Graphic article

A product and film layer technology, applied in the direction of layered products, duplication/marking methods, synthetic resin layered products, etc., can solve the problem of difficult imaging of polyolefin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 11

[0071] *Example 11 using CAB3b

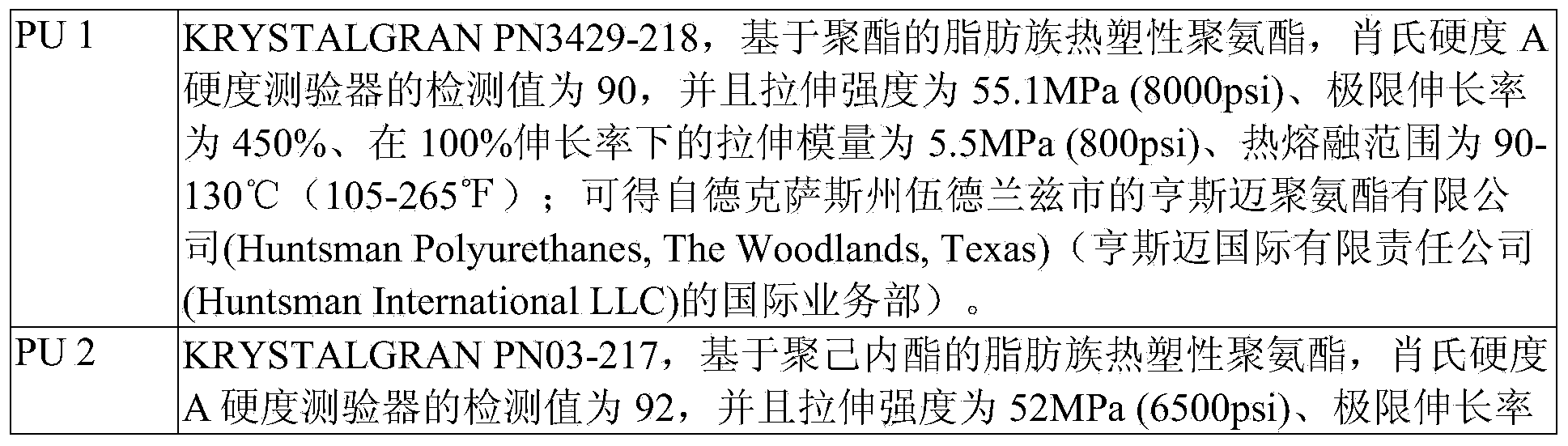

[0072] Table 1B: Results - Effect of various polyurethane resins, CAB and CAP resins

[0073]

[0074] *Breaks at elongation less than 50%.

[0075] Table 2A: Formulation - Effect of various PU:CAB and PU:CAP ratios

[0076] example

PU1

CAB3a

CAP1

17

60

40

0

18

45

55

0

19

30

70

0

[0077] 20

15

85

0

21

90

0

10

22

75

0

25

23

60

0

40

24

45

0

55

25

30

0

70

26

15

0

85

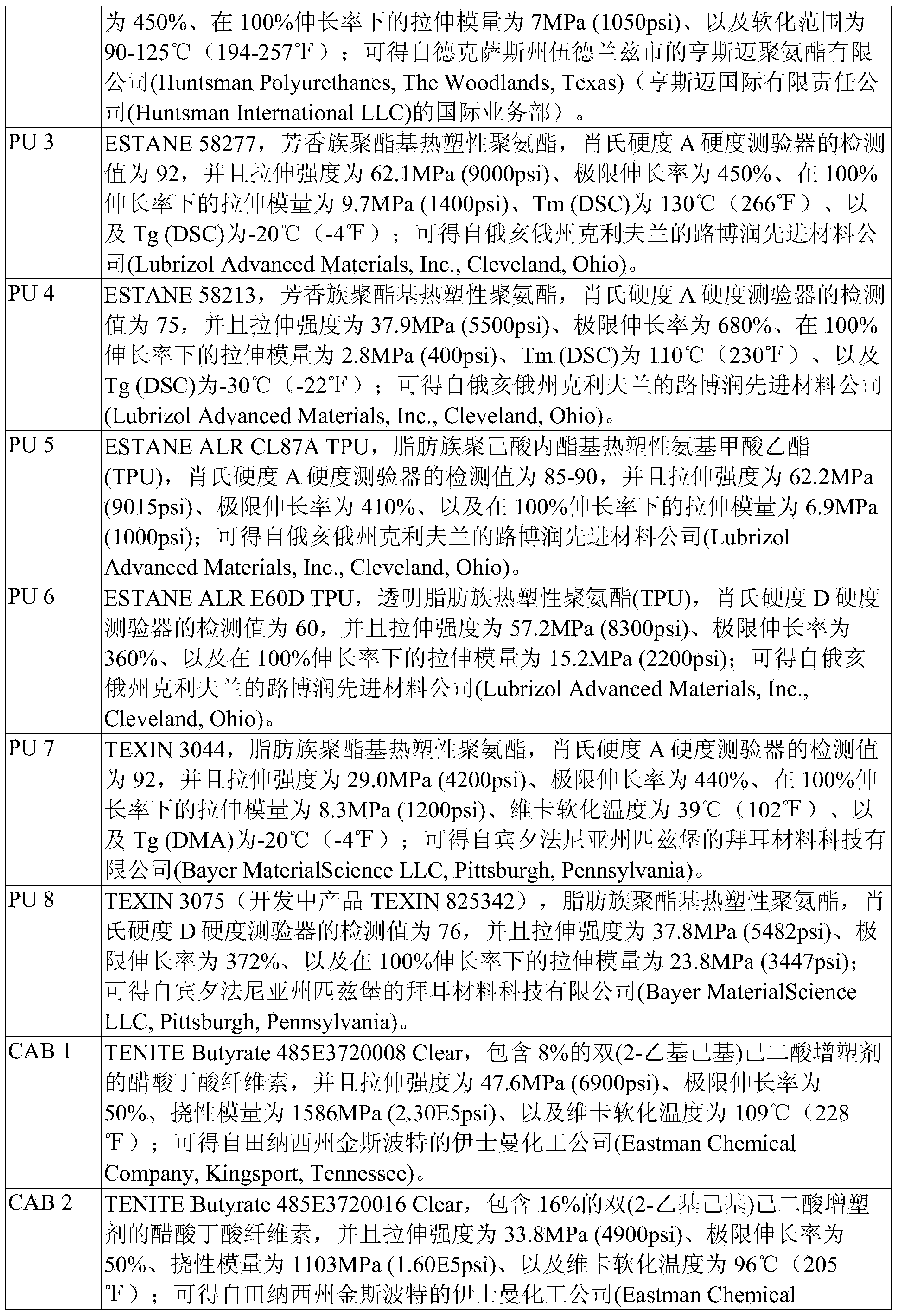

[0078] Table 2B: Results - Effect of various PU:CAB and PU:CAP ratios

[0079]

[0080] *Breaks at elongation less than 50%.

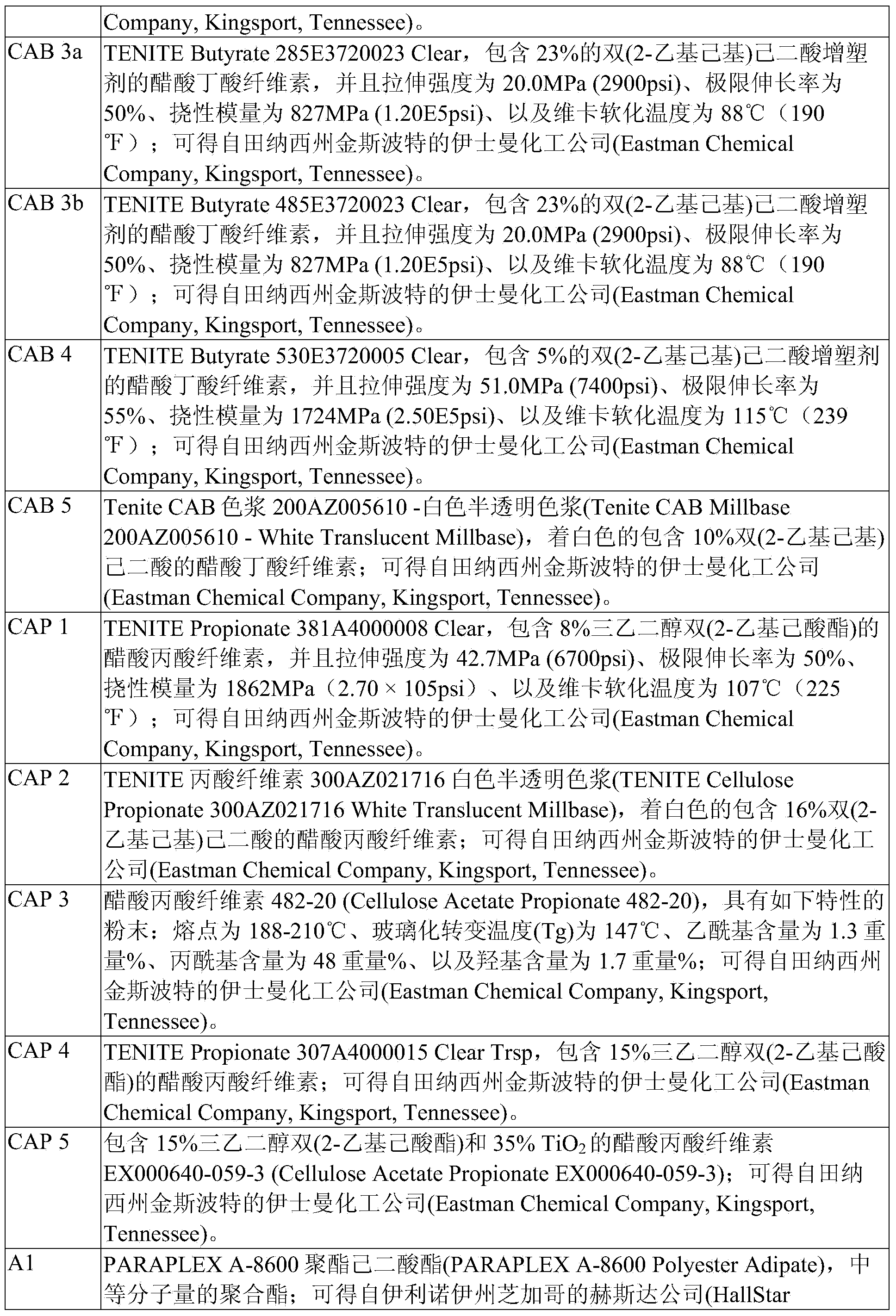

[0081] Table 3B: Results - Effect of Plasticizer Content

[0082]

[0083] Table 4A: Formulation - Effect of polymeric plasticizer

[0084] example

PU1

CAP1

CAP3

A1

A2

31

...

example 66

[0104] Example 66: Solvent cast membranes of the invention

[0105] The coating solution was prepared by combining 80% (w / w) N,N-dimethylformamide, 11% (w / w) PU1 and 9% (w / w) CAP3 in a closed container, and the container It was placed on a roll at 25°C for 16 hours, then it was heated at 65°C for 4 hours, followed by an additional 24 hours at 25°C on a roll. A viscous cloudy solution was obtained. The solution was coated onto a 96.5 micron (0.0038 inch) thick, untreated polyester film substrate using a 305 mm (12 inch) wide notched bar coater set at a gap of 0.41 mm (0.016 inch). The coated polyester substrate was dried at 65°C for 6 hours to obtain an approximately 75 micron (0.003 inch) thick film of the present invention on the polyester substrate. The film was carefully removed from the polyester base and the print density of the film was evaluated as described above. The results are shown in Table 9 below.

[0106] Table 9: Results - Print Density

[0107]

example 67

[0109] Multilayer films were prepared by coextruding the following layers:

[0110] 1. The first layer is a 1.0 mil blend of 55% by weight PU1 and 45% by weight CAP4,

[0111] 2. The second layer is 0.2 mil maleated polyethylene (available from Dow Chemical Co. under the trade designation Amplify GR209),

[0112]3. The third layer was 2.55 mils of 70 wt% Low Density Polyethylene (Equistar Petrothene NA271009 from LyondellBasell Corporation) and 30 wt% PolyOne 15077White CC00038580 White Pigment Masterbatch (PolyOne 15077White CC00038580White Pigment Masterbatch) (from PolyOne Corporation), a mixture of

[0113] 4. The fourth layer was 0.25 mil ethylene-acrylic acid copolymer (available from Dow Chemical Co. under the trade designation Primacor 1410).

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com