Mining method applicable to recovery of gentle-inclined/inclined thin ore body

A mining method and a gently tilting technology, applied in the field of open-field mining, can solve the problems of affecting the stability of the out-of-the-line transportation leveling, the large destructiveness of the out-of-the-line transportation leveling, and the low raking efficiency, so as to save the mining cost and reduce the mining cost. Preparing time, reducing safety hazards, and reducing the effect of cutting-to-cut ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

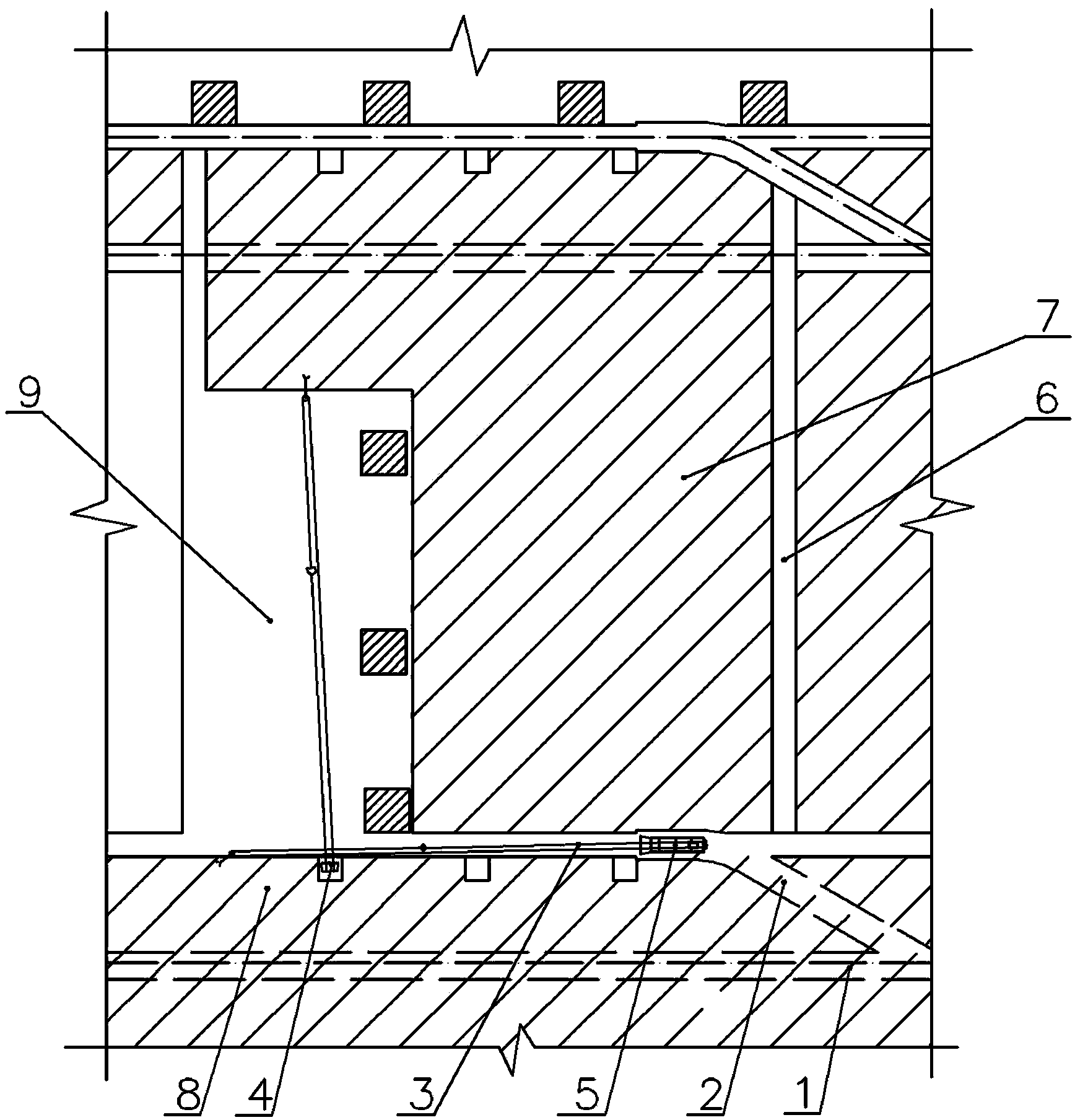

[0026] The mining method disclosed by the invention is suitable for the mining of gently inclined / inclined thin ore bodies. The stope is not divided into ore houses and ore pillars, and the free surface formed at the intersection of cutting the uphill and cutting the level road starts to retreat along the trend of the ore body. For mining, the bucket rock loader is used as the mining tool. The specific mining steps are as follows:

[0027] First, the stope is arranged along the strike of the ore body. Then, the out-of-vein transport roadway and the through-vein transport roadway are arranged on the floor of the ore body. Along the direction of the ore body, the out-of-vein transport roadway is excavated, and from the out-of-vein transportation roadway to the ore body at an included angle of 30 to 45 degrees, the through-vein transportation roadway is formed, and then the roadway is cut along the direction of the ore body in the ore body; then The electric rake chambers are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com