Preparation method for Bacillamide compound and Bacillamide precursor

A compound and precursor technology, applied in the field of bacterial culture to prepare compounds, can solve problems such as co-cultivation system instability and poor repeatability, and achieve the effects of low industrial production cost, high repeatability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

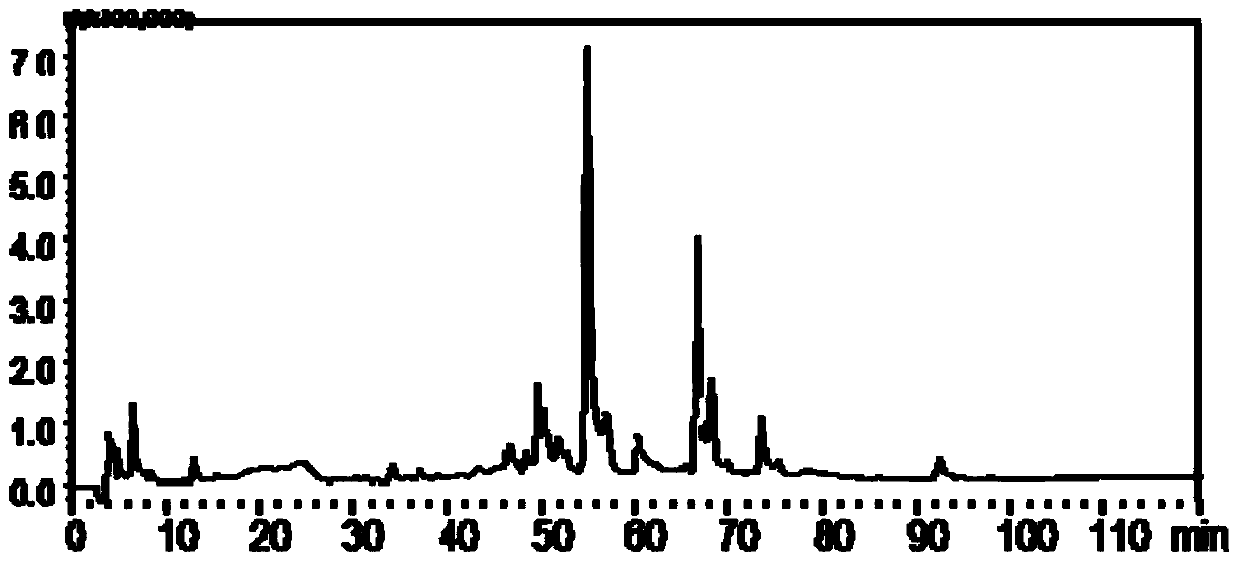

Image

Examples

Embodiment 1

[0050] 1) Inoculate actinomycetes (Streptomyces nodosus1A0101684, Beijing Beina Chuanglian Biotechnology Research Institute) into 500mL Erlenmeyer flasks, each containing 200mL of fermentation medium (based on 1L of fermentation medium, yeast extract 5g, glycerin 4g, soluble starch 1g, and seawater as the balance, adjust the pH of the fermentation medium to 7.5 with an acid-base buffer solution, and divide it into four groups, ABCD, wherein group A and group B were cultured statically at 28°C for 6 Day, Group C and Group D were cultured statically at 28°C for 10 days;

[0051] 2) Inoculate the Bacillus mycoides CGMCC1.197, which was cultivated on a shaker at 150 rpm for 24 hours, from Beijing Beina Chuanglian Biotechnology Research Institute, into the fermentation culture of the grown actinomycetes in step 1) Among them, the inoculation volume of group A and C was 400 μL, and the inoculation volume of group B and D was 1000 μL, and the symbiotic static culture was carried out ...

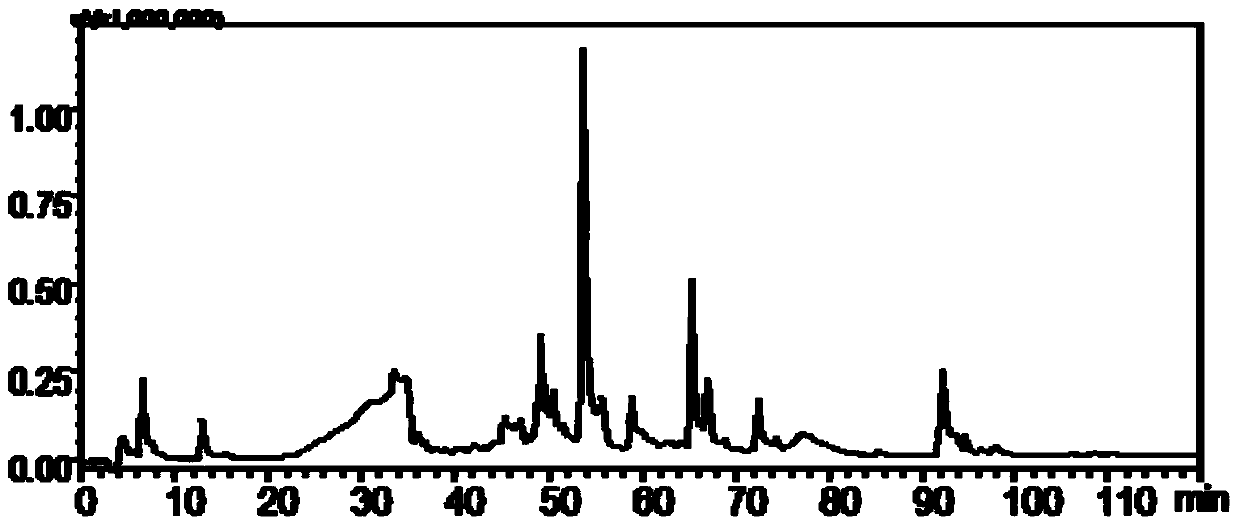

Embodiment 2

[0057] 1) Inoculate actinomycetes (Streptomyces nodosus1A0101684, Beijing Beina Chuanglian Biotechnology Research Institute) into 500mL Erlenmeyer flasks, each containing 250mL fermentation medium (based on 1L of fermentation medium, yeast extract 5g, glycerin 5g, and seawater as the balance, adjust the pH of the fermentation medium to 7.5) with an acid-base buffer solution, and culture it statically at 28°C for 7 days;

[0058] 2) Inoculate the Bacillus mycoides CGMCC1.197, which was cultured on a shaker at 140 rpm for 24 hours, from Beijing Beinan Chuanglian Biotechnology Research Institute, into the culture medium in which actinomycetes have grown in step 1) In , the inoculation volume was 1000 μL, and the symbiosis was statically cultured at 28°C for 15 days to obtain the co-cultivation fermentation medium;

[0059] 3) The co-cultivation fermentation medium obtained in each group was extracted with ethyl acetate and concentrated to dryness to obtain ethyl acetate fractions...

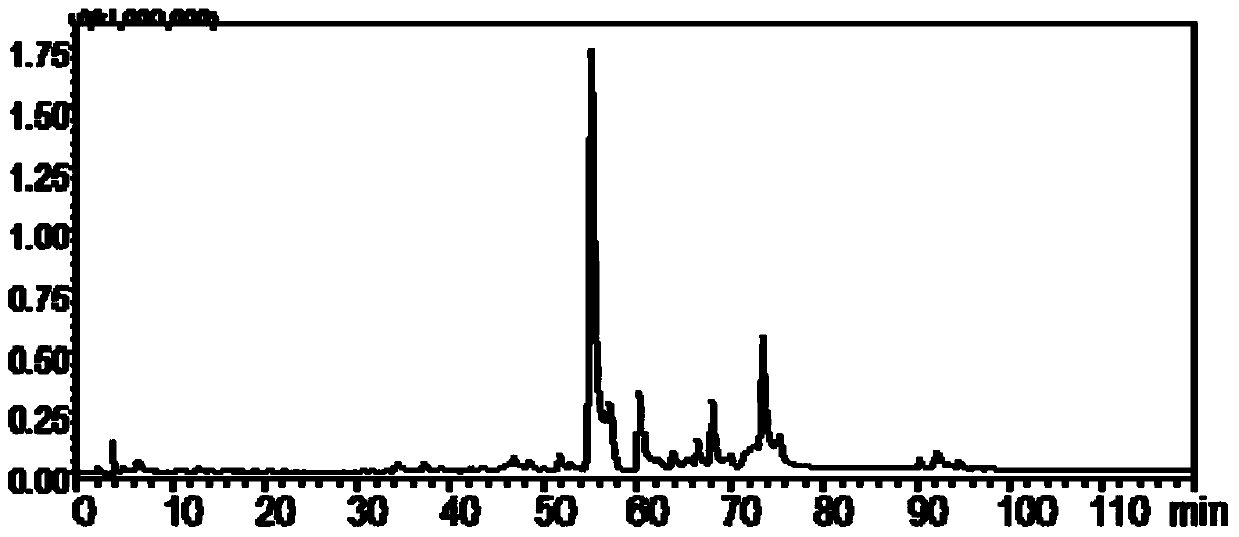

Embodiment 3

[0073] The ethyl acetate part obtained in Example 2 was separated by reverse phase chromatography to obtain a bacillamide compound and a bacillamide precursor. The filler used in the reversed-phase chromatography separation method is octadecyl bonded silica gel, and the mobile phase used is methanol-water. The specific process of the reversed-phase chromatography separation method is as follows: firstly use methanol aqueous solution formed by volume ratio 30:70 methanol and water to remove large polar impurities, and then use methanol aqueous solution formed by volume ratio 40:60 to obtain Bacillamide precursor, then eluted with methanol aqueous solution formed by methanol and water at a volume ratio of 50:50 to obtain bacillamide compounds B and C (eluted in time order), and eluted with methanol aqueous solution formed by 60:40 methanol and water to obtain bacillamide compound a.

[0074] Based on the fermentation medium, the yield of bacillamide precursor was 20 mg / L, the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com