Intelligent adjustment type heat dissipation method and system for high-voltage frequency converter

A high-voltage inverter, intelligent adjustment technology, applied in the direction of using electric mode for temperature control, etc., can solve the problems of reducing the dustproof effect of the air inlet, dust blocking the air inlet, staff injury, etc., to improve the utilization rate of heat dissipation power, The effect of reducing noise and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

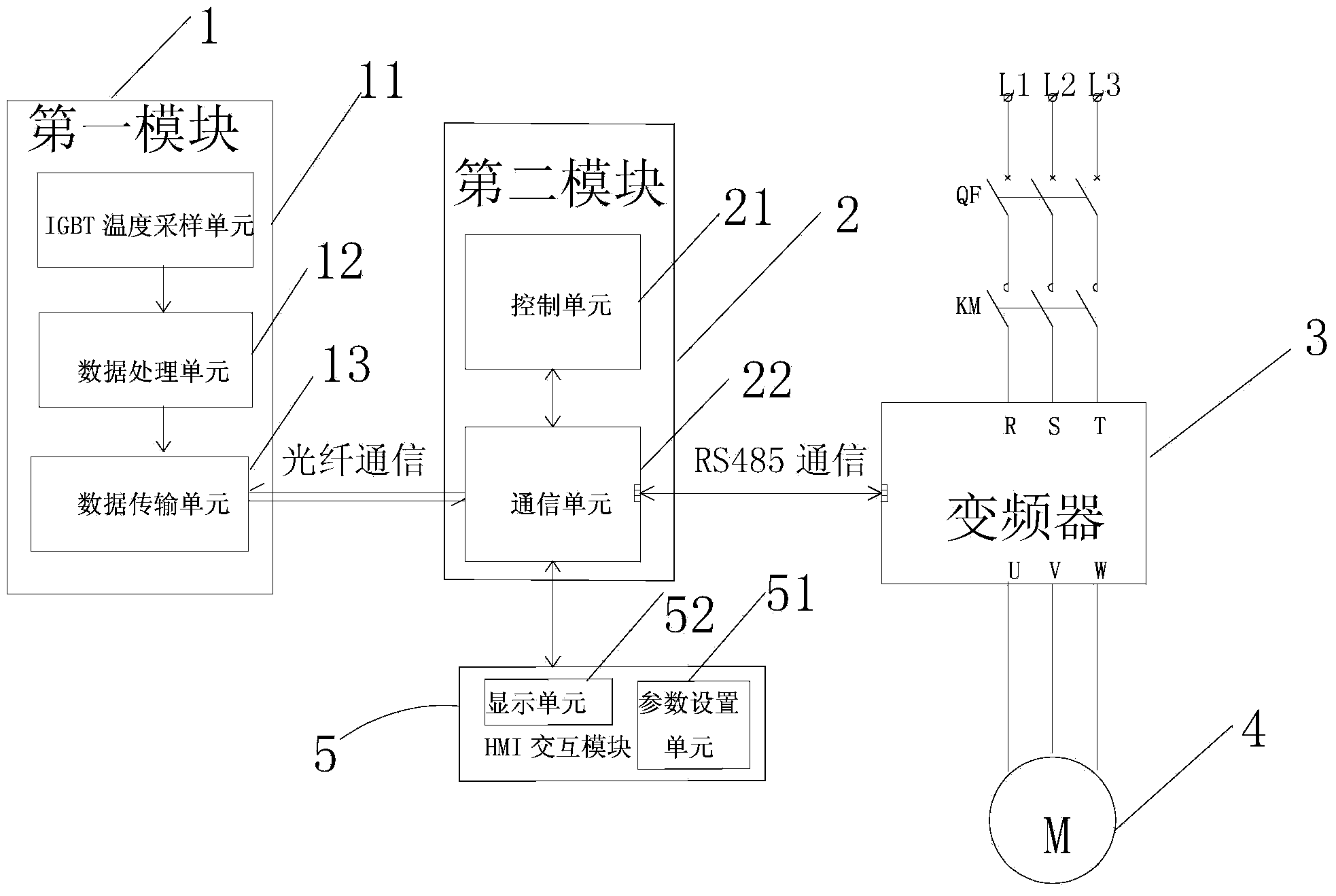

[0034] The following further describes the present invention with reference to the accompanying drawings of the specification and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

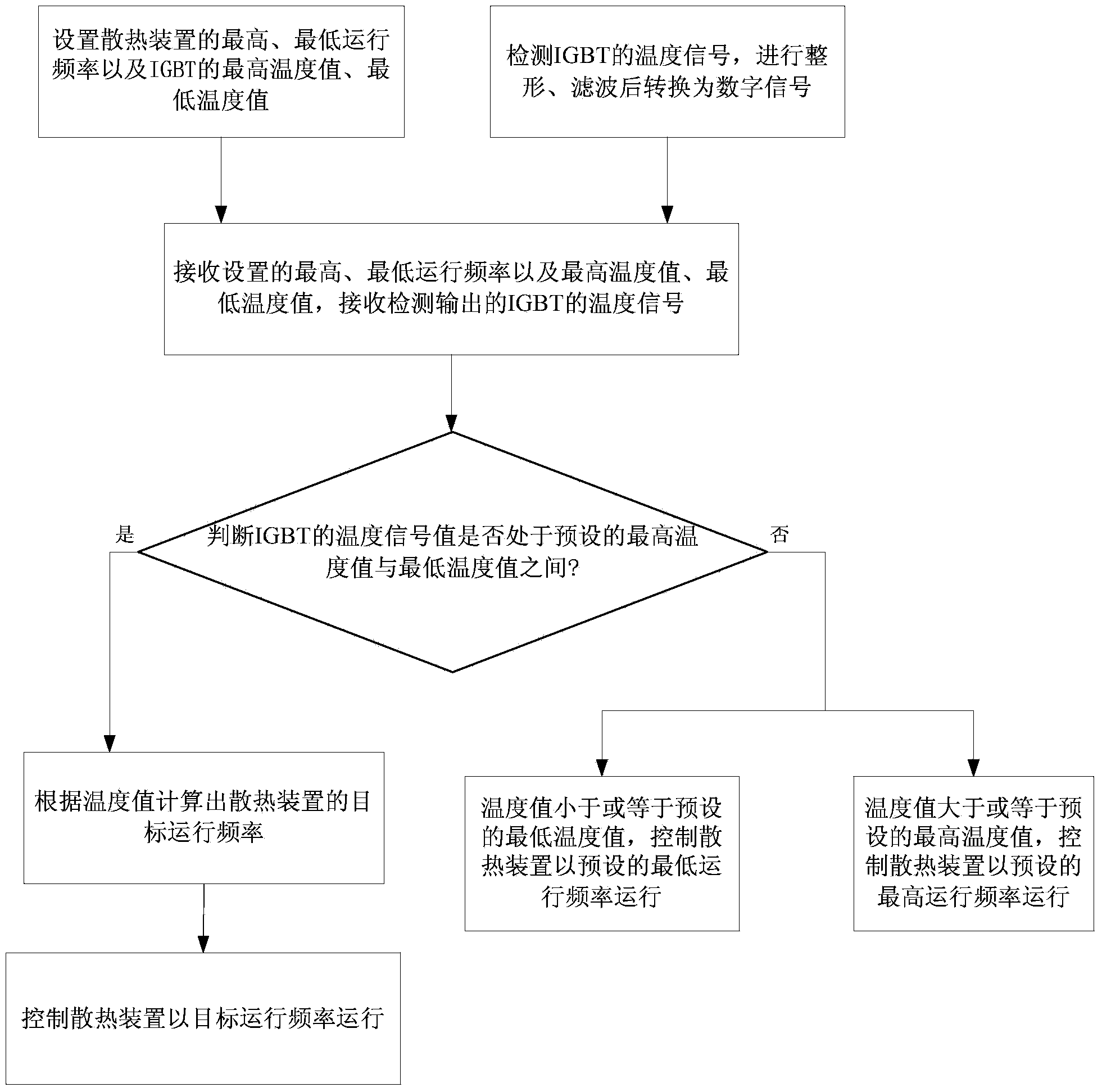

[0035] Such as figure 1 As shown, the present invention is used for the intelligent regulation and heat dissipation method of high-voltage frequency converter, the steps are:

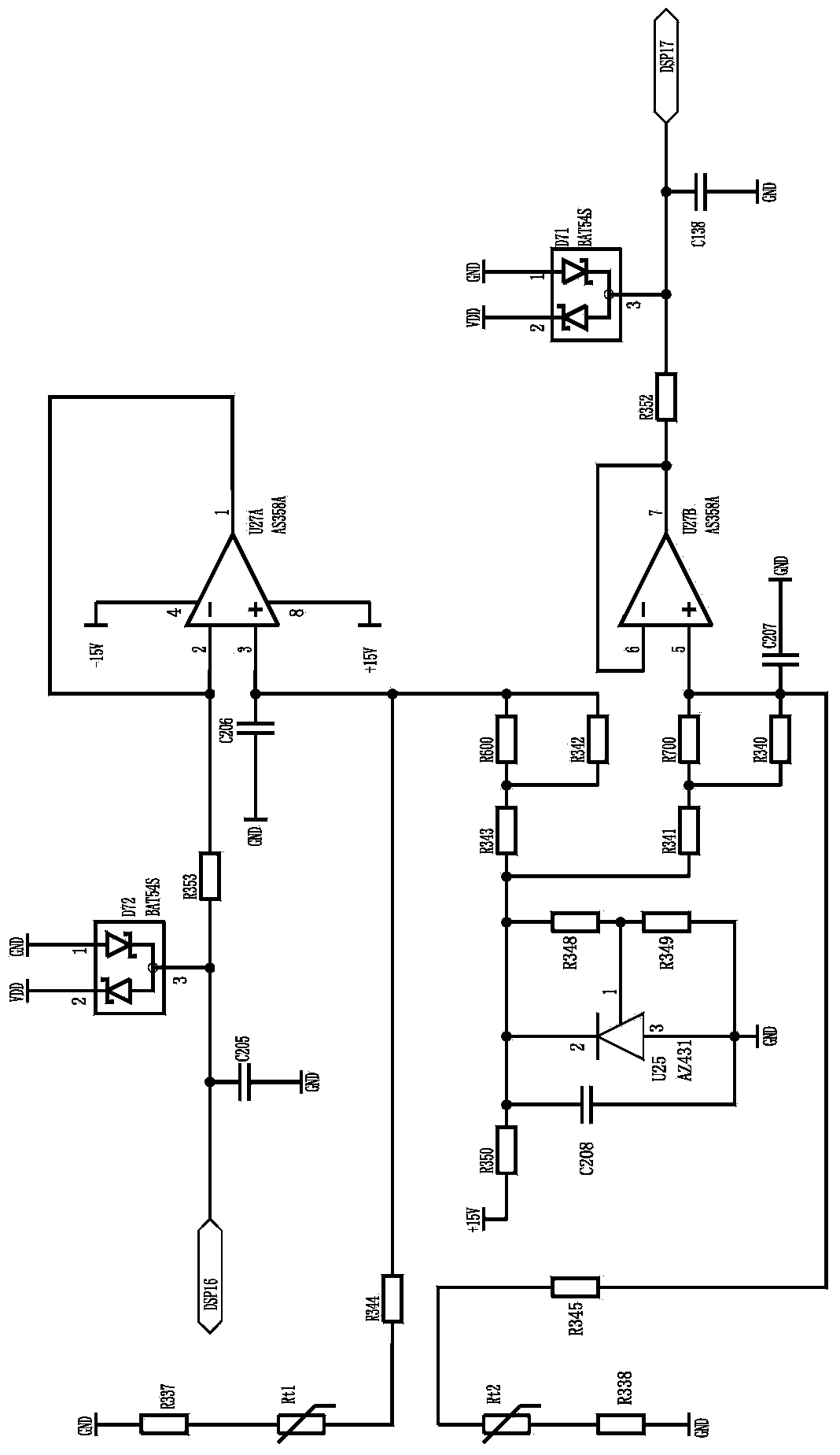

[0036] (1) Detect the temperature signal of the IGBT in real time, transform it into a digital signal and output it after shaping and filtering;

[0037] (2) Receive the temperature signal of the IGBT and make a judgment. When the temperature value is less than or equal to the preset minimum temperature value, control the heat sink 4 to operate at the preset minimum operating frequency; when the temperature value is greater than or equal to the preset maximum temperature When the value is set, the heat dissipation device 4 is controlled to run at the preset maximum operating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com