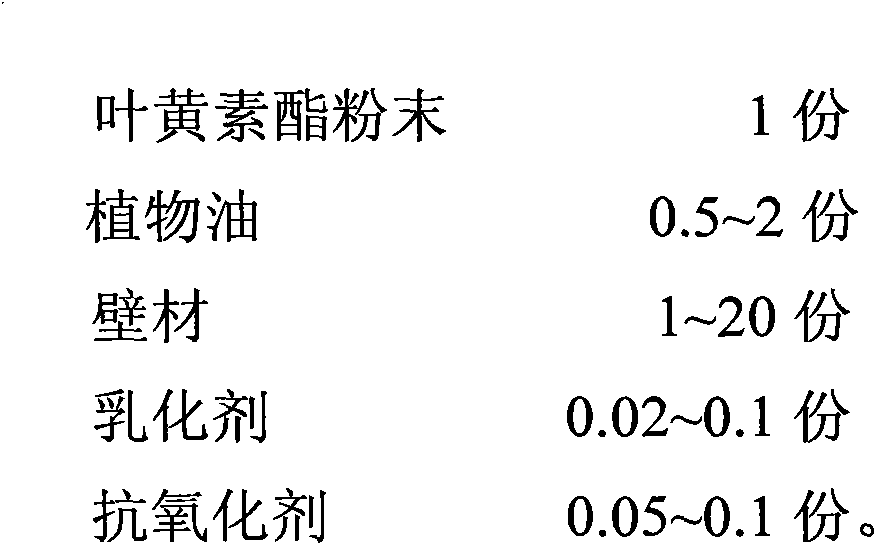

Method used

Image

Examples

Embodiment 1

[0023] Weigh 100 g of lutein ester powder (content: 57%) and place it in a beaker, add 50 g of corn germ oil therein, place it in a water bath at 50° C. and stir and heat for 30 minutes to completely dissolve the lutein ester powder to obtain lutein Vegetarian oil phase. Weigh 500 g of modified starch and 200 g of maltodextrin, and dissolve them in 1000 mL of distilled water to prepare a wall material solution. Add the mixed core material into the wall material solution, add 2g of emulsifier (Span: Tween = 1:1) and 5g of vitamin C at the same time, mix at 60°C for 30min to form colostrum, and then press the colostrum under 30Mpa pressure Homogenize 3 times to form a stable emulsion. The emulsion was spray-dried and granulated, and the spray-drying conditions were as follows: the inlet air temperature was 160°C, and the feeding speed was 10mL / min to obtain lutein ester microcapsules.

Embodiment 2

[0025] Weigh 50 g of lutein ester powder (content: 67%) and place it in a beaker, add 50 g of soybean oil to it, place in a water bath at 60° C. and stir and heat for 60 minutes to completely dissolve the lutein ester powder to obtain lutein Ester oil phase. Weigh 500 g of modified starch and 500 g of maltooligosaccharide, dissolve them in 1500 mL of distilled water to prepare a wall material solution. Add the mixed core material into the wall material solution, add 2g of emulsifier (propylene glycol fatty acid ester: Tween = 1:1) and 3g of vitamin E at the same time, mix at 65°C for 30min to form colostrum, and then put the colostrum under a pressure of 35Mpa Homogenize twice under high pressure to form a stable emulsion. The emulsion was spray-dried and granulated, and the spray-drying conditions were as follows: the inlet air temperature was 170°C, and the feeding speed was 20mL / min to obtain lutein ester microcapsules.

Embodiment 3

[0027] Weigh 100g of lutein ester powder (content is 57%) and put it in a beaker, add 100g of vegetable oil (corn germ oil: peanut oil=1:1), place it in a water bath at 60°C and stir for 40min to make the lutein yellow. The lutein ester powder is completely dissolved to obtain the lutein ester oil phase. Weigh 100 g of gum arabic, 200 g of modified starch, and 500 g of maltodextrin, and dissolve them in 1500 mL of distilled water to prepare a wall material solution. Add the mixed core material into the wall material solution, add 2g of emulsifier (propylene glycol fatty acid ester: lecithin = 1:1) and 5g of sodium ascorbate at the same time, mix at 70°C for 30min to form colostrum, and then put the colostrum under a pressure of 40Mpa Homogenize once under high pressure to form a stable emulsion. The emulsion was spray-dried and granulated, and the spray-drying conditions were as follows: the inlet air temperature was 165°C, and the feeding speed was 15mL / min to obtain lutein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com